Removal and installation of exhaust gas turbocharger

|

|

||||

|

09—430 Removal and installation of exhaust gas turbocharger

|

||||

|

|

||||

|

Turbocharger designation

|

||||

|

|

||||

|

Garret

|

TA 0301

|

|||

|

|

||||

|

Kiihnle Kopp and Kausch KKK 532 679 60 31;

|

||||

|

|

||||

|

x) Start of production

World-wide except<@): January 1983 (us£): February 1983

|

|

|||

|

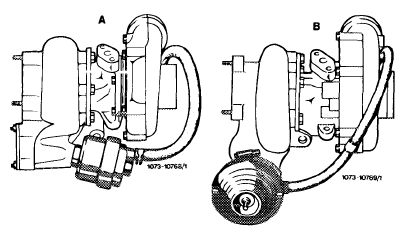

A Garret turbocharger B KKK turbocharger

|

||||

|

|

||||

|

Removal

|

|

|||

|

1 Remove air filter, detaching air filter cover and unscrewing 3 fastening nuts.

|

||||

|

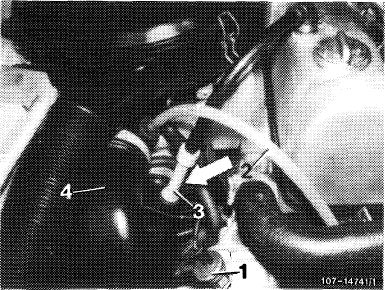

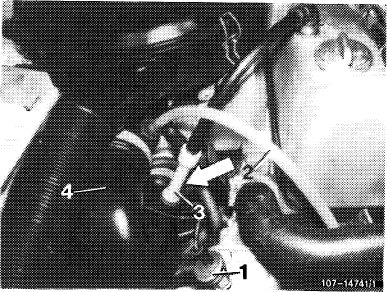

2 On vehicles with automatic climate control or air-conditioning remove electric line for

100° C temperature switch (1).

3 Release lower hose clip (arrow) on intake line (4) from air filter to compressor housing. On vehicles up to model 1979 only.

