Removal and installation of carburetor

|

|

|||||

|

07.2—194 Removal and installation of carburetor

|

|||||

|

|

|||||

|

Identification: Information plate in national language on cross member in front of radiator or on cylinder head cover. Adjust engines according to data of respective exhaust gas information plate.

|

|||||

|

|

|||||

|

Testing and adjusting values

|

|||||

|

|

|||||

|

Idle speed adjustment

|

|||||

|

|

|||||

|

National version

|

Idle speed 1/min

|

Idle speed emission value % CO

|

|||

|

|

|||||

|

up to 1976

|

max. 1.5

|

||||

|

|

|||||

|

1976

|

800-900

|

||||

|

|

|||||

|

max. 1.0 without air injection

|

|||||

|

|

|||||

|

T) 1976

|

|||||

|

|

|||||

|

<psi> 1973

|

|||||

|

|

|||||

|

750-900

|

up to 1.5

|

||||

|

|

|||||

|

1974 Federal

|

|||||

|

|

|||||

|

1974 California

|

700-900

|

6—8 without air injection

|

|||

|

|

|||||

|

1975/76

|

800-900

|

max. 1.0 without air injection

|

|||

|

|

|||||

|

Vacuum governor1)

|

|||||

|

|

|||||

|

National version

|

Engine speed

Vacuum hose pulled off

1/min

|

Engine speed

Driving position engaged

1/min

|

|||

|

|

|||||

|

without

TN choke

|

with

TN choke

|

||||

|

|

|||||

|

1976

|

|||||

|

|

|||||

|

1976

|

|||||

|

|

|||||

|

1700-1900

|

600-700

|

||||

|

|

|||||

|

1973/74

|

1200-1400

|

||||

|

|

|||||

|

1975/76

|

|||||

|

|

|||||

|

l) When engaging all auxiliary units, the engine should still run smoothly.

|

|||||

|

|

|||||

|

07.2.2 la—194/1

|

|||||

|

|

|||||

|

|

|||||||

|

Tightening torques

|

Nm

|

(kpm)

|

|||||

|

|

|||||||

|

with new insulating flange

|

10

|

(1.0)

|

|||||

|

|

|||||||

|

Carburetor fastening nuts

|

|||||||

|

|

|||||||

|

with insulating flange used up to now

|

8

|

(0.8)

|

|||||

|

|

|||||||

|

Special tools

|

|||||||

|

|

|||||||

|

f ■

|

|

||||||

|

|

|||||||

|

Oil telethermometer

|

I

|

116 589 27 21 00

|

|||||

|

|

|||||||

|

Digital tester

|

|

001 589 54 21 00

|

|||||

|

|

|||||||

|

Connecting cable 6 m long

|

000 589 04 90 00

|

||||||

|

|

|||||||

|

I1OO4-T112 \

|

|||||||

|

|

|||||||

|

Intermediate plug (adaptor)

|

000 589 72 63 00

|

||||||

|

|

|||||||

|

Trigger

|

|

000 589 71 63 00

|

|||||

|

|

|||||||

|

Torque wrench 4—16 Nm (40—160 kpcm)

|

|

000 589 67 21 00

|

|||||

|

|

|||||||

|

Conventional tools

|

|||||||

|

|

|||||||

|

Revolution counter, CO measuring instrument

|

|||||||

|

|

|||||||

|

07.2.2 la-194/2

|

|||||||

|

|

|||||||

|

|

|||

|

Removal

|

|

||

|

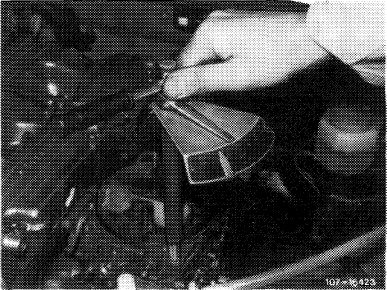

1 Remove air filter.

2 Evacuate excess pressure in cooling system by loosening radiator cap for a short moment, then tighten cap again.

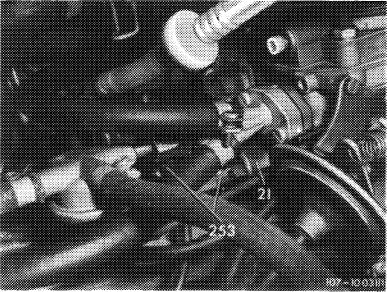

3 Unscrew fuel return valve. Pull off electric cable on choke cover, plug on idle speed shutoff valves, vacuum lines and coolant hoses. Disconnect regulating rod on carburetor.

