Cylinder head bolts and tightening of cylinder head bolts

|

|

|||||||||||||||||||||||||||||||

|

01—405 Cylinder head bolts and tightening of cylinder head bolts

|

|||||||||||||||||||||||||||||||

|

|

|||||||||||||||||||||||||||||||

|

Tightening torques and angle of rotation for cylinder head bolts on cold engine

|

|||||||||||||||||||||||||||||||

|

|

|||||||||||||||||||||||||||||||

|

Cylinder head bolt version

|

Tightening steps Nm

|

Angle of rotation

|

|||||||||||||||||||||||||||||

|

|

|||||||||||||||||||||||||||||||

|

Hex. socket cylinder head bolts (cylinder head bolts with cylindrical shank)

|

|

||||||||||||||||||||||||||||||

|

|

|||||||||||||||||||||||||||||||

|

Step 3

|

100

|

||||||||||||||||||||||||||||||

|

|

|||||||||||||||||||||||||||||||

|

Double hex. socket cylinder head bolts (necked-down cylinder head bolts)

|

|

||||||||||||||||||||||||||||||

|

|

|||||||||||||||||||||||||||||||

|

Step 4

|

90c

|

||||||||||||||||||||||||||||||

|

|

|||||||||||||||||||||||||||||||

|

Tighten M 8~cylinder head bolts by means of Allen wrench with tommy handle.

|

|||||||||||||||||||||||||||||||

|

|

|||||||||||||||||||||||||||||||

|

Dimensions of double hex cylinder head bolts

|

|||||||||||||||||||||||||||||||

|

|

|||||||||||||||||||||||||||||||

|

Thread dia.

|

Length when new

|

Max. length (renew)

|

|

||||||||||||||||||||||||||||

|

M 12 M 12 M 12

|

104 119 144

|

105.5 120.5 145.0

|

|||||||||||||||||||||||||||||

|

|

|||||||||||||||||||||||||||||||

|

01.8-405/1 F2

|

|||||||||||||||||||||||||||||||

|

|

|||||||||||||||||||||||||||||||

|

|

|||||

|

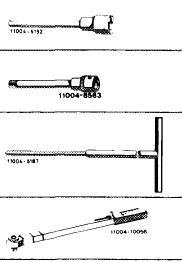

Special tools

|

|||||

|

|

|||||

|

Socket 10 mm, 1/2″ square, 140 mm long for hex. socket cylinder head bolts

|

|

000 589 05 07 00

|

|||

|

Socket 1/2″ square, 140 mm long for double hex. socket cylinder head bolts

|

617 589 00 10 00

|

||||

|

Screwdriver (Allen wrench) with tommy handle for hex. socket screws 6 mm, 440 mm long

|

116 589 03 07 00

|

||||

|

Torque wrench with plug-in ratchet 1/2″ square, 40-200 Nm

|

001 589 67 21 00

|

||||

|

|

|||||

|

Notes

|

|||||

|

|

|||||

|

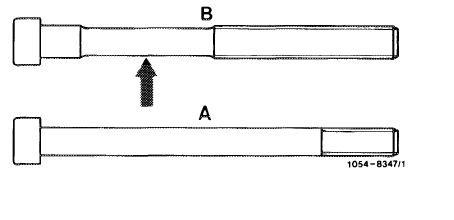

To obtain a more uniform and higher initial bolt preload, the cylinder head bolts with cylindrical shank (A) used up to now on engine 617.950 have been replaced by necked-down cylinder head bolts (B) starting February 1979. On engines 617.951/952, they are installed from start of series.

|

|

||||

|

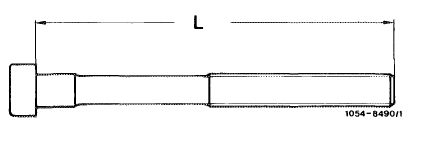

A Cylinder head bolt with cylindrical shank B Cylinder head bolt with necked-down shaft

|

|||||

|

These cylinder head bolts have a reduced shank section (arrow) and longer threads.

|

|||||

|

|

|||||

|

01.8-405/2 F2

|

|||||

|

|

|||||

|

|

|||||||||||||||||||||||||||||

|

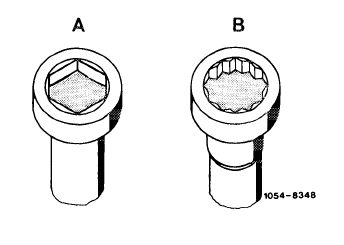

In installed condition, the cylinder head bolts are identified by the double hex. socket (B), formerly hex. socket (A).

|

|||||||||||||||||||||||||||||

|

|

|||||||||||||||||||||||||||||

|

A Hex. socket cylinder head bolt

B Double hex. socket cylinder head bolt

|

|

||||||||||||||||||||||||||||

|

|

|||||||||||||||||||||||||||||

|

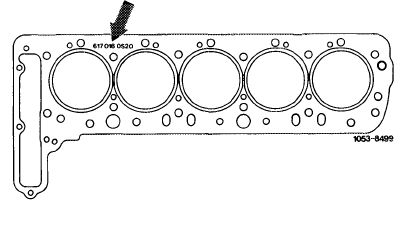

The cylinder head gasket has been simultaneously provided with an improved impregnation and the washers have been made harder.

