Renewing, boring and honing cylinder liners

|

|

||||||||||||||||||||||||||||||||||||||||||||||

|

01—115 Renewing, boring and honing cylinder liners

|

||||||||||||||||||||||||||||||||||||||||||||||

|

|

||||||||||||||||||||||||||||||||||||||||||||||

|

Coordination piston — cylinder

|

||||||||||||||||||||||||||||||||||||||||||||||

|

|

||||||||||||||||||||||||||||||||||||||||||||||

|

||||||||||||||||||||||||||||||||||||||||||||||

|

|

||||||||||||||||||||||||||||||||||||||||||||||

|

Cylinder crankcase

|

||||||||||||||||||||||||||||||||||||||||||||||

|

|

||||||||||||||||||||||||||||||||||||||||||||||

|

||||||||||||||||||||||||||||||||||||||||||||||

|

|

||||||||||||||||||||||||||||||||||||||||||||||

|

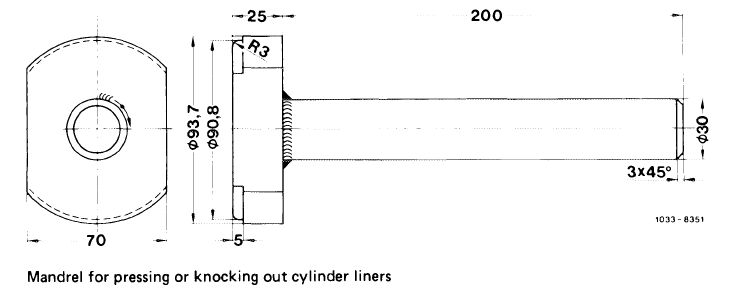

Self-made tool

|

||||||||||||||||||||||||||||||||||||||||||||||

|

|

||||||||||||||||||||||||||||||||||||||||||||||

|

||||||||||||||||||||||||||||||||||||||||||||||

|

|

||||||||||||||||||||||||||||||||||||||||||||||

|

01.8-115/1 F2

|

||||||||||||||||||||||||||||||||||||||||||||||

|

|

||||||||||||||||||||||||||||||||||||||||||||||

|

|

|||

|

Note

Always install approved cylinder liners only (refer to spare parts data).

Owing to different manufacturers, the cylinder liners are identified with notches at lower edge.

1 notch = Teves; 2 notches = Pleuco;

3 notches = Wizemann; 4 notches = Brico

|

|||

|

|

|||

|

Renewal

|

|||

|

|

|||

|

1 Press out cylinder liners with self-made mandrel and a press or knock out with a hammer.

2 Thoroughly clean basic bore.

|

|

||

|

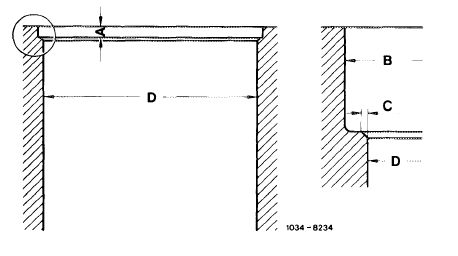

A = 4.3-4.6 mm

B = 96.02-96.08 mm

C = 0.25-0.35 mm

D = 94.000-94.035 mm

|

|||

|

|

|||

|

3 Measure basic bore (D) in cylinder crankcase.

If the out-of-true condition exceeds 0.1 mm, do not use cylinder crankcase any longer.

|

|||

|

|

|||

|

4 Position new cylinder liners. Place steel plate of pertinent size on liner flange and press-in liner with a press or knock in with a hammer.

After pressing or knocking in cylinder liner, leave for another approx. 7 seconds under press (setting pressure) or add a few setting blows with hammer.

|

|||

|

|

|||

|

01.8-115/2 F2

|

|||

|

|

|||

|

|

|||

|

5 Mill or grind off projecting liner flange. Remove as little as possible from cylinder crankcase parting surface. Guide milling cutter or grinding wheel centrally over cylinder bores.

6 Enlarge cylinder liner bores in two steps. For honing, leave an allowance of 0.03 mm in bores.

|

|

||

|

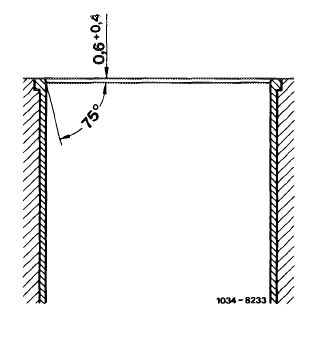

7 Chamfer cylinder liners.

8 Hone cylinder bores.

9 Measure cylinder bores and select pertinent pistons (02-316).

|

|||

|

|

|||

|

01.8-115/3 F2

|

|||

|

|

|||