Checking compression pressure

|

|

||||||||||||||||||||||||||||||||

|

01—010 Checking compression pressure

|

||||||||||||||||||||||||||||||||

|

|

||||||||||||||||||||||||||||||||

|

Test values for engine at operating temperature in bar gauge pressure (atii)

|

||||||||||||||||||||||||||||||||

|

|

||||||||||||||||||||||||||||||||

|

Normal compression pressure

|

24-30

|

|||||||||||||||||||||||||||||||

|

|

||||||||||||||||||||||||||||||||

|

Minimum compression pressure

|

approx. 15

|

|||||||||||||||||||||||||||||||

|

|

||||||||||||||||||||||||||||||||

|

Permissible difference between the individual cylinders

|

max. 3

|

|||||||||||||||||||||||||||||||

|

|

||||||||||||||||||||||||||||||||

|

||||||||||||||||||||||||||||||||

|

|

||||||||||||||||||||||||||||||||

|

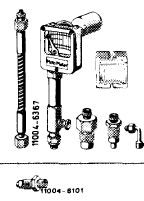

Compression pressure recorder with accessories

|

|

001 589 47 21 00

|

||||||||||||||||||||||||||||||

|

Screw-in fitting for heating plug bore

|

617 589 03 21 00

|

|||||||||||||||||||||||||||||||

|

|

||||||||||||||||||||||||||||||||

|

Contact handle for rotating engine (Component of compression pressure recorder 001 589 46 21 00)

|

|

001 589 46 21 08

|

||||||||||||||||||||||||||||||

|

|

||||||||||||||||||||||||||||||||

|

Note

|

||||||||||||||||||||||||||||||||

|

|

||||||||||||||||||||||||||||||||

|

Measure compression pressure at 80 °C coolant temperature. The compression pressure can be tested via heating plug bore or via prechambers. When pressure is below minimum compression pressure, check cylinders for leaks (01—015).

|

||||||||||||||||||||||||||||||||

|

|

||||||||||||||||||||||||||||||||

|

01.8-010/1 F2

|

||||||||||||||||||||||||||||||||

|

|

||||||||||||||||||||||||||||||||

|

|

|||

|

Checking

|

|

||

|

1 Remove heating plugs or injection nozzles.

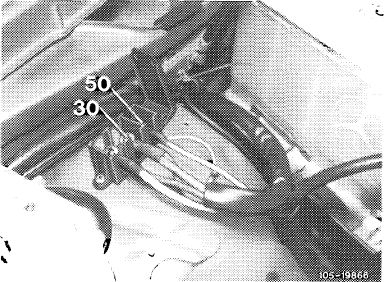

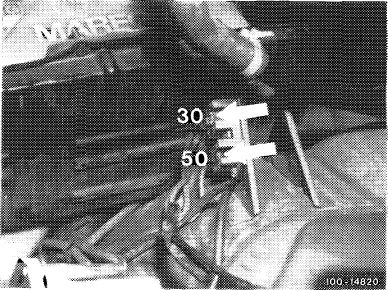

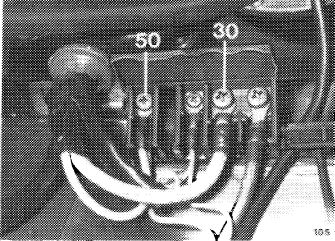

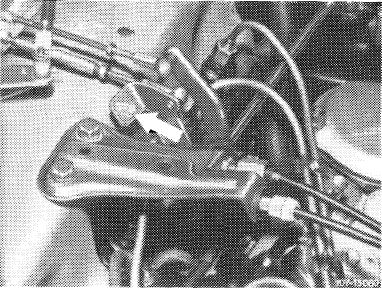

2 Connect contact handle under battery to cable connector terminal 30 and 50.

|

|||

|

Model 116.120

|

|||

|

|

|||

|

The cable connector is attached at the following points:

Model 116.120: Under battery. Model 123 : On wheelhouse, right. Model 126.120: On frame side member

|

\

|

||

|

Model 123

|

|||

|

|

|||

|

Model 126.120

|

|

||

|

|

|||

|

3 Rotate engine several times at transmission idle position, so that residue and soot are thrown out.

Attention!

For the above purpose, push shutoff lever (stop) in direction of engine so that the injection pump is not injecting.

|

|

||

|

|

|||

|

01.8-010/2 F2

|

|||

|

|

|||

|

|

|||

|

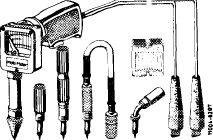

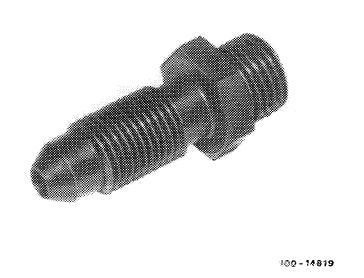

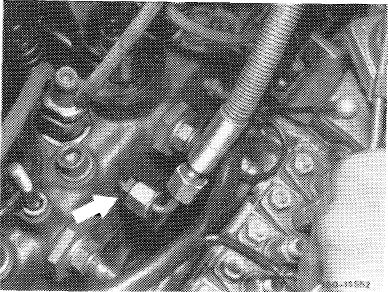

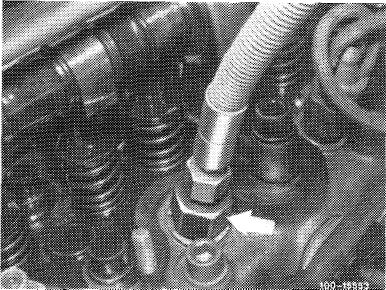

4 Enter screw fitting into glow plug bore or

adaptor (component of compression pressure recorder)

into prechamber.

Connect compression pressure recorder.

|

|

||

|

Screw fitting

|

|||

|

|

|||

|

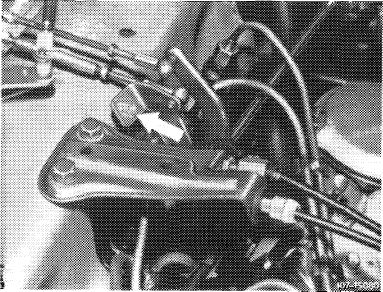

Compression pressure recorder, connected to glow plug bore

|

|

||

|

|

|||

|

Compression pressure recorder, connected to prechamber

|

|

||

|

|

|||

|

5 Rotate engine 8 revolutions for testing.

Attention!

For the above purpose, push shutoff lever (stop) in direction of engine so that the injection pump is not injecting.

6 Insert new nozzle reeds prior to installation of injection nozzle.

|

|

||

|

|

|||

|

01.8-010/3 F2

|

|||

|

|

|||

Poprzedni

Technical data

Nowsze