Knocking-out and inserting steel balls for main oil ducts

|

|

||||||||||||||||||||||||||||||||||||

|

01—130 Knocking-out and inserting steel balls for main oil ducts

|

||||||||||||||||||||||||||||||||||||

|

|

||||||||||||||||||||||||||||||||||||

|

Tightening torques

|

Nm

|

|||||||||||||||||||||||||||||||||||

|

|

||||||||||||||||||||||||||||||||||||

|

||||||||||||||||||||||||||||||||||||

|

|

||||||||||||||||||||||||||||||||||||

|

Necked-down screw for driven plate and flywheel

|

initial torque

|

40

|

||||||||||||||||||||||||||||||||||

|

torque angle

|

90°-100°

|

|||||||||||||||||||||||||||||||||||

|

|

||||||||||||||||||||||||||||||||||||

|

Note

|

|

|||||||||||||||||||||||||||||||||||

|

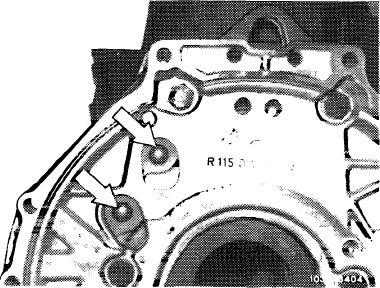

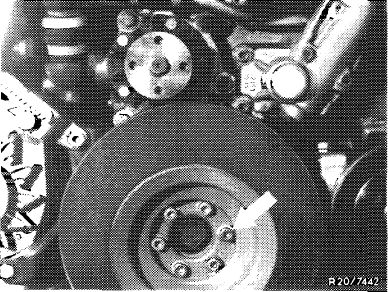

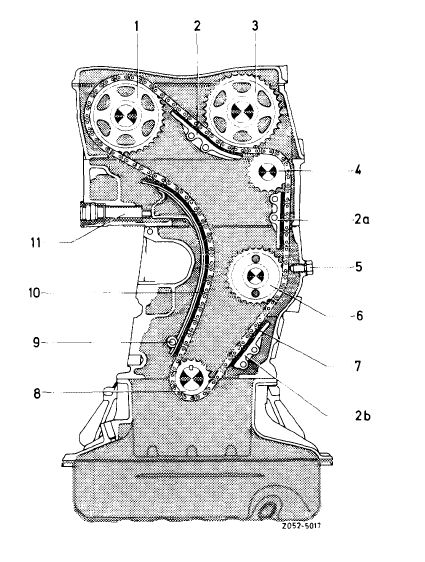

Since October 1976 the 2 main oil ducts (arrows) in cylinder crankcase at transmission end are closed by means of steel balls 15 mm dia. VO DIN 5401 part no. 005401 515001.

|

||||||||||||||||||||||||||||||||||||

|

|

||||||||||||||||||||||||||||||||||||

|

For cleaning main oil ducts during engine repairs, the steel balls must be knocked-out from direction of front end of engine.

Undamaged steel balls can be used several times without refinishing ball seat in crankcase.

Damaged and rusty steel balls should be replaced.

|

|

|||||||||||||||||||||||||||||||||||

|

|

||||||||||||||||||||||||||||||||||||

|

01.2-130/1 F3

|

||||||||||||||||||||||||||||||||||||

|

|

||||||||||||||||||||||||||||||||||||

|

|

|||

|

Knocking-out steel ball in upper main oil duct

|

|

||

|

1 Remove transmission.

|

|||

|

2 Remove flywheel (03-410).

|

|||

|

|

|||

|

3 Remove radiator (20-420).

|

|

||

|

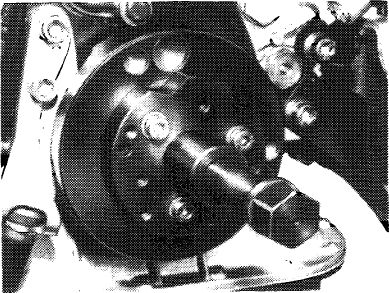

4 Remove vibration damper (03—340).

|

|||

|

|

|||

|

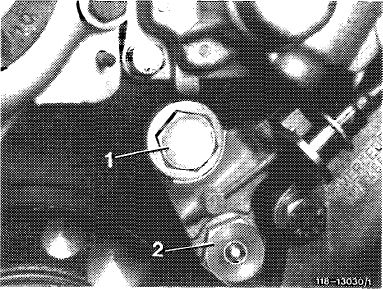

5 Unscrew closing plug (1) and screw oil pressure relief valve out of main oil duct.

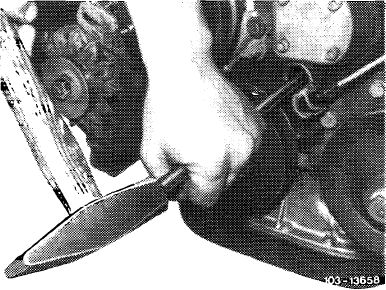

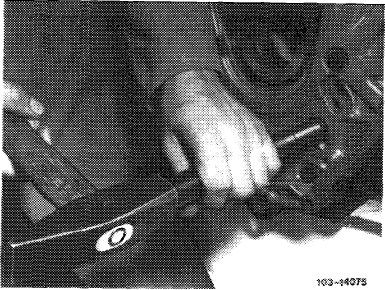

6 Knock-out steel ball from direction of engine front end by means of a round steel bar 13 mm dia. and approx. 700 mm long.

