Checking injection timing (begin of delivery) (position indicator RIV method)

|

|

||||||||||||||||||||||||||||||||||||

|

07.1-111 Checking injection timing (begin of delivery) (position indicator RIV method)

|

||||||||||||||||||||||||||||||||||||

|

|

||||||||||||||||||||||||||||||||||||

|

Job no. of flat rates or standard texts and flat rates data 07—8240.

|

||||||||||||||||||||||||||||||||||||

|

|

||||||||||||||||||||||||||||||||||||

|

||||||||||||||||||||||||||||||||||||

|

|

||||||||||||||||||||||||||||||||||||

|

Position indicator

|

|

617 589 08 21 00

|

||||||||||||||||||||||||||||||||||

|

|

||||||||||||||||||||||||||||||||||||

|

Drive square 1/2″, 80 mm long for rotating engine

|

loot o o’oo’o1!

11004-10282

|

617 589 00 16 00

|

||||||||||||||||||||||||||||||||||

|

|

||||||||||||||||||||||||||||||||||||

|

Checking

|

|

|||||||||||||||||||||||||||||||||||

|

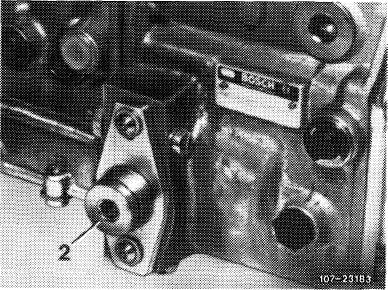

1 Remove closing plug (2).

Attention!

When removing closing plug approx. 0.2 I engine oil will flow out. Collect oil.

|

||||||||||||||||||||||||||||||||||||

|

|

||||||||||||||||||||||||||||||||||||

|

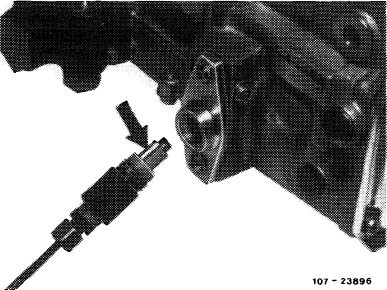

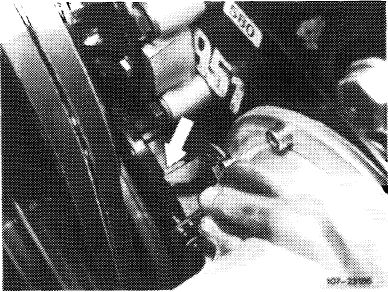

2 Slip position transmitter into regulator housing. Make sure that the guide pin of position indicator (arrow) is pointing upward. Tighten coupling nut manually.

|

|

|||||||||||||||||||||||||||||||||||

|

|

||||||||||||||||||||||||||||||||||||

|

07.1.8-111/1 F3

|

||||||||||||||||||||||||||||||||||||

|

|

||||||||||||||||||||||||||||||||||||

|

|

|||

|

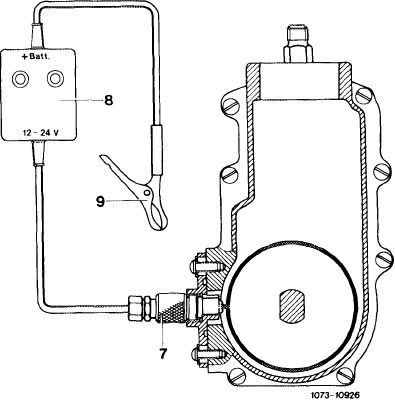

3 Connect indicating unit according to wiring diagram.

|

|

||

|

7 Position indicator

8 Indicating unit

9 Battery terminal (battery +)

|

|||

|

|

|||

|

4 Rotate engine manually (in direction of rotation only) until lamp “A” lights up. Carefully continue rotating engine until both lamps are lighting up (“A and B”). In this position, read begin of delivery on graduated scale.

Rl-value: -15° after TDC

If only lamp “B” lights up, repeat checkup.

|

|

||

|

|

|||

|

5 Remove position indicator, screw in closing plug.

6 Perform leak test with engine running. Check engine oil level or correct, if required.

|

|||

|

|

|||

|

07.1.8-111/2 F3

|

|||

|

|

|||