Checking cylinders for leaks

|

|

||||

|

01—015 Checking cylinders for leaks

|

||||

|

|

||||

|

Data

|

||||

|

|

||||

|

Total pressure loss

On valves and cylinder head gasket

On pistons and piston rings

|

max. 25 % max. 10% max. 20 %

|

|||

|

|

||||

|

Special tool

|

||||

|

|

||||

|

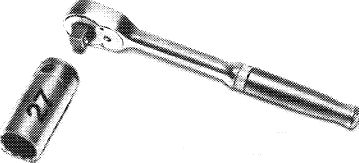

Socket 27 mm, 1/2″ square socket for rotating engine

|

|

000 589 65 09 00

|

||

|

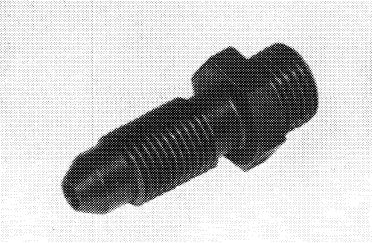

Screw fitting for glow plug bore

|

617 589 03 21 00

|

|||

|

|

||||

|

Conventional tool

|

||||

|

|

||||

|

Cylinder leak tester

|

e.g. made by Bosch, EFAW 210 A made by SUN, CLT 228

|

|||

|

|

||||

|

Checking

|

||||

|

|

||||

|

1 Run engine up to operating temperature.

|

||||

|

|

||||

|

2 Unscrew pencil element glow plugs.

|

||||

|

|

||||

|

3 Remove air cleaner cap.

|

||||

|

|

||||

|

4 Remove oil filler plug.

|

||||

|

|

||||

|

5 Remove radiator cap and top up coolant.

|

||||

|

|

||||

|

6 Enter screw fitting into glow plug bore of 1st cylinder.

|

|

|||

|

|

||||

|

«5?J –

|

||||

|

|

||||

|

01.8-015/1 F2

|

||||

|

|

||||

|

|

|||

|

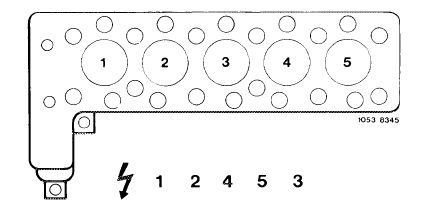

7 Set piston of 1st cylinder to ignition TDC. For this purpose, rotate engine at crankshaft by means of tool combination.

8 Connect cylinder leak tester to a compressed air system. Calibrate tester.

9 Screw connecting hose of tester to screw fitting. Crankshaft should not rotate.

|

|

||

|

|

|||

|

1100-6498/1

|

|||

|

|

|||

|

10 Read pressure loss on tester.

11 Check by listening whether pressure escapes via intake pipe, exhaust, oil filler cap, glow plug bore of adjacent cylinder or radiator cap.

12 Check all cylinders in ignition sequence.

|

|

||

|

|

|||

|

Note: There is the possibility that the piston ring gaps of individual pistons are directly one above the other, so that the test result will be misrepresented.

When in doubt, continue running vehicle and check cylinders for leaks once again later on.

|

|||

|

|

|||

|

01.8-015/2 F2

|

|||

|

|

|||

Poprzedni

Checking compression pressure

Nowsze