The cylinder head gasket is identified by the impressed part no., the washers by the olive-colored chromate surface.

Cylinder head gasket part no. 617 016 05 20.

|

|

||||||||||||||||||||||||||||

|

|

|||||||||||||||||||||||||||||

|

The double hex. socket cylinder head bolts are tightened to an initial torque preload and an angle of rotation (refer to table).

Since these cylinder head bolts are subject to a permanent elongation upon tightening, they must be replaced as soon as the max. longitudinal dimensions shown in table below are exceeded.

|

|

||||||||||||||||||||||||||||

|

|

|||||||||||||||||||||||||||||

|

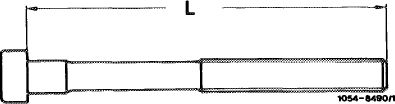

Dimensions of cylinder head bolts

|

|||||||||||||||||||||||||||||

|

|

|||||||||||||||||||||||||||||

|

Thread dia.

|

Length Max. length (L)

when new (L) (renew)

|

||||||||||||||||||||||||||||

|

|

|||||||||||||||||||||||||||||

|

|||||||||||||||||||||||||||||

|

|

|||||||||||||||||||||||||||||

|

Owing to the permanent elongation, the threaded bores in cylinder crankcase have been made longer and the cylinder head bolts have been shortened by 1 mm.

|

|||||||||||||||||||||||||||||

|

|

|||||||||||||||||||||||||||||

|

01.8-405/3 F2

|

|||||||||||||||||||||||||||||

|

|

|||||||||||||||||||||||||||||

|

|

|||

|

For this reason, they must not be installed in engine 617.950 with hex. socket cylinder head bolts.

The above applies also to the installation of short blocks and new cylinder crankcases.

Always use the cylinder bolt version of removed engine.

It is also not permitted to install mixed cylinder head bolts on one and the same engine.

|

|||

|

|

|||

|

In the event of repairs on engines with double hex. socket cylinder head bolts only the cylinder head gasket with improved impregnation and harder washers may be installed.

Tighten cylinder head bolts to initial torque preload and angle of rotation torque.

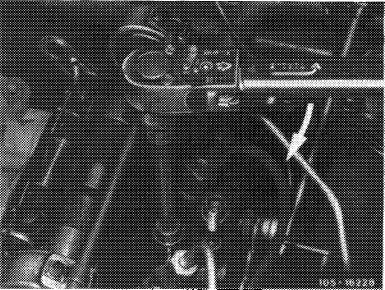

Estimate angle of rotation. For this purpose, place adjustable torque wrench in release position (locked) into plug-in ratchet. Position adjustable torque wrench with plug-in ratchet longitudinally in relation to engine and turn until wrench is positioned transverse to engine.

|

|

||

|

|

|||

|

When tightening to angle of rotation torque, do not use a bending bar-torque wrench.

On engine 617.950 with hex. socket cylinder head bolts, the cylinder head gasket with improved impregnation and harder washers may also be installed.

Tighten hex. socket cylinder head bolts always according to torque.

|

|||

|

|

|||

|

When tightening according to torque, the former warm tightening is no longer required. Instead, a 10-minute setting interval must be maintained between tightening step 2 and 3 (refer to table). In addition, tightening step 3 has been increased by 10 Nm to 100 Nm.

|

|||

|

|

|||

|

01.8-405/4 F2

|

|||

|

|

|||

|

|

|||

|

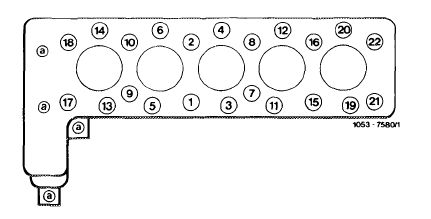

Tighten cylinder head bolts in steps in sequence of tightening diagram.

Do not loosen cylinder head bolts after setting interval, but directly continue tightening.

|

|

||

|

|

|||

|

Independent of cylinder head bolt version, retighten-ing of cylinder head bolts is no longer required during inspection 1000—1500 km or in the event of repairs after approx. 100—1500 km.

|

|||

|

|

|||

|

01.8-405/5 F 2

|

|||

|

|

|||