Knocking-out and inserting steel balls for main oil ducts

|

|

|||

|

01—130 Knocking-out and inserting steel balls for main oil ducts

|

|||

|

|

|||

|

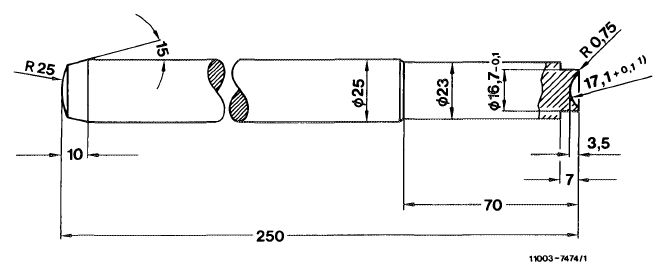

Self-made tool

|

|||

|

|

|||

|

Mandrel for knocking-in steel ball

|

refer to Fig. item 9

|

||

|

|

|||

|

Note

|

|

||

|

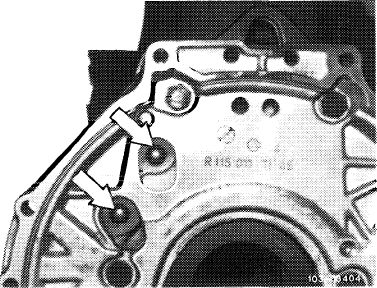

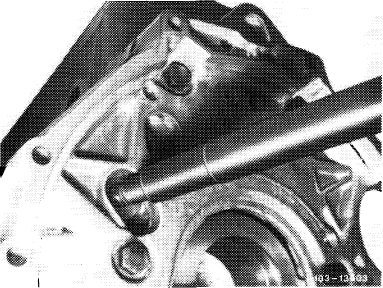

The main oil ducts in cylinder crankcase are closed at transmission end by means of a steel ball (17 mm dia.) (arrows).

|

|||

|

|

|||

|

During engine repairs, the steel balls must be knocked out to clean main oil ducts.

Undamaged steel balls can be used several times without refinishing ball seat.

Replace damaged steel balls.

|

|

||

|

|

|||

|

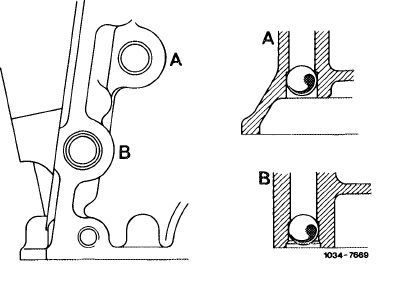

In the event of leaks, reset steel balls with knocking-in mandrel approx. 1 mm (dimension is indicated on knocking-in mandrel).

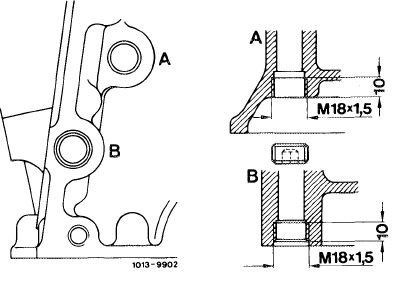

If the leaks are then not yet eliminated, knock-out the respective steel ball and replace by closing plug M 18 x 1.5, part no. 000 906 018 000.

For this purpose, cut thread M 18 x 1.5 to a depth of 10 mm as shown on drawing.

|

|

||

|

01.8-130/1 F2

|

|||

|

|

|||

|

|

|||

|

Thoroughly remove chips from oil duct.

Cpat closing plug M 18 x 1.5 with sealing glue, part no. 002 989 94 71 and screw in.

|

|||

|

|

|||

|

Upper main oil duct Knocking-out

|

|

||

|

1 Remove transmission and flywheel (03—410).

2 Remove radiator (20-420).

3 Unscrew closing plug (1) and adjacent hex. nut.

4 Knock out steel ball from the front by means of a round steel bolt (13 mm dia.) approx. 850 mm long.

|

|||

|

|

|||

|

Lower main oil duct Knocking-out

|

|||

|

|

|||

|

1 Remove transmission and flywheel (03—410).

2 Remove radiator (20-420).

3 Remove pulley, vibration damper and balancing disc (03-340).

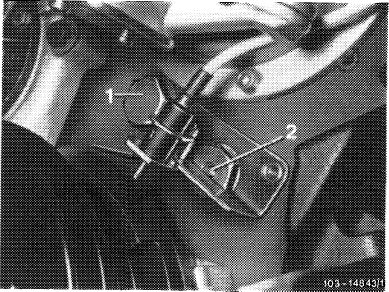

4 Unscrew closing plugs (1 and 2).

5 Remove inner slide rail in cylinder crankcase (05-340).

6 Tilt engine slightly toward the rear.

7 Knock out steel ball from the front by means of a round steel bolt (13 mm dia.) approx. 850 mm long.

|

|||

|

|

|||

|

01.8-130/2 F2

|

|||

|

|

|||

|

|

||||

|

Upper and lower main oil duct

|

||||

|

|

||||

|

Knocking-in

|

||||

|

|

||||

|

8 Thoroughly clean bore in pressing-in range of steel ball.

9 Coat spherical cup on self-made knocking-in mandrel with grease and place steel ball into cup.

|

|

|||

|

|

||||

|

3-13405

|

||||

|

|

||||

|

Knocking-in mandrel

Material: C 45

M 17.1 +0.1 = ball dia.

|

|

|||

|

|

||||

|

10 Position steel ball by means of knocking-in mandrel and knock in up to stop on mandrel.

11 Mount all removed parts.

12 Run engine warm and check for leaks.

|

|

|||

|

|

||||

|

01.8-130/3 F2

|

||||

|

|

||||