|

|

||

|

|

|||

|

Knocking-out steel ball in lower main oil duct

|

|

||

|

1 Remove transmission.

|

|||

|

2 Remove flywheel (03-410).

|

|||

|

|

|||

|

01.2-130/2 F3

|

|||

|

|

|||

|

|

|||

|

3 Remove radiator (20-420).

4 Remove vibration damper and compensating weight (03-340).

|

103-8363

|

||

|

|

|||

|

5 Remove complete oil pan (01—310).

6 Remove oil pump (18-210).

|

|

||

|

|

|||

|

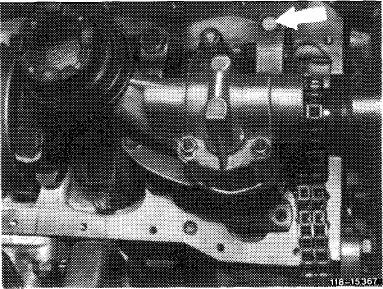

7 Remove slide rail (2b) in crankcase (05—340).

8 Knock-out steel ball from direction of engine front end by means of a round steel bar 13 mm dia. and approx. 700 mm long.

|

|

||

|

|

|||

|

01.2-130/3 F3

|

|||

|

|

|||

|

|

||||

|

Closing main oil duct

|

||||

|

|

||||

|

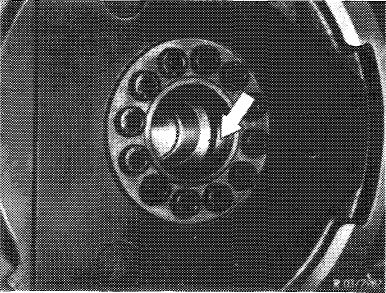

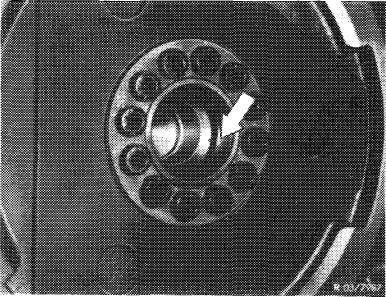

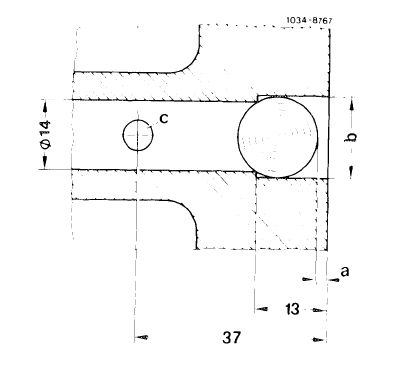

1 Thoroughly clean ball seat and bore in main oil duct.

2 Coat up on self-made knocking-in mandrel with grease and place steel ball into cup.

|

|

|||

|

|

||||

|

103-13 405

|

||||

|

|

||||

|

Material: C 45

|

|

|||

|

|

||||

|

3 Position steel ball with knocking-in mandrel and knock-in up to stop on mandrel.

|

|

|||

|

|

||||

|

If the mandrel has no stop, do not exceed dimension a = max. 3 mm to prevent cracking of crankcase.

|

|

|||

|

a = max. 3 mm

b= dia. 14.75 to 14.86 mm

c = oil ducts to crankshaft bearing

|

||||

|

01.2-130/4 F3

|

||||

|

|

||||

|

|

|||

|

4 Mount all parts taken off or removed.

5 Run engine warm and check for leaks.

Note: If oil flows out as the result of a leaking ball seat, knock-out respective steel ball and close main oil duct with a closing plug after cutting the required threads into duct.

|

|||

|

|

|||

|

Closing main oil duct with closing plug

|

|||

|

|

|||

|

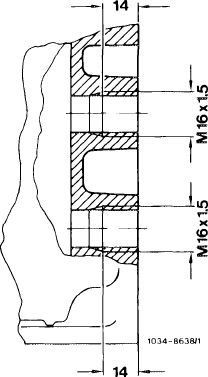

1 Cut threads M 16 x 1.5 mm approx. 14 mm deep into respective main oil duct.

2 Carefully clean main oil duct.

|

|

||

|

3 Screw closing plug M 16 x 1.5 mm DIN 908, part no. 000 908 016 001 with aluminum sealing ring A 16 x 22 mm DIN 7603 – AL, part no. 007 603 016 102, and tighten to 40 Nm.

|

|||

|

|

|||

|

01.2-130/5 F3

|

|||

|

|

|||