Facing cylinder head mating surface

|

|

||||||

|

01—418 Facing cylinder head mating surface

|

||||||

|

|

||||||

|

Data

|

||||||

|

|

||||||

|

Total cylinder head height

|

93.9-94.0

|

|||||

|

|

||||||

|

Min. height after machining

|

93.1

|

|||||

|

|

||||||

|

Permissible unevenness of mating surfaces

|

in longitudinal direction

|

0.08

|

||||

|

|

||||||

|

in cross direction

|

0.0

|

|||||

|

|

||||||

|

Permissible deviation in parallel of upper mating surface to lower mating surface in longitudinal direction

|

0.1

|

|||||

|

|

||||||

|

Peak to valley height

|

0.010

|

|||||

|

|

||||||

|

Pressure test with air under water in bar gauge pressure

|

||||||

|

|

||||||

|

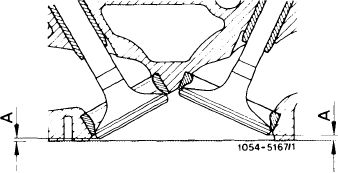

Minimum distance A with new valves and new valve seats, cylinder head parting surface not machined

|

Minimum distance A with new valves and new valve seats, cylinder head parting surface 0.4 mm milled off

|

|||||

|

|

||||||

|

Intake

|

3.3

|

2.9

|

||||

|

|

||||||

|

Valve retainer dia. 37 mm

|

0.6

|

0.2

|

||||

|

|

||||||

|

Exhaust

|

||||||

|

|

||||||

|

Valve retainer dia. 39 mm

|

0.04

|

0.36 standout

|

||||

|

|

||||||

|

Max. distance A with new valves and machined valve seats, cylinder head parting surface not machined

|

Max. distance A with new valves and machined valve seats, cylinder head parting surface 0.4 mm milled off

|

|||||

|

|

||||||

|

Intake

|

4.2

|

3.8

|

||||

|

|

||||||

|

Valve retainer dia. 37 mm 1.5

|

1.1

|

|||||

|

|

||||||

|

Exhaust

|

||||||

|

|

||||||

|

Valve retainer dia. 39 mm

|

0.94

|

0.54

|

||||

|

|

||||||

|

Max. distance A is reduced by the same dimension by which the cylinder head parting surface has been machined down.

|

||||||

|

|

||||||

|

||||||

|

|

||||||

|

01.2-418/1 F3

|

||||||

|

|

||||||

|

|

|||

|

Conventional tools

|

|||

|

|

|||

|

Surface grinding machine with milling equipment for light alloy surface

|

e.g. made by Ruaro u. Fi., Schio/ltaly Scledum, type RTY

|

||

|

|

|||

|

Knife-edged straightedge approx. 750 mm long

|

|||

|

|

|||

|

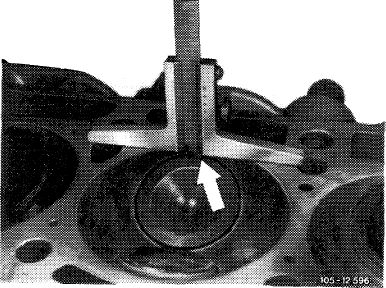

Facing

|

|

||

|

Only 0.4 mm material can be machined off of the cylinder head at the mating surfaces to the crankshaft and camshaft housing.

A distorted cylinder head must always be faced on both mating surfaces.

Machine valve seats until the permissible distance A between the valve head and cylinder head mating surface is reached.

The timing must be adjusted, if a cylinder head mating surface is faced (05—215).

|

|||

|

|

|||

|

01.2-418/2 F3

|

|||

|

|

|||

Poprzedni