Renewing ring gear of flywheel

|

|

|||||||||||||||||||||||||||||||||||

|

03—430 Renewing ring gear of flywheel

|

|||||||||||||||||||||||||||||||||||

|

|

|||||||||||||||||||||||||||||||||||

|

|||||||||||||||||||||||||||||||||||

|

|

|||||||||||||||||||||||||||||||||||

|

Temperature measuring chalk

|

e.g. from AW Faber-Castell D-8504 Stein bei Niirnberg color no. 2815/220 (white) Thermochrom

|

||||||||||||||||||||||||||||||||||

|

|

|||||||||||||||||||||||||||||||||||

|

Note

|

|||||||||||||||||||||||||||||||||||

|

|

|||||||||||||||||||||||||||||||||||

|

The ring gear is hardened. To protect hardness, the temperature for hardening ring gear should not exceed 220 °C at any point. This can be done reliably only by means of a hot plate or a heating oven.

An open flame may be used as an exception only. The flame should touch only the inside of the ring gear.

Following renewal of a ring gear, the flywheel need not be balanced.

|

|||||||||||||||||||||||||||||||||||

|

|

|||||||||||||||||||||||||||||||||||

|

Renewal

|

|||||||||||||||||||||||||||||||||||

|

|

|||||||||||||||||||||||||||||||||||

|

1 Center drill old ring gear and break up with a chisel or heat quickly and immediately remove.

2 Clean mounting surface of ring gear on flywheel.

3 Uniformly heat new ring gear on a hot plate or in a heating oven.

For this purpose, use temperature measuring chalk in accordance with instructions whenever possible.

|

|||||||||||||||||||||||||||||||||||

|

|

|||||||||||||||||||||||||||||||||||

|

03.8-430/1

|

|||||||||||||||||||||||||||||||||||

|

|

|||||||||||||||||||||||||||||||||||

|

|

|||

|

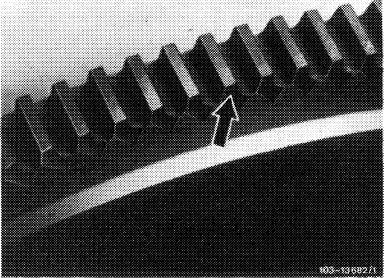

4 Mount heated ring gear immediately on flywheel.

Attention!

The tooth chamfer (arrow) should face starter motor.

As a spare part, ring gears are available with chamfered teeth only.

|

|

||

|

|

|||

|

03.8-430/2 F 2

|

|||

|

|

|||