|

|||

|

|

|||

|

4 Unscrew carburetor fastening nuts and remove carburetor.

|

|||

|

|

|||

|

Installation

|

|||

|

|

|||

|

5 Install carburetor in vice versa sequence. Proceed as follows:

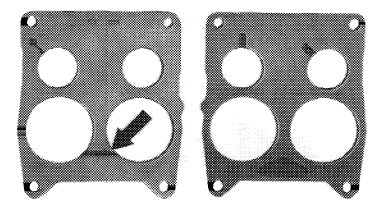

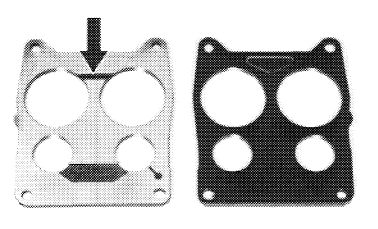

• Check insulating flange for damage and replace, if required.

• Pay attention to installation position and various insulating flange versions.

|

|||

|

|

|||

|

(@) 1973/74

(@) California 1974

Arrow = groove for drawing off fuel evaporation vapors, should point toward carburetor.

|

|

||

|

|

|||

|

CD 1976 (D 1976 (usa) 1975/76

Arrow = groove for drawing off fuel and crankcase evaporation vapors, should point toward carburetor.

Attention!

This insulating flange should no longer be installed for model years 1973/74.

|

|

||

|

|

|||

|

107-9854/1

|

|||

|

|

|||

|

07.2.2 la-194/3

|

|||

|

|

|||

|

|

|||||

|

• Tighten carburetor fastening nuts uniformly and crosswise to specified torque.

Attention!

To prevent distortion of carburetor, tighten with a torque wrench only and up to specified torque.