4 Remove vacuum line (2) and crankcase ventilation pipe (3).

5 Remove air filter with intake line (4).

|

||||

|

||||

|

1 Temperature switch 100 C

2 Vacuum line

3 Crankcase ventilation pipe

4 Intake line

|

||||

|

|

||||

|

09.8-430/1 F 3

|

||||

|

|

||||

|

|

|||

|

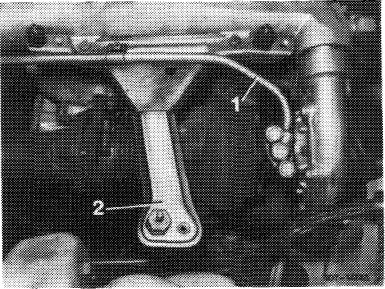

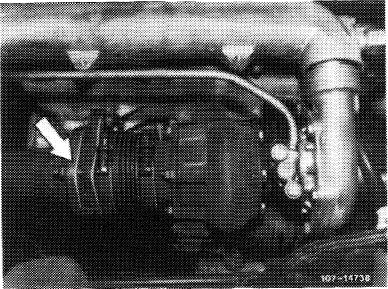

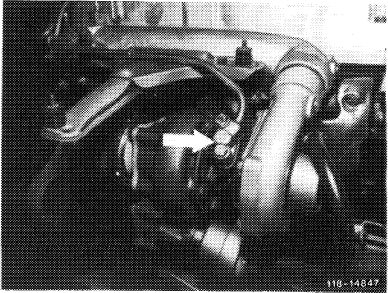

6 Unscrew engine oil supply line (1).

7 Unscrew air filter holder (2). To do so, release 3 hex-head bolts (2 from above, 1 from below) and remove holder.

|

|

||

|

1 Engine oil supply line

2 Air filter holder

|

|||

|

|

|||

|

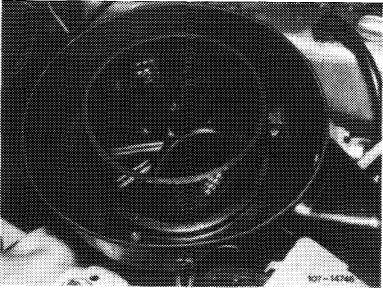

8 Unscrew exhaust flange (arrow).

9 Release and remove exhaust holder on automatic transmission.

10 Force exhaust pipe toward rear.

|

|

||

|

|

|||

|

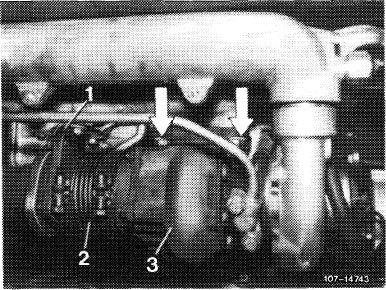

11 Unscrew holder (1) for adapter fitting (2).

12 Unscrew 4 fastening nuts (arrows) at exhaust-driven turbocharger and remove turbocharger.

13 Unscrew adapter fitting (2) at exhaust-driven turbocharger (3).

|

|

||

|

1 Holder

2 Adapter fitting

3 Turbocharger

|

|||

|

|

|||

|

09.8-430/2 F 3

|

|||

|

|

|||

|

|

|||

|

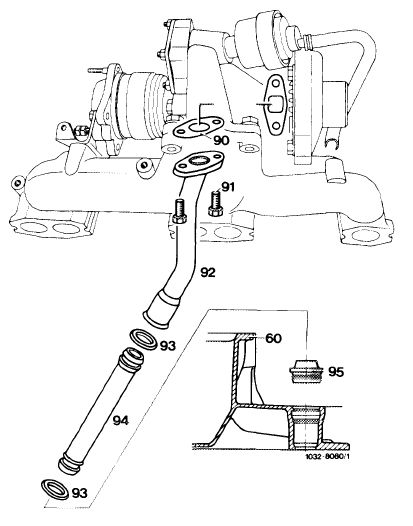

14 Unscrew oil return pipe (92) at turbocharger.

|

|

||

|

60 Oil pan, upper part

90 Gasket

91 2 bolts M 8 x 20

92 Oil return pipe (upper part)

93 O-ring

94 Oil return pipe (lower part)

95 Sectional seal

|

|||

|

|

|||

|

Installation

|

|||

|

|

|||

|

Install in reverse order, using new gaskets (repair set). Please note the following points:

15 Prior to installing turbocharger, attach adapter fitting and oil return pipe. Correct positioning is absolutely essential.

|

|||

|

|

|||

|

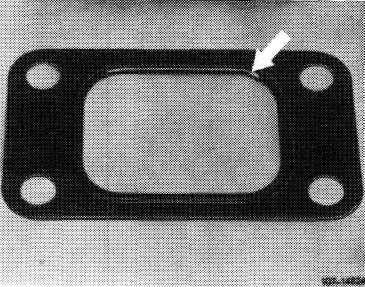

16 Insert flange gasket between turbocharger and exhaust manifold so that bead (arrow) is at exhaust manifold side.

17 Always use heat-resistant nuts and bolts to

attach the turbocharger.

|

|

||

|

|

|||

|

09.8-430/3 F 3

|

|||

|

|

|||

|

|

|||

|

18 Prior to using a replacement turbocharger, fill with approx. 1/8 I engine oil through engine oil supply hole (arrow).

|

|

||

|

|

|||

|

19 Make sure that intake line (4) is fitted in such a way that rubber sealing rings are correctly positioned.

|

|

||

|

1 Temperature switch

2 Vacuum line

3 Ventilation pipe

4 Intake line

|

|||

|

|

|||

|

09.8-430/4 F 3

|

|||

|

|

|||

|

|

||||

|

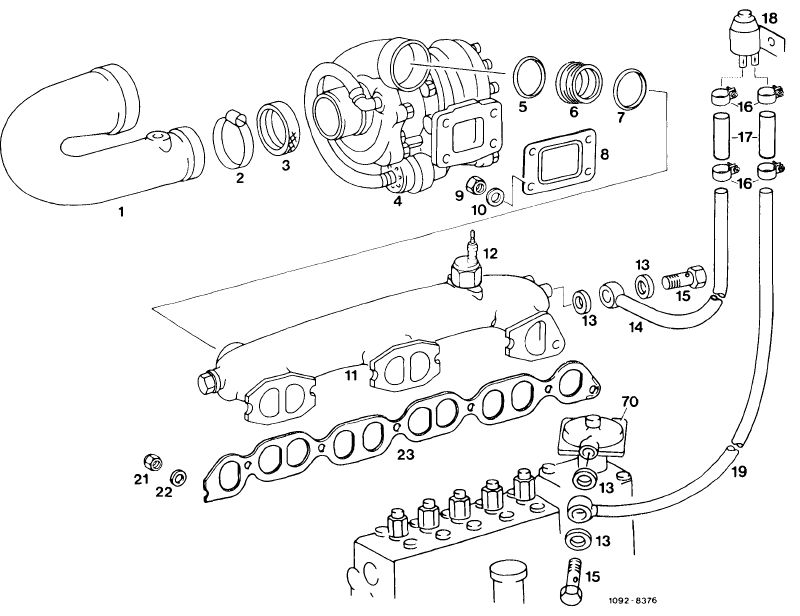

A. Exhaust Gas Turbocharger

|

||||

|

|

||||

|

||||

|

|

||||

|

1 Intake line

2 Hose clip

3 Rubber sealing ring

4 Turbocharger

5 Rubber sealing ring

6 Adapter fitting

7 Rubber sealing ring

8 Flange gasket

|

9 Heat-resistant nut 1 7

10 Washer 18

11 Intake manifold 19

12 Pressure switch 21

13 Sealing ring 22

14 Delivery line from intake manifold 23

15 Union screw 70

16 Hose clip

|

Connecting hose

Switchover valve

Delivery line to aneroid compensator

Nut

Washer

Gasket

Aneroid compensator

|

||

|

|

||||

|

09.8-430/5 F 3

|

||||

|

|

||||