Installation and centering of intermediate flange

|

|

||||||||||||||||||||||||||||||||||

|

01—220 Installation and centering of intermediate flange

|

||||||||||||||||||||||||||||||||||

|

|

||||||||||||||||||||||||||||||||||

|

Data

|

||||||||||||||||||||||||||||||||||

|

|

||||||||||||||||||||||||||||||||||

|

Radial runout of intermediate flange

|

max. 0.10

|

|||||||||||||||||||||||||||||||||

|

|

||||||||||||||||||||||||||||||||||

|

Permissible axial runout of intermediate flange

when mounted in crankshaft bearing basic bore during

one full turn.

|

0.10

|

|||||||||||||||||||||||||||||||||

|

|

||||||||||||||||||||||||||||||||||

|

Tightening torques

|

Nm

|

|||||||||||||||||||||||||||||||||

|

|

||||||||||||||||||||||||||||||||||

|

Intermediate flange mounting bolts

|

65

|

|||||||||||||||||||||||||||||||||

|

|

||||||||||||||||||||||||||||||||||

|

Drive plate and flywheel expansion bolt

|

Torque pressure

|

40

|

||||||||||||||||||||||||||||||||

|

|

||||||||||||||||||||||||||||||||||

|

Torque angle

|

90-100°

|

|||||||||||||||||||||||||||||||||

|

|

||||||||||||||||||||||||||||||||||

|

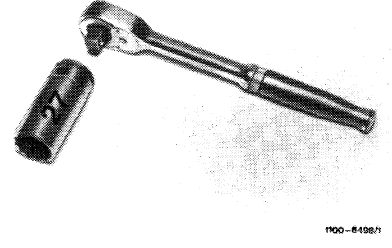

Special tool

|

||||||||||||||||||||||||||||||||||

|

|

||||||||||||||||||||||||||||||||||

|

||||||||||||||||||||||||||||||||||

|

|

||||||||||||||||||||||||||||||||||

|

Dial gage holder (two required)

|

121 589 00 21 00

|

|||||||||||||||||||||||||||||||||

|

|

||||||||||||||||||||||||||||||||||

|

||||||||||||||||||||||||||||||||||

|

|

||||||||||||||||||||||||||||||||||

|

Note

|

||||||||||||||||||||||||||||||||||

|

|

||||||||||||||||||||||||||||||||||

|

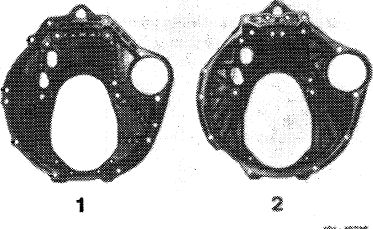

A replaced intermediate flange must be centered. The automatic transmission W4A040 requires the intermediate flange (1) with fitted pin and all-around centering system, which can be used as a replacement for the formerly used intermediate flange (2) with all-around centering system.

|

|

|||||||||||||||||||||||||||||||||

|

1 Modified intermediate flange 110 011 15 45

2 Former intermediate flange 115 011 11 45

|

||||||||||||||||||||||||||||||||||

|

|

||||||||||||||||||||||||||||||||||

|

01.2-220/1 F3

|

||||||||||||||||||||||||||||||||||

|

|

||||||||||||||||||||||||||||||||||

|

|

|||||

|

Series installation of intermediate flange

110 011 15 45 starting end of november 1979

Starting engine end no. Starting chassis end no.

|

|||||

|

|

|||||

|

110 923

|

~1 °-°14

|

123.030-028 448

|

|||

|

|

|||||

|

12-017 710 123.050-003 543

|

|||||

|

|

|||||

|

110.984 -10-021092 -12-070 620

|

123.033-067 904 123.053-018 127

|

||||

|

|

|||||

|

110.922

|

-10-040 775

|

||||

|

|

|||||

|

-12-067 894 110 932 -10-010 365 -12-002 796

|

116.020-121 410

|

||||

|

|

|||||

|

110.985 ~10-°14 287 116.024/025-154 967 12-073 060

|

|||||

|

|

|||||

|

110.986

|

-10-003 392 107.042-007 301 -12-007 701 107.022-007 921

|

||||

|

|

|||||

|

Installing and centering

|

|||||

|

|

|||||

|

1 Place intermediate flange over dowel pins in crankcase.

2 Tighten the four mounting bolts slightly.

|

|

||||

|

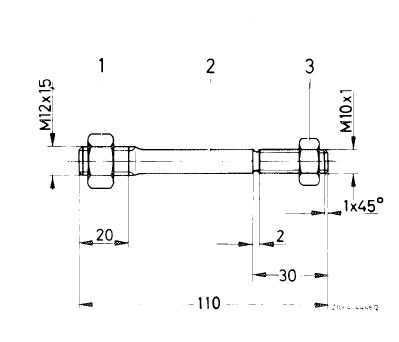

3 Screw threaded bolt (self-made) into crankshaft and counterlock with hex nut.

|

|||||

|

1 Hex nut M 12 x 1.5

2 Threaded bolt 10 mm dia

3 Hex nut M 10 x 1

|

|||||

|

|

|||||

|

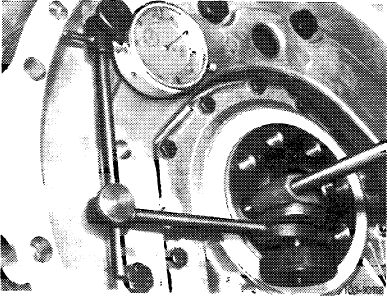

4 Attach dial gauge holder with dial gauge to threaded bolt.

5 Position feeler pin at fitting point of centering surface. Set dial gauge to 0.

|

|

||||

|

|

|||||

|

01.2-220/2 F3

|

|||||

|

|

|||||

|

|

|||

|

6 Rotate crankshaft for one full turn by means of tool combination. Vertical runout should not exceed max 0.10 mm.

Note: When rotating crankshaft, make sure that the feeler pin of the dial gauge is not getting stuck.

|

|

||

|

|

|||

|

7 Correct vertical runout by light blows against intermediate flange.

8 Tighten fastening screws.

Note: If the vertical runout exceeds 0.10 mm, remove intermediate flange.

9 Increase diameter of both fitted bores in intermediate flange to 12.1 mm.

10 Repeat item 1-8.

|

|||

|

|

|||

|

01.2-220/3 F3

|

|||

|

|

|||