Removal and installation of oil spray nozzles

|

|

||||

|

18—040 Removal and installation of oil spray nozzles

|

||||

|

|

||||

|

Note

|

|

|||

|

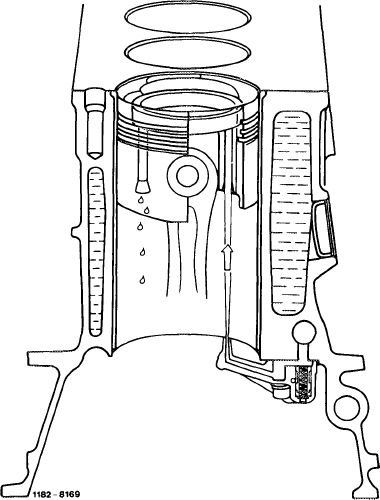

Due to the higher thermic load, the pistons are cooled via a ring duct located in piston crowns.

The required oil for the pistons is provided by oil spray nozzles located underneath cylinder bores at the left (driving direction).

The oil spray nozzles in turn are connected to engine oil circuit via the main oil duct in cylinder crankcase.

|

||||

|

|

||||

|

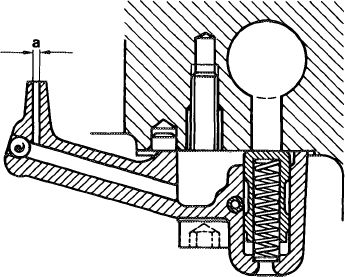

Starting at an engine oil pressure of 1.0—1.5 bar gage pressure, the valve located in oil spray nozzle opens.

An oil jet will come out of nozzle bore (a), aimed accurately into feed bore in piston.

|

|

1034 – 8067

|

||

|

a = 1.5 mm dia.

|

||||

|

|

||||

|

The ring duct (7 mm dia.) distributes the oil in piston crown, absorbs heat and flows back to oil pan through return flow bore.

Valve in oil spray nozzle closes at 1 bar gage pressure at the latest.

|

||||

|

|

||||

|

18.8-040/1 F 2

|

||||

|

|

||||

|

|

|||

|

Since piston cooling is of considerable importance for life of engine, proper functioning of oil spray nozzles is extremely important.

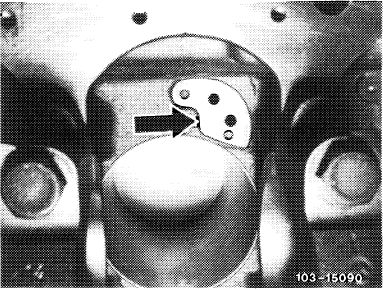

It is also very important that in each piston position the oil jet sprays accurately into feed bore on piston.

|

|||

|

|

|||

|

To prevent plugging of nozzle bore (a) by particles of dirt, make sure that during assembly jobs no dirt will settle at clean oil end of oil circuit.

Remove oil spray nozzles for cleaning cylinder crank-case. Do not mix up oil spray nozzles.

|

|||

|

|

|||

|

Removal

|

|||

|

|

|||

|

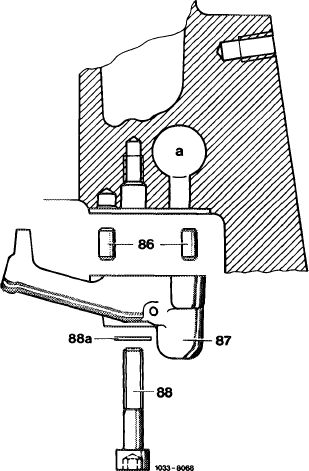

1 Completely remove oil pan (01—310).

2 Position crankshaft in such a manner that the respective oil spray nozzle is accessible.

3 Unscrew screw (88).

4 Pull out oil spray nozzle.

When pulling out oil spray nozzle, do not cant nozzle and do not hold nozzle at nozzle neck.

|

|

||

|

86 Cylindrical pin

87 Oil spray nozzle

88 Hex. socket screw 88a Washer

a Main oil duct

|

|||

|

|

|||

|

18.8-040/2 F2

|

|||

|

|

|||

|

|

|||

|

5 Cover or close oil feed bores in cylinder crankcase.

|

|

||

|

|

|||

|

Installation

|

|||

|

|

|||

|

Attention!

The installation of oil spray nozzles with heavily out-of-round nozzle bore or with burr at nozzle outlet is no longer permitted.

|

|||

|

|

|||

|

6 Blow out oil spray nozzle with compressed air, with direction of air flow corresponding to direction of oil flow.

Do not position compressed air hose at nozzle bore. Also do not use hard objects for cleaning nozzle bore.

|

|||

|

|

|||

|

7 Remove covers on oil feed bores in cylinder crank-case.

8 Position oil spray nozzle vertically to parting surface on cylinder crankcase and press on.

9 Screw-in screw (88) and tighten to 10 Nm.

10 Install oil pan (01-310).

|

|||

|

|

|||

|

18.8-040/3 F 2

|

|||

|

|

|||