Measuring, boring and honing cylinder bores

|

|

||||||||||||||||||||||||||||

|

01—110 Measuring, boring and honing cylinder bores

|

||||||||||||||||||||||||||||

|

|

||||||||||||||||||||||||||||

|

Coordination piston — cylinder

|

||||||||||||||||||||||||||||

|

|

||||||||||||||||||||||||||||

|

||||||||||||||||||||||||||||

|

|

||||||||||||||||||||||||||||

|

Cylinder bore

|

||||||||||||||||||||||||||||

|

|

||||||||||||||||||||||||||||

|

Max. wear limit in forward or transverse direction

|

0.10

|

|||||||||||||||||||||||||||

|

|

||||||||||||||||||||||||||||

|

when new

|

0.014

|

|||||||||||||||||||||||||||

|

|

||||||||||||||||||||||||||||

|

Permissible out-of-true and conicity

|

||||||||||||||||||||||||||||

|

|

||||||||||||||||||||||||||||

|

wear limit

|

0.05

|

|||||||||||||||||||||||||||

|

|

||||||||||||||||||||||||||||

|

Permissible deviation vertically in relation to crankshaft center line, with reference to cylinder height

|

0.05

|

|||||||||||||||||||||||||||

|

|

||||||||||||||||||||||||||||

|

Permissible roughness

|

0.002-0.004

|

|||||||||||||||||||||||||||

|

|

||||||||||||||||||||||||||||

|

Permissible waviness

|

50 % of roughness

|

|||||||||||||||||||||||||||

|

|

||||||||||||||||||||||||||||

|

Honing angle

|

25C

|

|||||||||||||||||||||||||||

|

|

||||||||||||||||||||||||||||

|

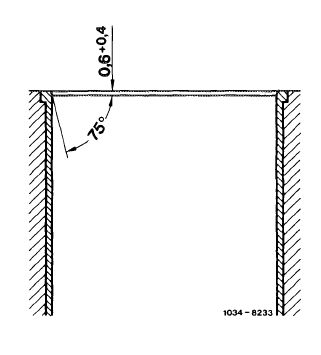

Chamfer of cylinder bores

|

refer to Fig.

|

|||||||||||||||||||||||||||

|

|

||||||||||||||||||||||||||||

|

1 These engines have no repair steps.

|

||||||||||||||||||||||||||||

|

|

||||||||||||||||||||||||||||

|

Note

|

||||||||||||||||||||||||||||

|

|

||||||||||||||||||||||||||||

|

In addition of a visual checkup, in particular in the event of complaints about “high oil consumption” measuring of cylinder bores is unavoidable.

|

||||||||||||||||||||||||||||

|

|

||||||||||||||||||||||||||||

|

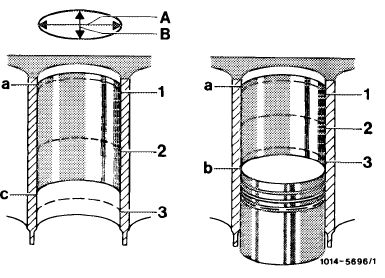

For this purpose, measure the clean cylinder bores with internal measuring instrument at measuring points, 1, 2 and 3 in longitudinal direction A (piston pin center line) and in transverse direction B.

With piston installed, the measuring point 3 is barely above piston, at BDC.

|

|

|||||||||||||||||||||||||||

|

a Upper reversing point of 1st piston ring

b BDC of piston

c Lower reversing point of oil scraper ring

|

||||||||||||||||||||||||||||

|

|

||||||||||||||||||||||||||||

|

01.8-110/1 F2

|

||||||||||||||||||||||||||||

|

|

||||||||||||||||||||||||||||

|

|

|||

|

Chamfer cylinder bores after boring.

For honing, the material allowance should not exceed 0.03 mm.

|

|

||

|

|

|||

|

01.8-110/2 F2

|

|||

|

|

|||