Grinding camshaft bearing journals

|

|

|||||||||||||||||||||||||||||||||||||||||

|

05—225 Grinding camshaft bearing journals

|

|||||||||||||||||||||||||||||||||||||||||

|

|

|||||||||||||||||||||||||||||||||||||||||

|

Data

|

|||||||||||||||||||||||||||||||||||||||||

|

|

|||||||||||||||||||||||||||||||||||||||||

|

Mean roughness of camshaft bearing journal

|

0.005

|

||||||||||||||||||||||||||||||||||||||||

|

|

|||||||||||||||||||||||||||||||||||||||||

|

Deviation of camshaft bearing journal from true when mounted at camshaft sprocket seat and rear camshaft bearing journal

|

0.030

|

||||||||||||||||||||||||||||||||||||||||

|

|

|||||||||||||||||||||||||||||||||||||||||

|

Deviation of camshaft bearing journal from true

|

0.010

|

||||||||||||||||||||||||||||||||||||||||

|

|

|||||||||||||||||||||||||||||||||||||||||

|

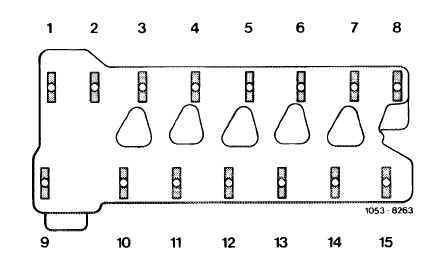

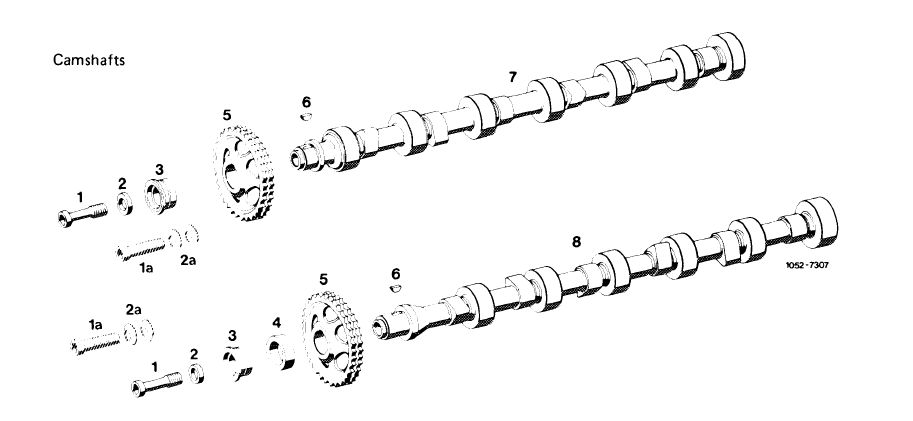

Bearing points (fig., refer to note)

|

1,9

|

3,10,11 4,5,12,13 6,7,14,15 8

|

|||||||||||||||||||||||||||||||||||||||

|

|

|||||||||||||||||||||||||||||||||||||||||

|

bearing dia 38.016 50.066 50.016 51.519 53.019 54.019

38.000 50.050 50.000 51.500 53.000 54.000

|

|||||||||||||||||||||||||||||||||||||||||

|

|

|||||||||||||||||||||||||||||||||||||||||

|

Standard dimension

|

|||||||||||||||||||||||||||||||||||||||||

|

|

|||||||||||||||||||||||||||||||||||||||||

|

journal dia.

|

23.993 49.950 49.950 51.440 52.940 53.940

|

||||||||||||||||||||||||||||||||||||||||

|

23.980

|

49.934 49.934

|

51.421

|

52.921

|

53.921

|

|||||||||||||||||||||||||||||||||||||

|

|

|||||||||||||||||||||||||||||||||||||||||

|

Intermediate stage —0.1 mm (exchange engines)

|

bearing dia.

|

49.966 49.916 51.419 49.950 49.900 51.400

|

52.919 53.919 52.900 53.900

|

||||||||||||||||||||||||||||||||||||||

|

journal dia.

|

49.850 49.850 51.340 52.840 53.840 49.834 49.834 51.321 52.821 53.821

|

||||||||||||||||||||||||||||||||||||||||

|

|

|||||||||||||||||||||||||||||||||||||||||

|

1st repair stage -0.25 mm

|

bearing dia.

|

49.816 49.765 51.269 52.769 53.769 49.800 49.750 51.250 52.750 53.750

|

|||||||||||||||||||||||||||||||||||||||

|

|

|||||||||||||||||||||||||||||||||||||||||

|

journal dia.

