Checking and machining valves

|

|

|||||||||||||||||||||||||||||||||||||||||||||||||

|

05—280 Checking and machining valves

|

|||||||||||||||||||||||||||||||||||||||||||||||||

|

|

|||||||||||||||||||||||||||||||||||||||||||||||||

|

|||||||||||||||||||||||||||||||||||||||||||||||||

|

|

|||||||||||||||||||||||||||||||||||||||||||||||||

|

when new

|

2.54

|

2.49

|

|||||||||||||||||||||||||||||||||||||||||||||||

|

|

|||||||||||||||||||||||||||||||||||||||||||||||||

|

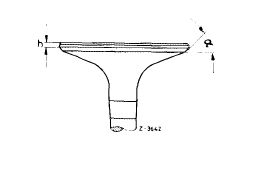

Height “h” of valve retainer

|

|||||||||||||||||||||||||||||||||||||||||||||||||

|

|

|||||||||||||||||||||||||||||||||||||||||||||||||

|

limit value

|

2.0

|

2.0

|

|||||||||||||||||||||||||||||||||||||||||||||||

|

|

|||||||||||||||||||||||||||||||||||||||||||||||||

|

Adjusting angle for machining valves

|

30 + 15′

|

||||||||||||||||||||||||||||||||||||||||||||||||

|

|

|||||||||||||||||||||||||||||||||||||||||||||||||

|

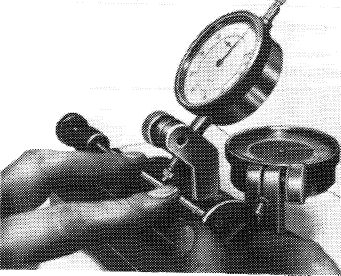

Permissible runout at valve stem and valve seat max.

|

0.03

|

||||||||||||||||||||||||||||||||||||||||||||||||

|

|

|||||||||||||||||||||||||||||||||||||||||||||||||

|

Valve shaft wear (wear limit)

|

0.05

|

||||||||||||||||||||||||||||||||||||||||||||||||

|

|

|||||||||||||||||||||||||||||||||||||||||||||||||

|

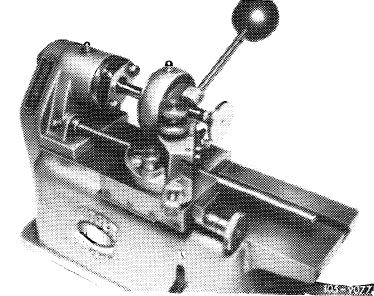

Conventional tools

|

|||||||||||||||||||||||||||||||||||||||||||||||||

|

|

|||||||||||||||||||||||||||||||||||||||||||||||||

|

Valve cone grinder

or

valve cone machining tool

|

e.g. made by Matra-Werke GmbH

D-6000 Frankfurt/Main 8

e.g. made by Hunger, D-8000 Miinchen

|

||||||||||||||||||||||||||||||||||||||||||||||||

|

|

|||||||||||||||||||||||||||||||||||||||||||||||||

|

Note

|

|||||||||||||||||||||||||||||||||||||||||||||||||

|

|

|||||||||||||||||||||||||||||||||||||||||||||||||

|

Exhaust valves are filled with sodium.

When scrapping valves, pay attention to safety rules. Do not melt valves filled with sodium, since there is a risk of explosion, and do not use such valves for making tools (punch, etc.), without first removing filled-in sodium.

|

|||||||||||||||||||||||||||||||||||||||||||||||||

|

|

|||||||||||||||||||||||||||||||||||||||||||||||||

|

05.8-280/1 F 2

|

|||||||||||||||||||||||||||||||||||||||||||||||||

|

|

|||||||||||||||||||||||||||||||||||||||||||||||||

|

|

|||

|

Be careful when removing sodium from valve, since sodium mixed with water and watery solutions reacts heavily explosive, while the resulting hydrogen gas may cause fires.

Sodium from cut-up or broken-up valves can be neutralized in a mixture comprising 2 liters of spirit of alcohol and 1 liter of water put into a vessel and placed in the open air.

Valves filled with sodium can be collected and shipped for neutralizing to: Garantieprtifstelle Werk Stuttgart-Unterturkheim.

|

|||

|

|

|||

|

Checking and machining

|

|

||

|

1 Clean valves and check visually.

Valves with a burnt valve retainer, with insufficient height “h” of valve retainer and valves with worn out or scored valve stem should be replaced.

|

|||

|

|

|||

|

2 Measure runout on valve stem. If runout exceeds 0.03 mm, replace valve.

|

|

||

|

|

|||

|

3 Machine valve seat.

Refer to operating instructions of machining tool and make sure of a 30° adjusting angle.

4 Measure runout on valve seat and height “h” of valve retainer.

As soon as the limit values are attained, replace valve.

|

|

||

|

|

|||

|

05.8-280/2

|

|||

|

|

|||

Poprzedni