Grinding camshaft bearing journals

|

|

|||||||||||||||||||||||||||||||

|

05—225 Grinding camshaft bearing journals

|

|||||||||||||||||||||||||||||||

|

|

|||||||||||||||||||||||||||||||

|

Data

|

|||||||||||||||||||||||||||||||

|

|

|||||||||||||||||||||||||||||||

|

Roughness of camshaft bearing journals

|

0.003

|

||||||||||||||||||||||||||||||

|

|

|||||||||||||||||||||||||||||||

|

Permissible runout of center bearing journals and camshaft sprocket seat when mounting camshaft at outer bearing journals

|

Camshaft code number1)

|

00

|

05,08

|

||||||||||||||||||||||||||||

|

|||||||||||||||||||||||||||||||

|

|

|||||||||||||||||||||||||||||||

|

Scleroscope hardness of cams

|

70-82

|

64-75

|

|||||||||||||||||||||||||||||

|

|

|||||||||||||||||||||||||||||||

|

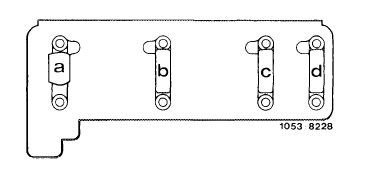

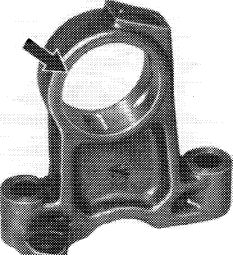

Bearing points (Fig.)

|

b, c and d

|

||||||||||||||||||||||||||||||

|

|

|||||||||||||||||||||||||||||||

|

Camshaft bearing dia.

|

35.00 35.02

|

46.50 46.52

|

49.00 49.02

|

||||||||||||||||||||||||||||

|

|

|||||||||||||||||||||||||||||||

|

Standard dimension

|

|||||||||||||||||||||||||||||||

|

|

|||||||||||||||||||||||||||||||

|

Journal dia.

|

34.95 34.93

|

46.45 46.43

|

48.95 48.93

|

||||||||||||||||||||||||||||

|

|

|||||||||||||||||||||||||||||||

|

Camshaft bearing dia. (color code grey)

|

34.90 34.92

|

46.40 46.42

|

48.90 48.92

|

||||||||||||||||||||||||||||

|

|

|||||||||||||||||||||||||||||||

|

Intermediate stage

|

|||||||||||||||||||||||||||||||

|

|

|||||||||||||||||||||||||||||||

|

Journal dia.

|

34.85 34.83

|

46.35 46.33

|

48.85 48.83

|

||||||||||||||||||||||||||||

|

|

|||||||||||||||||||||||||||||||

|

Camshaft bearing dia. (color code red)

|

34.75 34.77

|

46.25 46.27

|

48.75 48.77

|

||||||||||||||||||||||||||||

|

|

|||||||||||||||||||||||||||||||

|

Repair stage I

|

|||||||||||||||||||||||||||||||

|

|

|||||||||||||||||||||||||||||||

|

Journal dia.

|

34.70 34.68

|

46.20 46.18

|

48.70 48.68

|

||||||||||||||||||||||||||||

|

|

|||||||||||||||||||||||||||||||

|

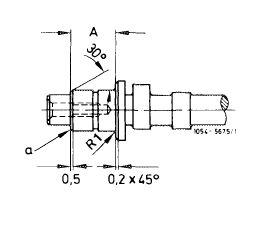

Width A of journal a (Fig.)

|

34.00 34.04

|

||||||||||||||||||||||||||||||

|

|

|||||||||||||||||||||||||||||||

|

radial

|

0.050-0.084

|

||||||||||||||||||||||||||||||

|

|

|||||||||||||||||||||||||||||||

|

Bearing play

|

|||||||||||||||||||||||||||||||

|

|

|||||||||||||||||||||||||||||||

|

axial

|

0.07-0.15

|

||||||||||||||||||||||||||||||

|

|

|||||||||||||||||||||||||||||||

|

‘) Code number is punched into rear end of camshaft. 2) Camshaft bearings and journal dia. on engine 617.95C

|

lodel year 1980 with increased output and engines 617.951/952.

|

||||||||||||||||||||||||||||||

|

|

|||||||||||||||||||||||||||||||

|

Special tool

|

|||||||||||||||||||||||||||||||

|

|

|||||||||||||||||||||||||||||||

|

Dial gage holder for end play of camshaft (2 each)

|

|

363 589 02 21 00

|

|||||||||||||||||||||||||||||

|

11OO4-W150

|

|||||||||||||||||||||||||||||||

|

|

|||||||||||||||||||||||||||||||

|

Conventional tool

|

|||||||||||||||||||||||||||||||

|

|

|||||||||||||||||||||||||||||||

|

Dial gage A 1 DIN 878

|

e.g. made by Mahr, D-7300 Esslingen Order No. 810

|

||||||||||||||||||||||||||||||

|

|

|||||||||||||||||||||||||||||||

|

05.8-225/1 F 2

|

|||||||||||||||||||||||||||||||

|

|

|||||||||||||||||||||||||||||||

|

|

|||

|

Note

In the event of repairs, regrind camshaft in accordance with available camshaft bearings.

Camshaft bearing journals are not hardened.

|

|

||

|

|

|||

|

If dimension A is exceeded when grinding 1st bearing journal, also regrind face a.

|

|

||

|

|

|||

|

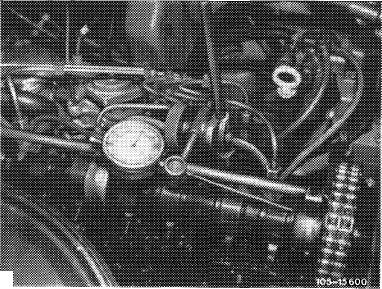

Measuring end play

|

\

|

||

|

1 Screw on dial gage holder with threaded sleeve at front left.

2 Position dial gage at approx. 3 mm preload against thrust flange of camshaft.

3 Push camshaft toward the rear and set large needle to zero.

|

|||

|

|

|||

|

4 Push camshaft forward and determine end play.

Note: If the end play is too low, touch up 1st camshaft bearing at its face surfaces (arrow).

If the end play is too high, regrind face a on 1st bearing journal of camshaft.

|

|

||

|

|

|||

|

105-14778/1

|

|||

|

|

|||

|

05.8-225/2

|

|||

|

|

|||