|

49.700 49.684

|

49.700 49.684

|

51.190 51.171

|

52.690 52.671

|

53.690 53.671

|

||||||||||||||||||||||||||||||||||||

|

|

|||||||||||||||||||||||||||||||||||||||||

|

2nd repair stage —0.5 mm

|

bearing dia.

|

49.566 49.550

|

49.516 49.500

|

51.019 51.000

|

52.519 52.500

|

53.519 53.500

|

|||||||||||||||||||||||||||||||||||

|

journal dia.

|

49.450 49.450

|

50.940 52.440 53.440 50.921 52.421 53.421

|

|||||||||||||||||||||||||||||||||||||||

|

49.434

|

49.434

|

||||||||||||||||||||||||||||||||||||||||

|

|

|||||||||||||||||||||||||||||||||||||||||

|

Camshaft bearing play

|

radial

|

0.057 0.124

|

0.100 0.132

|

0.050 0.082

|

0.060 0.098

|

0.060 0.098

|

0.060 0.098

|

||||||||||||||||||||||||||||||||||

|

axial

|

0.050 0.120

|

||||||||||||||||||||||||||||||||||||||||

|

|

|||||||||||||||||||||||||||||||||||||||||

|

|||||||||||||||||||||||||||||||||||||||||

|

|

|||||||||||||||||||||||||||||||||||||||||

|

Dial gauge holder for camshaft axial play

|

|

136 589 04 21 00

|

|||||||||||||||||||||||||||||||||||||||

|

|

|||||||||||||||||||||||||||||||||||||||||

|

05.2-225/1 F3

|

|||||||||||||||||||||||||||||||||||||||||

|

|

|||||||||||||||||||||||||||||||||||||||||

|

|

|||

|

Note

|

|

||

|

For camshafts with reground bearing journals, camshaft housings with repair stages —0.25 mm and —0.50 mm are available.

The bearing journals are not hardened.

|

|||

|

|

|||

|

Some exchange engines are delivered with camshaft bearings in intermediate and repair sizes. This means that a standard camshaft cannot be installed in this camshaft housing, since the bearing journals are larger in diameter than the bearings.

Also refer to coordination camshaft housing and camshafts (01-471).

|

|||

|

|

|||

|

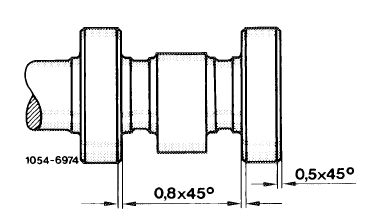

Chamfer bearing journals after grinding (see sketch for dimensions).

|

|

||

|

|

|||

|

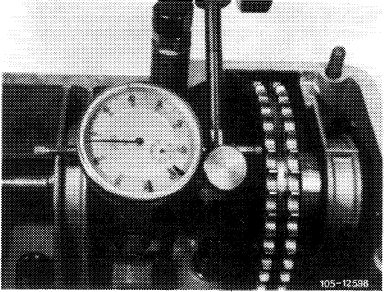

Checking axial play

|

|

||

|

1 Bolt dial gauge holder to camshaft housing.

|

|||

|

2 Clamp dial gauge with a preload of about 3 mm.

|

|||

|

3 Press back camshaft and set needle at 0.

|

|||

|

4 Press camshaft forward and read axial play.

|

|||

|

|

|||

|

05.2-225/2 F3

|

|||

|

|

|||

|

|

||||||||||||||||||||||||||||||||||||||||||||||||||||

|

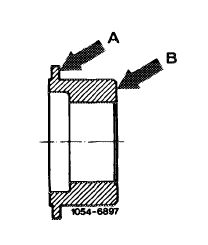

Note: If the end play is too small, grind spacing sleeve or driver at face B as required.

If the axial play is too large, the spacer or dog must be ground at collar A.

|

|

|||||||||||||||||||||||||||||||||||||||||||||||||||

|

|

||||||||||||||||||||||||||||||||||||||||||||||||||||

|

||||||||||||||||||||||||||||||||||||||||||||||||||||

|

|

||||||||||||||||||||||||||||||||||||||||||||||||||||

|

||||||||||||||||||||||||||||||||||||||||||||||||||||

|

|

||||||||||||||||||||||||||||||||||||||||||||||||||||

|

05.2-225/3 F3

|

||||||||||||||||||||||||||||||||||||||||||||||||||||

|

|

||||||||||||||||||||||||||||||||||||||||||||||||||||