Sealing coolant pump

|

|

|||

|

20—225 Sealing coolant pump

|

|||

|

|

|||

|

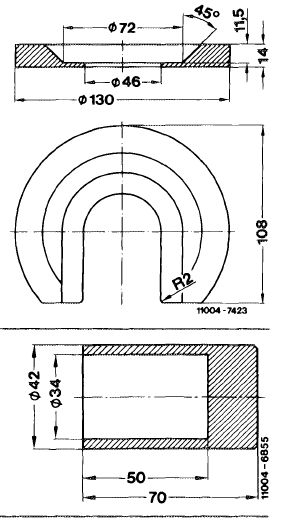

Self-made tools

|

|||

|

|

|||

|

Pressing-off disk for impeller

|

|

||

|

Pressing-in sleeve

|

|||

|

|

|||

|

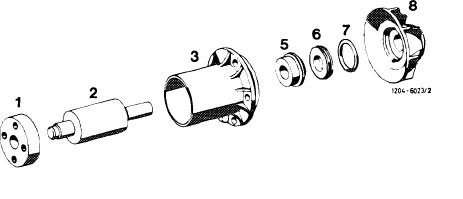

1 Fan hub 5 Slide ring seal

2 Coolant pump shaft with 6 Countering compact bearing 7 O-ring

3 Bearing housing 8 Impeller

|

|

||

|

|

|||

|

20.8-225/1 F 2

|

|||

|

|

|||

|

|

|||

|

Disassembly

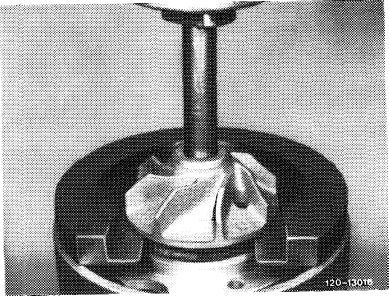

1 Press off impeller. For this purpose, place pressing-off disk between impeller and bearing housing.

|

|

||

|

|

|||

|

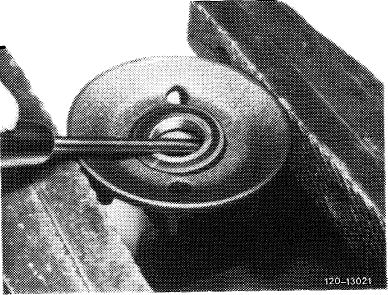

2 Apply light hammer blows at several points between bearing housing and sliding ring seal to cancel the preload and force sliding ring seal out.

|

|

||

|

|

|||

|

3 Force counterring out of impeller.

|

|

||

|

|

|||

|

Assembly

|

|

||

|

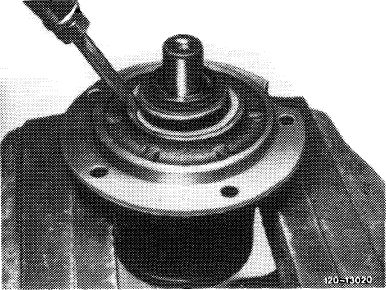

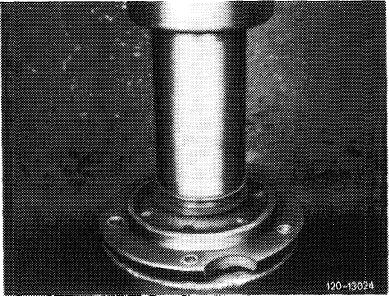

4 Slightly coat mounting bores of sliding ring seal in bearing housing with sealing compound (part No. 001 989 25 20).

Press-in or knock-in sliding ring seal by means of pressing-in sleeve.

Attention!

Support at bearing housing only and not at coolant pump shaft.

|

|||

|

|

|||

|

20.8-225/2 F 2

|

|||

|

|

|||

|

|

|||

|

5 Coat O-ring on counterring with brake cylinder paste and push with chamfered side (arrow) into thoroughly cleaned impeller.

|

|

||

|

|

|||

|

120 -10863

|

|||

|

|

|||

|

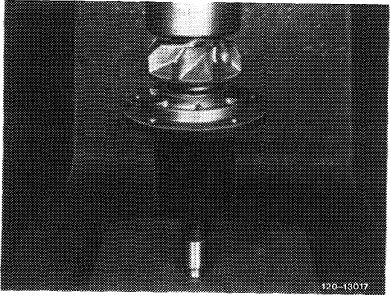

6 Clean sealing surfaces of counterring and sliding ring seal free ob dust by means of chamois cloth.

7 Degrease shaft stub of coolant pump shaft and impeller bore.

8 Press-on impeller flush with shaft while supporting coolant pump shaft.

|

|

||

|

|

|||

|

20.8-225/3 F 2

|

|||

|

|

|||