Installation and centering of intermediate flange

|

|

||||

|

01—220 Installation and centering of intermediate flange

|

||||

|

|

||||

|

Data

|

||||

|

|

||||

|

Vertical runout of intermediate flange

|

max. 0.10

|

|||

|

|

||||

|

Tightening torques

|

Nm

|

|||

|

|

||||

|

Fastening screws for intermediate flange

|

50

|

|||

|

|

||||

|

initial torque

|

40

|

|||

|

|

||||

|

Necked-down screw for driven plate and flywheel

|

||||

|

|

||||

|

angle of rotation torque 90—100°

|

||||

|

|

||||

|

Special tools

|

||||

|

|

||||

|

Dial gauge holder (2 each required)

|

|

363 589 02 21 00

|

||

|

|

||||

|

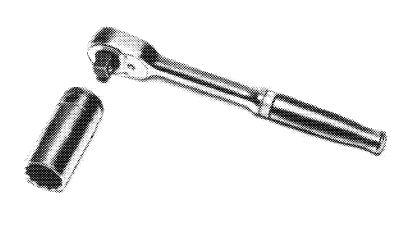

Socket 27 mm, 1/2″ square for rotating engine

|

|

001 589 65 09 00

|

||

|

|

||||

|

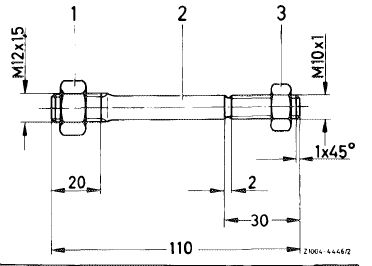

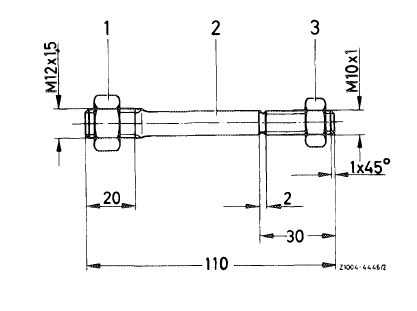

Self-made tool

|

||||

|

|

||||

|

Threaded bolt

|

|

|||

|

|

||||

|

01.8-220/1 F2

|

||||

|

|

||||

|

|

||||

|

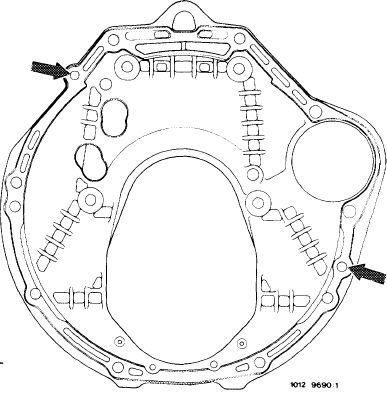

The intermediate flange is provided with two additional bores for centering the fitted pins of automatic transmission 722.303 (W 4 A 040).

This intermediate flange is also installed on engines with automatic transmission 722.120 (W 4 B 025). Part no. 615 011 02 45.

|

|

|||

|

Start of series: February 1980

|

||||

|

Model

|

Engine end no. _, Engine Chassis end no.

|

|||

|

|

||||

|

116.120 617.950 022432 022082

123 617.952 start of series

126.120 617.951 start of series

|

||||

|

|

||||

|

Installation and centering

|

|

|||

|

1 Insert intermediate flange into fitted pins on cylinder crankcase.

2 Slightly tighten the four fastening screws.

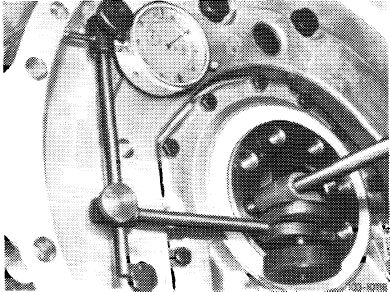

3 Screw threaded bolt (self-made) into crankshaft and counterlock with hex. nut.

|

||||

|

|

||||

|

4 Attach dial gauge holder with dial gauge to threaded bolt.

5 Position feeler pin against OD of round center.

|

|

|||

|

Shown on engine 116

|

||||

|

|

||||

|

01.8-220/2 F2

|

||||

|

|

||||

|

|

|||

|

6 Turn crankshaft with tool combination and measure vertical runout. Vertical runout should not exceed max. 0.10 mm.

Note: When turning crankshaft, make sure that feeler pin of dial gauge is not getting stuck.

7 Correct vertical runout by means of light blows against intermediate flange.

|

|

||

|

|

|||

|

R10Q/6498

|

|||

|

|

|||

|

8 Tighten fastening screws.

Note: If the vertical runout exceeds 0.10 mm, remove intermediate flange.

9 Drill both fitted bores in intermediate flange to 12.1 mm.

10 Repeat item 1—8.

|

|||

|

|

|||

|

01.8-220/3 F2

|

|||

|

|

|||