Instructions for renewing and tensioning V-belts

|

|

|||||

|

13—335 Instructions for renewing and tensioning V-belts

|

|||||

|

|

|||||

|

Adjusting values

|

|||||

|

|

|||||

|

V-belts

(width of profile in mm)

|

New V-belts (KG-scale on measuring instrument)

|

Used V-belts (KG-scale on measuring instrument)

|

|||

|

|

|||||

|

9.5 12.5

|

30 50

|

20-25 40-45

|

|||

|

|

|||||

|

Conventional tool

|

|||||

|

|

|||||

|

e.g. made by Gates GmbH, Gravener StraBe 191-193, D-4018 Langenfeld 2

|

|||||

|

|

|||||

|

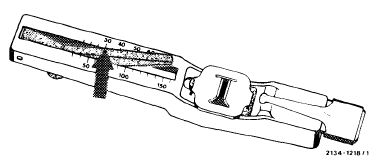

Measuring instrument (Krikit)

|

|||||

|

|

|||||

|

e.g. Gates Rubber Company 999 S. Broadway USA-80217 Denver/Colorado

|

|||||

|

|

|||||

|

Checking condition of V-belts

|

|||||

|

|

|||||

|

Renew cracked, porous, burnt or worn V-belts.

|

|||||

|

|

|||||

|

Checking tension

|

|

||||

|

For handling of instrument refer to operating instructions and tensioning V-belts (13—340).

The specified adjusting values refer to KG-scale of measuring instrument (arrow).

|

|||||

|

|

|||||

|

13.2-335/1 F3

|

|||||

|

|

|||||

|

|

||

|

Used V-belts

|

||

|

|

||

|

Check tension of V-belts and compare with values for used V-belts (e.g. V-belt, width of profile 9.5 mm = adjusting value 20—25) shown on table and reten-sion accordingly, if required.

|

||

|

|

||

|

Mounting and tensioning of new V-belts

Perfect assembly of a V-belt requires loosening of respective secondary unit or tensioning device of V-belt to the extent that the V-belt can be easily mounted. In addition, the running surfaces on V-belt pulleys should be free of burr, rust and dirt.

Keep away from oil, grease, chemicals. Do not use belt wax or similar compounds. Then make sure of optimal adjustment of belt tension (for adjusting values refer to table) to avoid complaints such as squealing V-belts and short life.

During maintenance jobs, mount V-belt prior to engine checkup and tension to value for new V-belts named in table (e.g. V-belt, width of profile 9.5 mm = adjusting value 30).

If possible, run engine approx. 10—15 minutes with all consumers connected. Then check tension. The value measured in this manner should be in agreement with value for used V-belts shown on table (e.g. V-belt, width of profile 9.5 mm = adjusting value 20—25). If it is less, retension V-belt to this value.

If the engine cannot be run in shop, check V-belt tension during final inspection or following a test drive.

|

||

|

|

||

|

13.2-335/2 F3

|

||

|

|

||