Evaluation of cylinder bores

|

|

|||||||||||||||||||||||||||||||||

|

01—020 Evaluation of cylinder bores

|

|||||||||||||||||||||||||||||||||

|

|

|||||||||||||||||||||||||||||||||

|

|||||||||||||||||||||||||||||||||

|

|

|||||||||||||||||||||||||||||||||

|

Special tools

|

|||||||||||||||||||||||||||||||||

|

|

|||||||||||||||||||||||||||||||||

|

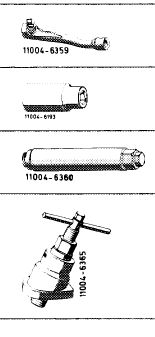

Box wrench socket, open, 17 mm, 1/2″ square for injection lines

|

|

000 589 68 03 00

|

|||||||||||||||||||||||||||||||

|

Socket 27 mm, 1/2″ square

|

001 589 65 09 00

|

||||||||||||||||||||||||||||||||

|

Socket wrench for threaded ring of prechamber

|

615 589 00 07 00

|

||||||||||||||||||||||||||||||||

|

PUIIer for prechambers

|

615 589 00 33 00

|

||||||||||||||||||||||||||||||||

|

|

|||||||||||||||||||||||||||||||||

|

Conventional tool

|

|||||||||||||||||||||||||||||||||

|

|

|||||||||||||||||||||||||||||||||

|

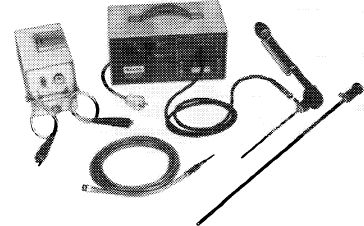

Cylinder illuminating lamp

|

Karl Storz GmbH, 7200 Tuttlingen MotoskopTW(Kaltlicht)

with lens probes 103 26 CW (750 mm) and 103 26 CT (210 mm).

|

||||||||||||||||||||||||||||||||

|

|

|||||||||||||||||||||||||||||||||

|

Note

|

|||||||||||||||||||||||||||||||||

|

|

|||||||||||||||||||||||||||||||||

|

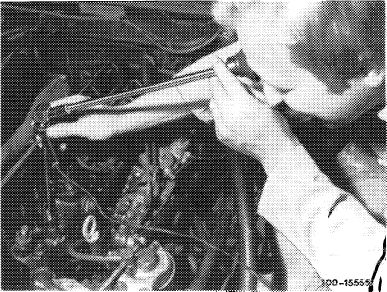

A visual checkup can be made with cylinder head in place by means of a cylinder illuminating lamp. For this purpose, the prechambers must be removed (01-417).

|

|

||||||||||||||||||||||||||||||||

|

|

|||||||||||||||||||||||||||||||||

|

103-15713

|

|||||||||||||||||||||||||||||||||

|

|

|||||||||||||||||||||||||||||||||

|

01.8-020/1 F2

|

|||||||||||||||||||||||||||||||||

|

|

|||||||||||||||||||||||||||||||||

|

|

|||

|

When evaluating scored or streaky cylinder walls, it is often difficult for a workshop to decide whether the damage is already extensive and requires removal or repair of the engine, or whether the evidence is harmless. The following instructions will help in making an expert and correct decision.

|

|

||

|

|

|||

|

With regard to marks on cylinder walls, the first important difference is between “optical streaks” and “seizure streaks”. As a rule, “optical streaks” are about 3 mm wide, they are produced by the piston ring gaps and do not destroy honing structure; “seizure streaks”, however, obliterate honing structure.

With streaks in direction of “land” (in direction of piston pin) shaft streaks or seizures are not possible, since there is no contact between piston skirt and cylinder liner.

|

|||

|

|

|||

|

01.8-020/2 F2

|

|||

|

|

|||

Poprzedni

Checking cylinders for leaks

Nowsze