Removal and installation of flywheel and driven plate

|

|

||||||||||||||||||||||||||||||||||||||||

|

03—410 Removal and installation of flywheel and driven plate

|

||||||||||||||||||||||||||||||||||||||||

|

|

||||||||||||||||||||||||||||||||||||||||

|

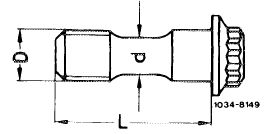

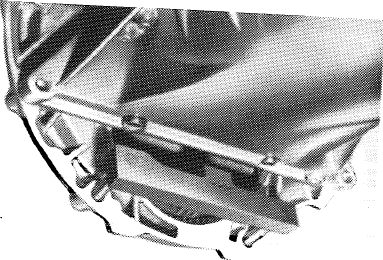

Necked-down screws

|

||||||||||||||||||||||||||||||||||||||||

|

|

||||||||||||||||||||||||||||||||||||||||

|

Part no.

|

110 990 04 19

|

|||||||||||||||||||||||||||||||||||||||

|

|

||||||||||||||||||||||||||||||||||||||||

|

Thread dia. D

|

M 10x 1

|

|

||||||||||||||||||||||||||||||||||||||

|

when new

|

7.7-0.2

|

|||||||||||||||||||||||||||||||||||||||

|

Necked-down stem dia. d

|

minimum dia. 7.3

|

|||||||||||||||||||||||||||||||||||||||

|

|

||||||||||||||||||||||||||||||||||||||||

|

||||||||||||||||||||||||||||||||||||||||

|

|

||||||||||||||||||||||||||||||||||||||||

|

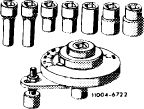

Angle of rotation tool

|

|

116 589 01 13 00

|

||||||||||||||||||||||||||||||||||||||

|

|

||||||||||||||||||||||||||||||||||||||||

|

Detent

|

|

110 589 00 40 00

|

||||||||||||||||||||||||||||||||||||||

|

|

||||||||||||||||||||||||||||||||||||||||

|

Note

|

|

|||||||||||||||||||||||||||||||||||||||

|

If a new flywheel is installed, set new wheel to balancing condition of removed wheel (03—440).

|

||||||||||||||||||||||||||||||||||||||||

|

|

||||||||||||||||||||||||||||||||||||||||

|

03.8-410/1 F2

|

||||||||||||||||||||||||||||||||||||||||

|

|

||||||||||||||||||||||||||||||||||||||||

|

|

|||||||||

|

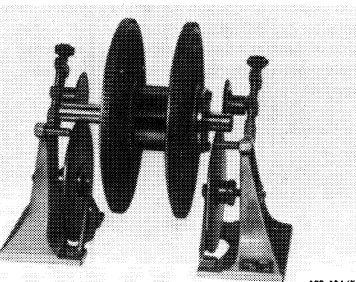

” “vwheel with

|

°f

|

|

|||||||

|

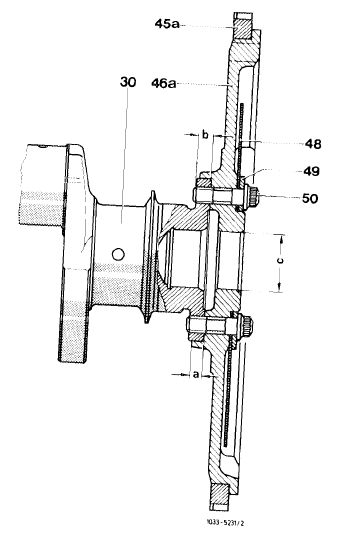

Engine 110: dimension a = 4.5

|

mm

|

||||||||

|

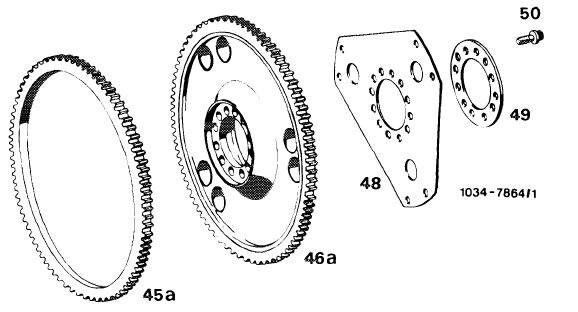

Layout flywheel and driven plate 30 Crankshaft

|

|||||||||

|

45a Ring gear 46a Flywheel

|

b J° mm C 5 mm dia–

|

||||||||

|

48 Driven plate

49 Spacing washer

50 Necked-down screw

|

|||||||||

|

|

|||||||||

|

Removal

|

|||||||||

|

|

|||||||||

|

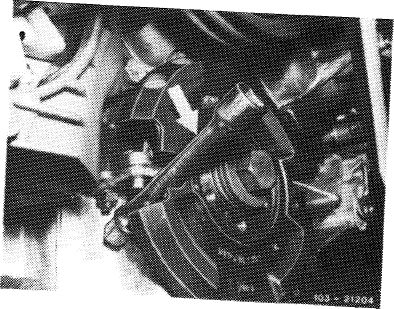

1 Remove transmission.

2 On models 116.120 and 123 with automatic trans miRslrtn 722120 <W4B 025), position

|

|

||||||||

|

|

|||||||||

|

one of (arrow)3

|

recesses on balancing disc for counter-

|

|

|||||||

|

|

Crankcase

|

|

|||||||

|

03.8-410/2 F 2

|

|||||||||

|

|

|||||||||

|

|

||||

|

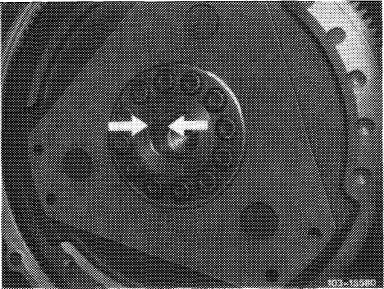

3 Loosen necked-down screws. Remove flywheel, driven plate and spacing washer.

Note: The flywheel and crankshaft are identified by a mark (arrows).

|

|

|||

|

|

||||

|

Installation

|

||||

|

|

||||

|

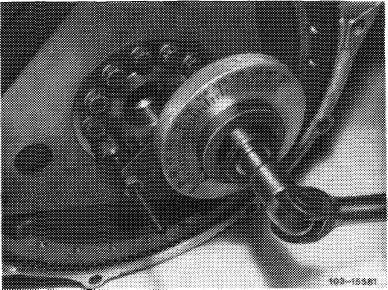

4 Measure necked-down stem dia. “d” of necked-down screws.

If the minimum dia. has been attained, replace necked-down screws.

5 Position flywheel, driven plate and spacing washer on crankshaft journal in such a manner that the marks are in alignment.

|

||||

|

|

||||

|

6 Lubricate necked-down screws, screw-in and tighten to 30-40 Nm.

7 Tighten to angle of rotation torque of 90—100° by means of angle of rotation tool.

|

|

|||

|

|

||||

|

Flywheel and driven plate

|

|

|||

|

45a Ring gear

46a Flywheel

48 Driven plate

49 Spacing washer

50 12 necked-down screws

|

||||

|

|

||||

|

03.8-410/3 F2

|

||||

|

|

||||