Checking and reconditioning of crankshaft

|

|

|||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|

03—318 Checking and reconditioning of crankshaft

|

|||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|

|

|||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|

Data

|

|||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|

|

|||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|

|||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|

|

|||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|

Permissible out-of-round of crankshaft journals and crankpins

|

0.005

|

||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|

|

|||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|

Permissible conicity of crankshaft journals and crankpins

|

0.01

|

||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|

|

|||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|

Permissible radial runout of flywheel flange

|

0.02

|

||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|

|

|||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|

Permissible axial runout of fitted bearing

|

0.02

|

||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|

|

|||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|

on crankshaft bearing journals

|

2.5 to 3.0

|

||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|

|

|||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|

Fillets

|

|||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|

|

|||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|

on crankpins

|

3.0 to 3.5

|

||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|

|

|||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|

Permissible radial runout of crankshaft journals when mounted on outer journals

|

journal II, V

|

0.16

|

|||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|

journal III, IV

|

0.25

|

||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|

|

|||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|

Scleroscope hardness of crankshaft journals and crankpins

|

55-74

|

||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|

|

|||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|

Permissible unbalance of crankshaft

|

15 cmg

|

||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|

|

|||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|

03.8-318/1

|

|||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|

|

|||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|

|

||

|

Note

|

||

|

|

||

|

The bearing journals of crankshaft are not inductance hardened similar to other engines, but are hardened in a nitride bath.

Contrary to inductance hardened crankshaft, a bath-nitrided crankshaft is hardened at its entire surface.

|

||

|

|

||

|

Conventional hardness tester (hardness drop tester) provides no information concerning proper hardness (depth of connecting layer) for crankshafts hardened in a nitride bath. No hardness test according to the above method is therefore required.

|

||

|

|

||

|

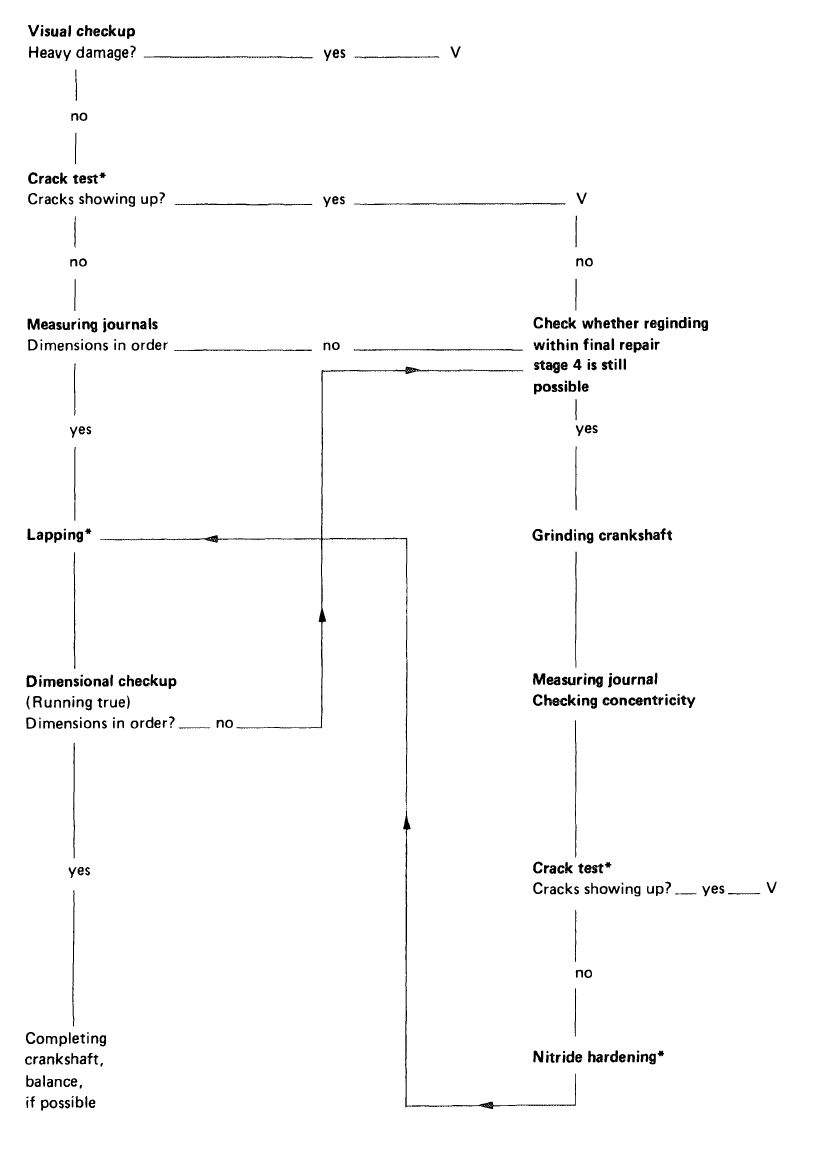

When testing and reconditioning crankshafts, proceed in sequence of diagram below.

|

||

|

|

||

|

Diagram

|

||

|

|

||

|

* Refer to section “Explanations Concerning Diagram” V = scrap.

|

||

|

|

||

|

03.8-318/2

|

||

|

|

||

|

|

||

|

||

|

|

||

|

03.8-318/3

|

||

|

|

||

|

|

||

|

Explanations concerning diagram

|

||

|

|

||

|

Crack test

|

||

|

|

||

|

Clean crankshaft. Bearing journals should be free of oil and grease.

Magnetize crankshaft and apply fluorescent powder (fluxing).

A color penetration test (immersion in bath or using spray can) may also be applied.

Aid: Paint or fluorescent powder Cleaning agent Developer

|

||

|

|

||

|

Hardening

Crankshaft must be nitride-hardened in a salt bath.

Attention!

Prior to nitriding, close all threaded bores in crankshaft.

|

||

|

|

||

|

Hardened threads will loose in strength and may therefore break out when tightening screws.

Screw-in necked-down screws on flywheel flange.

Screw-in a hollow center screw M 18 x 1.5 x 45 at front on crankshaft.

|

||

|

|

||

|

Center screw is bored hollow to prevent a chemical reaction in salt bath caused by the air which might be enclosed behind screw.

Duration and bath temperature are shown in nitriding specifications included upon delivery of nitriding equipment.

To avoid distorsion of crankshaft, suspend crankshaft vertically into nitriding bath.

|

||

|

|

||

|

03.8-318/4 F2

|

||

|

|

||

Poprzedni

Removal and installation of pistons

Nowsze