Reconditioning of coolant pump

|

|

||||

|

20—220 Reconditioning of coolant pump

|

||||

|

|

||||

|

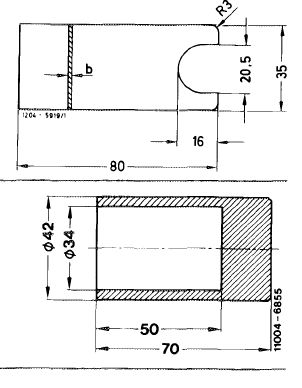

Self-made tools

|

||||

|

|

||||

|

Spacing plate b = 2 mm

|

|

|||

|

Pressing-in sleeve

|

||||

|

|

||||

|

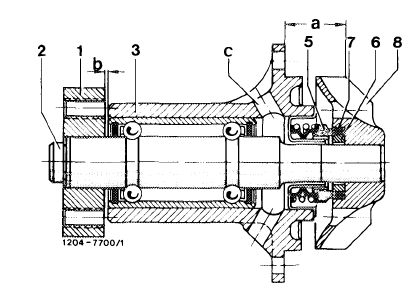

1 Fan hub

2 Coolant pump shaft with compact bearing

3 Bearing housing

5 Slide ring seal

6 Counterring

|

7 O-ring

8 Impeller

a 22.8—23.2 mm

b 2 mm

c Vent holes

|

|

||

|

|

||||

|

Disassembly

|

|

|||

|

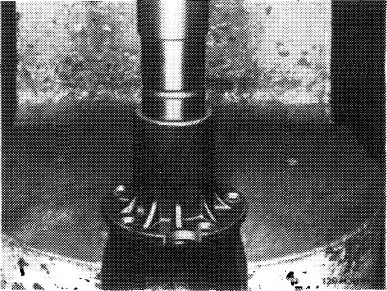

1 Support bearing housing with pertinent tubing and press out coolant pump shaft by means of a mandrel.

2 Knock sliding ring seal out of bearing housing.

|

||||

|

|

||||

|

20.8-220/1 F 2

|

||||

|

|

||||

|

|

||||

|

3 Remove counterring from impeller.

Note: Always replace compact bearing and fan hub following disassembly.

|

|

|||

|

|

||||

|

Assembly

|

|

|||

|

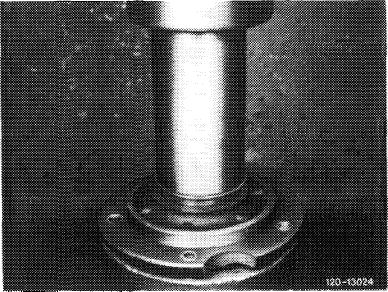

4 Press in new compact bearing flush with bearing housing by means of a tube positioned against outer race.

Do not press against coolant pump shaft.

|

||||

|

|

||||

|

5 Coat mounting bore of sliding ring seal in bearing housing slightly with sealing compound (part No. 001 989 25 20).

Press-in or knock-in sliding ring seal with pressing-in sleeve.

Attention!

Support only against bearing housing and not against coolant pump shaft.

|

|

|||

|

|

||||

|

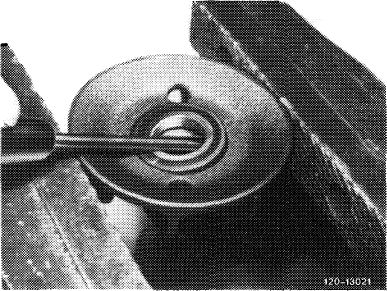

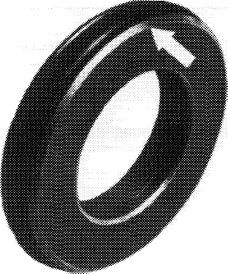

6 Coat O-ring on counterring with brake cylinder paste and push with chamfered side (arrow) into thoroughly cleaned impeller.

|

|

120 -10863

|

||

|

|

||||

|

20.8-220/2 F 2

|

||||

|

|

||||

|

|

|||

|

7 Clean sealing surfaces of counterring and sliding ring seal free of dust by means of a chamois cloth.

8 Degrease both shaft stubs and impeller in bore.

9 Press-on impeller flush with shaft while supporting coolant pump shaft.

|

|

||

|

|

|||

|

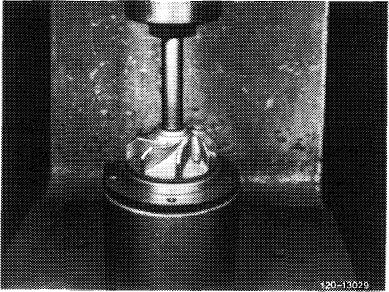

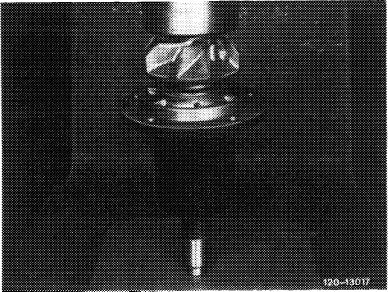

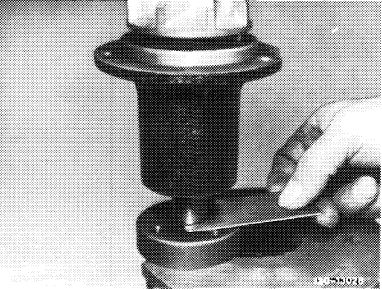

10 Heat fan hub on a hot plate to approx. 300 °C (annealing color dark — up to light blue).

Place heated fan hub on a recessed base. Hold spacing plate on coolant pump shaft, slip coolant pump shaft on fan hub and apply a blast of compressed air against hub. Wait for a few seconds until fan hub is firm and then cool immediately in water bath.

|

|

||

|

|

|||

|

20.8-220/3 F 2

|

|||

|

|

|||

Poprzedni

Removal and installation of coolant pump

Nowsze