Subsequent installation of modified adjusting pin for air valve preload of stage II

|

|

||||

|

07.2-175 Subsequent installation of modified adjusting pin for air valve preload of stage II

|

||||

|

|

||||

|

Testing and adjusting values

|

||||

|

|

||||

|

National version

|

Adjusting weight

|

Length1)

|

||

|

|

||||

|

1976

|

170 + 2

|

190

|

||

|

|

||||

|

1976

|

160 ±2

|

180

|

||

|

|

||||

|

Federal 1973/74

|

112 ± 2

|

125

|

||

|

|

||||

|

California 1974

|

143 + 2

|

160

|

||

|

|

||||

|

Federal and California 1975/76

|

170 ±2

|

190

|

||

|

|

||||

|

M These dimensions apply to St 37. When using other materials, the specified testing weight must be maintained. The respective length results from this weight.

|

||||

|

|

||||

|

Air valve gap

|

||||

|

|

||||

|

When loaded with adjusting weight

|

1.5 mm

|

|||

|

|

||||

|

Conventional tools

|

||||

|

|

||||

|

Hex. socket wrench 2.5 mm

|

||||

|

|

||||

|

Drill 4.6 mm dia.

|

||||

|

|

||||

|

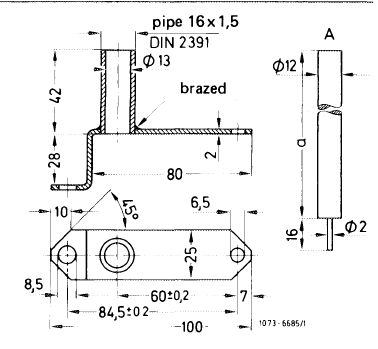

Self-made tool

|

||||

|

|

||||

|

Adjusting device for air valve of stage II

|

|

|||

|

|

||||

|

07.2.2 la—175/1

|

||||

|

|

||||

|

|

|||

|

Subsequent installation

|

|||

|

|

|||

|

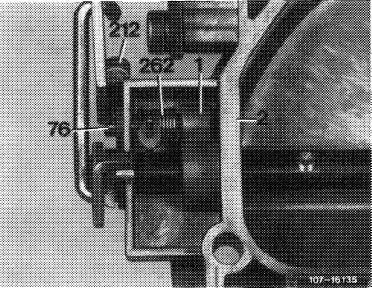

1 Remove carburetor cover (07.2—192).

2 Unscrew locking screw (212), remove adjusting pin (76) and restoring spring of adjusting pin.

|

|||

|

|

|||

|

3 Clamp carburetor cover into vise, using projective jaws.

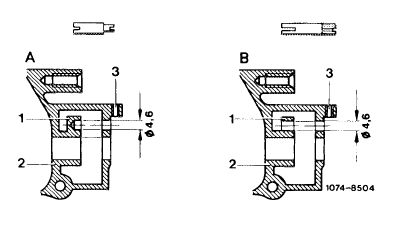

4 Extend rear mounting bore of adjusting pin. For this purpose, drill completely through housing eye (1) with a drill of 4.6 mm dia.

|

|

||

|

A Before B New

|

|||

|

|

|||

|

Attention!

Do not damage carburetor housing wall (2) toward mixing chamber while drilling.

|

|||

|

|

|||

|

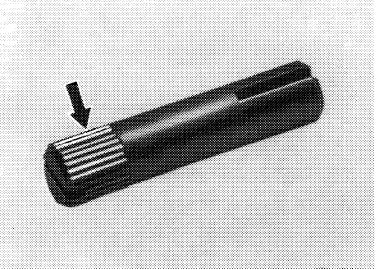

5 Install new adjusting pin with knurls and restoring spring with slide block. For this purpose, move restoring spring into installation position. Slip-in adjusting pin up to stop while turning adjusting pin.so that the restoring spring can engage in slot of driver. Install carburetor cover.

6 Complete air valve adjustment of stage II (07.2-170).

|

|

||

|

1 Housing eye

2 Carburetor housing wall 76 Adjusting pin

212 Locking screw

262 Restoring spring

|

|||

|

|

|||

|

New adjusting pin with knurls (arrow)

|

|

||

|

|

|||

|

07.2.2 la-175/2

|

|||

|

|

|||