Renewal of rocker arms and rocker arm bearing brackets

|

|

|||||||||||||||||||||||||||||||||||||||||||||||

|

05—240 Renewal of rocker arms and rocker arm bearing brackets

|

|||||||||||||||||||||||||||||||||||||||||||||||

|

|

|||||||||||||||||||||||||||||||||||||||||||||||

|

Valve clearance

|

with engine cold (approx. 20 °C) with engine warm (60 °C ± 15 °C)

|

||||||||||||||||||||||||||||||||||||||||||||||

|

|

|||||||||||||||||||||||||||||||||||||||||||||||

|

Intake

|

0.101)

|

0.151)

|

|||||||||||||||||||||||||||||||||||||||||||||

|

|

|||||||||||||||||||||||||||||||||||||||||||||||

|

Exhaust

|

0.35

|

0.40

|

|||||||||||||||||||||||||||||||||||||||||||||

|

|

|||||||||||||||||||||||||||||||||||||||||||||||

|

M 0.05 mm higher during lasting outside temperatures below —20 °C.

|

|||||||||||||||||||||||||||||||||||||||||||||||

|

|

|||||||||||||||||||||||||||||||||||||||||||||||

|

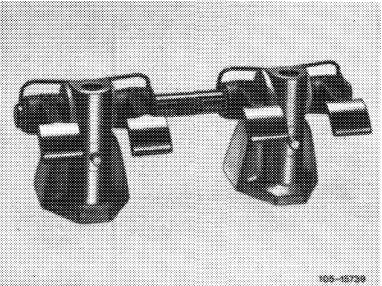

Rocker arms, rocker arm brackets and shaft

|

|||||||||||||||||||||||||||||||||||||||||||||||

|

|

|||||||||||||||||||||||||||||||||||||||||||||||

|

|||||||||||||||||||||||||||||||||||||||||||||||

|

|

|||||||||||||||||||||||||||||||||||||||||||||||

|

(open bushing)

|

|||||||||||||||||||||||||||||||||||||||||||||||

|

|

|||||||||||||||||||||||||||||||||||||||||||||||

|

ID of bushing

|

final dimension

|

12.00 12.02

|

|||||||||||||||||||||||||||||||||||||||||||||

|

|

|||||||||||||||||||||||||||||||||||||||||||||||

|

|||||||||||||||||||||||||||||||||||||||||||||||

|

|

|||||||||||||||||||||||||||||||||||||||||||||||

|

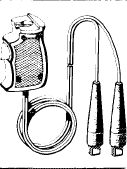

Valve adjusting wrench 14 mm (2 each)

|

|

615 589 00 01 00

|

|||||||||||||||||||||||||||||||||||||||||||||

|

Holding wrench for valve spring retainer

|

11004-7118 ‘

|

615 589 00 03 00

|

|||||||||||||||||||||||||||||||||||||||||||||

|

Socket 27 mm, 1/2″ square, for rotating engine

|

001 589 65 09 00

|

||||||||||||||||||||||||||||||||||||||||||||||

|

|

|||||||||||||||||||||||||||||||||||||||||||||||

|

05.8-240/1 F 2

|

|||||||||||||||||||||||||||||||||||||||||||||||

|

|

|||||||||||||||||||||||||||||||||||||||||||||||

|

|

||||

|

Contact handle for rotating engine (component of compression pressure recorder 001 589 46 21 00)

|

|

001 589 46 21 08

|

||

|

11004-6487

|

||||

|

|

||||

|

Note

|

|

|||

|

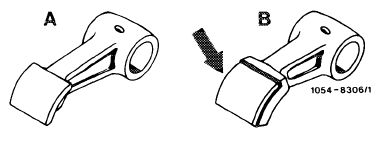

There are two rocker arm versions:

|

||||

|

1st version

|

||||

|

|

||||

|

Rocker arm with inductance-hardened and hard-chromed running surface (A) for camshaft made of malleable cast iron (code number 00).

|

||||

|

|

||||

|

2nd version

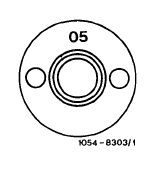

Rocker arm with brazed-on carbide facing as running surface (B, arrow), for camshafts made of chilled cast iron (code number 05 and 08).

Code number is punched into rear end of camshaft.

|

|

|||

|

|

||||

|

Attention!

Do not mix up rocker arms, since this will lead to destruction of cam and of rocker arm running surface.

During renewal, make sure whether rocker arm has a bushing or not.

Rocker arms without bushing should be scrapped.

On rocker arms with bushings, bushing can be renewed.

|

||||

|

|

||||

|

05.8-240/2 F 2

|

||||

|

|

||||

|

|

|||

|

Removal

|

|

||

|

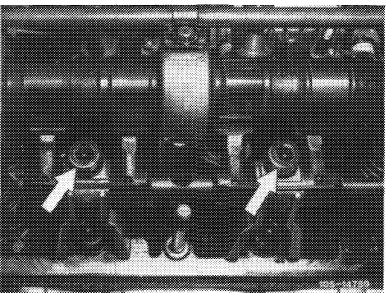

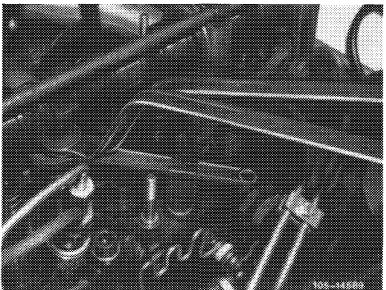

1 Completely remove rocker arm groups (05—235).

|

|||

|

|

|||

|

2 Push down tensioning springs of rocker arm brackets.

|

|

||

|

|

|||

|

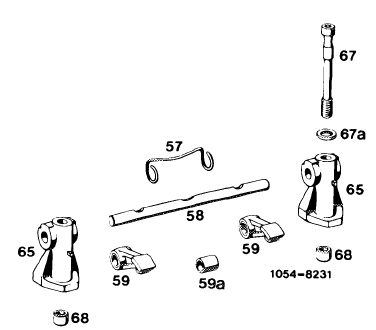

3 Pull tensioning spring (57), bearing brackets (65) and rocker arm (59) from rocker arm shaft (58).

|

|

||

|

57 Tensioning spring

58 Rocker arm shaft

59 Rocker arm

59a Rocker arm bearing bushing 65 Bearing bracket

67 Screw 67a Washer

68 Fitted sleeve

|

|||

|

|

|||

|

Installation

|

|

||

|

4 Slip tensioning spring (57), rocker arm (59) and bearing brackets (65) on rocker arm shaft (58).

5 Slip tensioning spring with second eye on rocker arm shaft and push into groove of bearing brackets.

6 Completely install rocker arm groups (05—235).

7 Adjust valve clearance (05—210).

|

|||

|

|

|||

|

05.8-240/3 F 2

|

|||

|

|

|||