|

|

||||

|

|

|||||

|

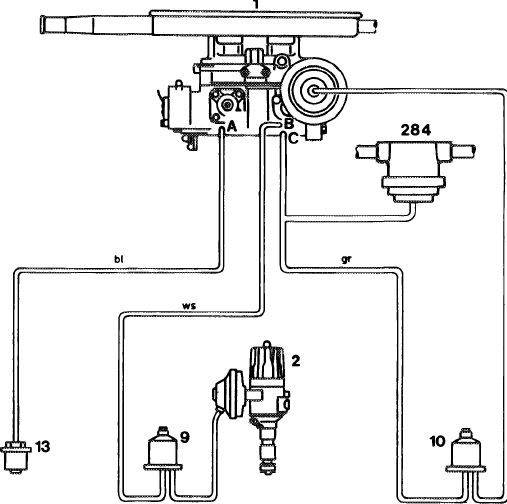

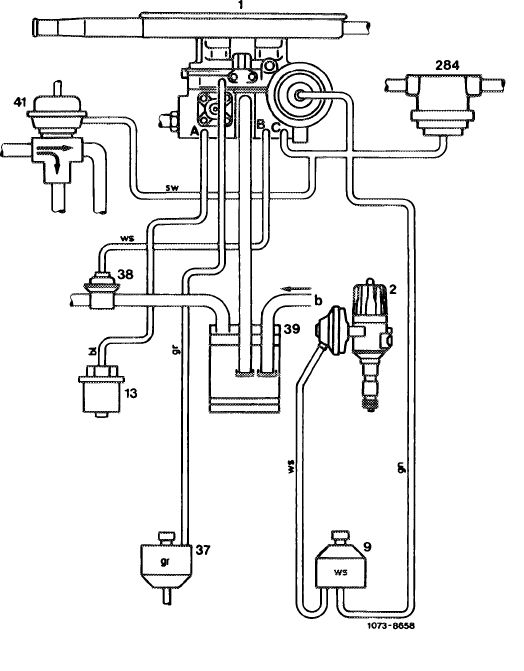

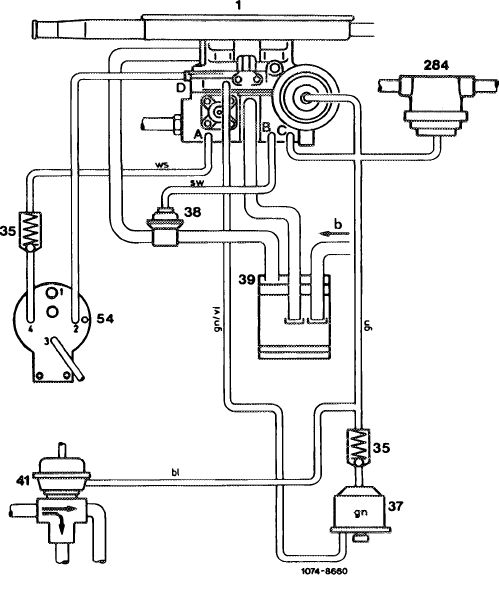

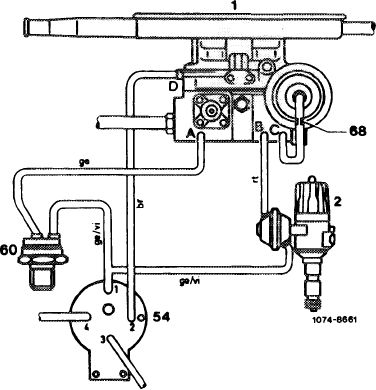

Attach vacuum lines on carburetor according to diagram.

|

|||||

|

|

|||||

|

1973/74 Federal

|

|

||||

|

A Vacuum connection for vacuum switch

(13) of ignition retard B Vacuum connection for switchover valve

(9) of ignition retard

C Vacuum connection for switchover valve

(10) of throttle valve lift by vacuum governor, as well as for fuel return valve (284)

Line colors

gr = grey bl = blue ws = white

|

|||||

|

ws

|

1073-8659

|

||||

|

|

|||||

|

07.2.2 la-194/4

|

|||||

|

|

|||||

|

|

||||

|

1974 California

|

|

|||

|

A Vacuum connection for vacuum switch (13)

of ignition adjustment B Vacuum connection for draw-off valve (38)

of fuel evaporation control system C Vacuum connection for switchover valve (9)

of ignition adjustment, decel diverter valve

of air injection, vacuum governor and fuel

return valve (284)

Line colors

bl = blue

br = brown

gr = grey

gn = green

rt = red

ws = white

|

||||

|

|

||||

|

1975/76,

|

||||

|

|

||||

|

A Vacuum connection check valve (35) of

vacuum booster for EGR B Vacuum connection for draw-off valve (38)

of fuel evaporation control system C Vacuum connection for check valve (35) of

float chamber vent system, vacuum governor

and fuel return valve (284)

Line colors

|

|

|||

|

bl = br =

|

blue brown

|

|||

|

gn = green

sw = black

vi = purple

ws = white

|

||||

|

|

||||

|

07.2.2 la-194/5

|

||||

|

|

||||

|

|

||||

|

1976

|

|

|||

|

A Vacuum connection 40 °C thermovalve (60) of EGR

B Vacuum connection for ignition advance

C Vacuum connection for vacuum governor

D Vacuum connection for vacuum booster (54) of EGR

Line colors

|

||||

|

br

ge

rt vi

|

brown yellow red purple

|

|||

|

|

||||

|

6 Adjust idle speed (07.2-100).

|

||||

|

|

||||

|

07.2.2 la-194/6

|

||||

|

|

||||

Nowsze