Renewing contact breakers (breaker points)

|

|

||||

|

07.5—505 Renewing contact breakers (breaker points)

|

||||

|

|

||||

|

Closing angle (dwell angle)

|

||||

|

|

||||

|

Normal coil ignition

|

||||

|

|

||||

|

Closing angle (dwell angle) Testing and adjusting value at idle1)

|

Change between idle and 3000/min

|

|||

|

|

||||

|

39-42

|

max. ± 3

|

|||

|

|

||||

|

*)When installing new breaker points, adjust closing angle (dwell angle) to 42 ± 1°.

|

||||

|

|

||||

|

Transistorized ignition system (T) (us

|

||||

|

|

||||

|

Identification: blue ignition coil, two pre-resistors and transistorized switchgear.

|

||||

|

|

||||

|

Closing angle (dwell angle) Testing and adjusting value at idle2)

|

Change between idle and 3000/min

|

|||

|

|

||||

|

34-40

|

max. ± 3

|

|||

|

|

||||

|

2) When installing new and when adjusting used breaker points, adjust dwell angle to 34 ± 1(

|

||||

|

|

||||

|

Special tools

|

||||

|

|

||||

|

Digital tester

|

|

001 589 54 21 00

|

||

|

|

||||

|

Connecting cable

|

|

000 589 04 90 00

|

||

|

|

||||

|

’:’ fi

|

||||

|

|

||||

|

Intermediate plug (adaptor)

|

000 589 72 63 00

|

|||

|

|

||||

|

Trigger

|

|

000 589 71 63 00

|

||

|

|

||||

|

Conventional tools

|

||||

|

|

||||

|

Closing angle (dwell angle) measuring instrument

|

||||

|

|

||||

|

07.5.2 lb-505/1

|

||||

|

|

||||

|

|

|||

|

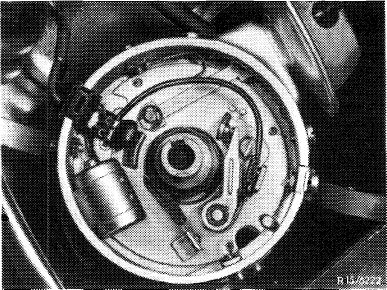

Installation

|

|

||

|

When renewing contacts, proceed as follows:

1 Wipe contacts prior to installation with a lintfree cloth to remove moisture or grease.

|

|||

|

|

|||

|

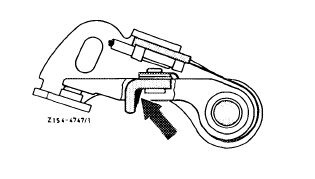

2 Coat slide piece of contact breaker, its bearing point and the cams of the distributor shaft with some Bosch special grease Ft 1 v 4.

3 When closed, contact breakers must be in parallel and at similar level in relation to each other.

|

|||

|

|

|||

|

Arrow: spot to be greased

|

|

||

|

|

|||

|

4 Set closing angle (dwell angle) to specified value.

Mount protective breaker cap. Cap protects contact against grease, oil or dirt particles.

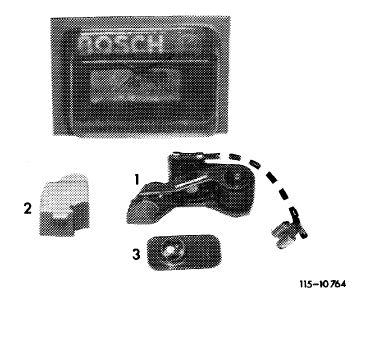

To make sure that during installation of breaker points the slide piece is greased and the protective cap is mounted, the breaker points are supplied with grease capsule and protective cap from now on.

|

|

||

|

1 Breaker point

2 Protective cap

3 Grease capsule

|

|||

|

5 Check firing point and adjust (07.5—500).

|

|||

|

|

|||

|

07.5.2 lb-505/2

|

|||

|

|

|||