Checking fuel pump and bypass valve

|

|

||||||||||||||||||||||||||||||

|

07.1—145 Checking fuel pump and bypass valve

|

||||||||||||||||||||||||||||||

|

|

||||||||||||||||||||||||||||||

|

Job no. of flat rates or standard texts and flat rates data 07—8800 or 5700.

|

||||||||||||||||||||||||||||||

|

|

||||||||||||||||||||||||||||||

|

Test values

|

||||||||||||||||||||||||||||||

|

|

||||||||||||||||||||||||||||||

|

Bosch designation

|

FP/K22MW8, MW22

|

|||||||||||||||||||||||||||||

|

|

||||||||||||||||||||||||||||||

|

Measuring point

|

prior to fuel pump inlet

|

|||||||||||||||||||||||||||||

|

|

||||||||||||||||||||||||||||||

|

Vacuum

|

||||||||||||||||||||||||||||||

|

|

||||||||||||||||||||||||||||||

|

at idle speed bar vacuum

|

0.1

|

|||||||||||||||||||||||||||||

|

|

||||||||||||||||||||||||||||||

|

Measuring point

|

between fuel pump and main fuel filter

|

|||||||||||||||||||||||||||||

|

|

||||||||||||||||||||||||||||||

|

Delivery pressure

|

at idle speed

bar gauge pressure

|

0.6-0.8

|

||||||||||||||||||||||||||||

|

|

||||||||||||||||||||||||||||||

|

at 30007min

bar gauge pressure

|

min. 0.8

|

|||||||||||||||||||||||||||||

|

|

||||||||||||||||||||||||||||||

|

at idle speed

bar gauge pressure

|

min. 1.1

|

|||||||||||||||||||||||||||||

|

|

||||||||||||||||||||||||||||||

|

Delivery end pressure

|

||||||||||||||||||||||||||||||

|

|

||||||||||||||||||||||||||||||

|

at 3000/min

bar gauge pressure

|

min. 1.3

|

|||||||||||||||||||||||||||||

|

|

||||||||||||||||||||||||||||||

|

||||||||||||||||||||||||||||||

|

|

||||||||||||||||||||||||||||||

|

Special tools

|

||||||||||||||||||||||||||||||

|

|

||||||||||||||||||||||||||||||

|

Clip for fuel hose

|

|

000 589 40 37 00

|

||||||||||||||||||||||||||||

|

|

||||||||||||||||||||||||||||||

|

Tester for fuel pump

|

|

617 589 04 21 00

|

||||||||||||||||||||||||||||

|

|

||||||||||||||||||||||||||||||

|

07.1.8-145/1 F3

|

||||||||||||||||||||||||||||||

|

|

||||||||||||||||||||||||||||||

|

|

|||

|

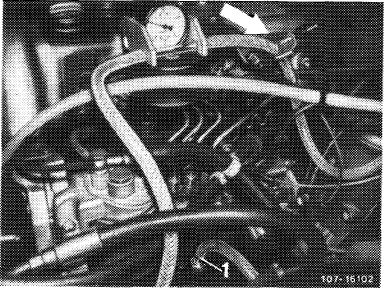

Measuring negative pressure

|

|

||

|

1 Connect tester to fuel inlet (1) on fuel pump. For this purpose, remove fuel feed line. Vent injection system (07.1 — 140).

|

|||

|

|

|||

|

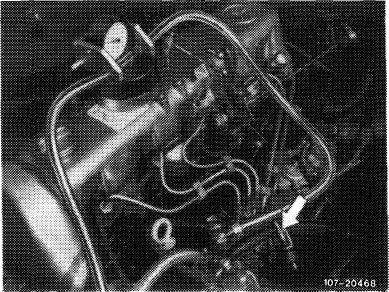

Measure vacuum pressure at idle speed. To do so, use clip to nip hose (arrow) at tester downstream of pressure gage.

If system fails to reach value of 0.1 bar vacuum, exchange suction and delivery valves or fuel pump (07.1-240).

|

|||

|

|

|||

|

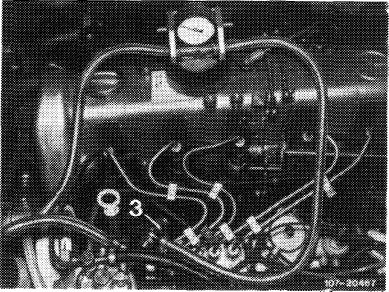

Checking fuel feed pressure

|

|

||

|

2 Unscrew fuel line (3) on fuel main filter.

3 Connect tester. For this purpose, connect fuel line to hose line for tester with a double hollow screw and closing nut. Connect other hose line of tester to fuel filter.

|

|||

|

|

|||

|

4 Vent injection system (07.1-140).

5 Warm up engine.

6 Measure fuel feed pressure at idle speed and 3000/min.

0.6—0.8 bar gauge pressure at idle speed. Min. 0.8 bar gauge pressure at 3000/min.

|

|||

|

|

|||

|

07.1.8-145/2 F2

|

|||

|

|

|||

|

|

||||

|

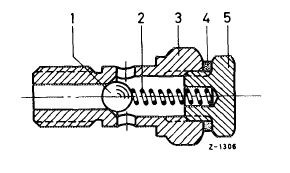

7 What to do in case feed pressure is inadequate:

a) Check bypass valve, removing, disassembling and cleaning for this purpose.

Increase preloading of compression spring (2), lengthening spring to 26—27 mm.

|

|

|||

|

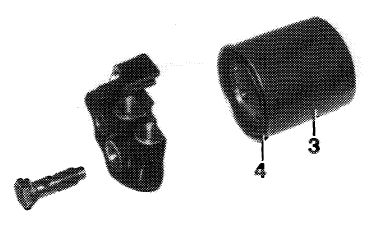

1 Ball

2 Compression spring

3 Body

|

4 Sealing ring

5 Screw plug

|

|||

|

|

||||

|

b) Check fuel filter for clogging. If necessary, fit new filter element with body (3) and sealing ring (4).

c) Exchange suction and delivery valves or fuel pump (07.1-235).

|

|

|||

|

|

||||

|

107-113®!

|

||||

|

|

||||

|

Checking final fuel feed pressure

|

|

|||

|

8 Using clip (arrow), nip fuel return hose.

9 Measure final fuel feed pressure at idle speed and 3000/min.

Min. 1.1 bar gauge pressure at idle speed. Min. 1.3 bar gauge pressure at 3000/min.

|

||||

|

|

||||

|

10 If final feed pressure is inadequate, exchange suction and delivery valves or fuel pump (07.1-235).

|

||||

|

|

||||

|

07.1.8-145/3 F2

|

||||

|

|

||||

Poprzedni