Checking fuel return valve

|

|

|||||

|

07.2—186 Checking fuel return valve

|

|||||

|

|

|||||

|

A. Without fuel pressure control

|

|||||

|

|

|||||

|

Special tool

|

|||||

|

|

|||||

|

Clamp

|

|

000 589 40 37 00

|

|||

|

|

|||||

|

Conventional tool

|

|||||

|

|

|||||

|

Pressure tester

|

|||||

|

|

|||||

|

Note

|

|||||

|

|

|||||

|

On a vacuum -controlled fuel return valve, with a leaking diaphragm, the fuel is drawn off by the intake pipe vacuum. The results are high fuel consumption and irregular idle running. It may not be possible to adjust the idle speed emission value.

|

|||||

|

|

|||||

|

Checking

|

|

||||

|

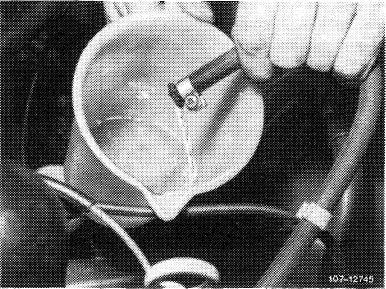

1 Pull fuel return hose from connection to return line. Hold fuel return hose into a container. Run engine, fuel should now come out of return hose in the shape of a jet.

On vehicles with air conditioning system and automatic transmission, engage driving position or switch on air conditioning system.

|

|||||

|

|

|||||

|

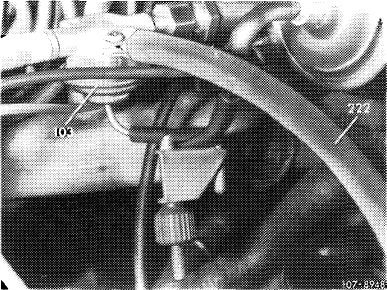

2 On fuel return valves without fuel pressure regulation (vacuum -controlled!), check diaphragm for leaks.

For this purpose, run engine at idle speed, pinch vacuum hose, idle speed emission value or idle speed should not change. Repiace return valve, if required.

|

|

||||

|

|

|||||

|

07.2.2 la—186/1

|

|||||

|

|

|||||

|

|

|||

|

B. With fuel pressure control ((£) 1976 only)

|

|||

|

|

|||

|

Test value

|

|||

|

|

|||

|

Fuel pressure (measured after fuel return valve)

|

approx. 0.2 bar gauge pressure

|

||

|

|

|||

|

Conventional tool

|

|||

|

|

|||

|

Pressure tester

|

|||

|

|

|||

|

Testing

|

|

||

|

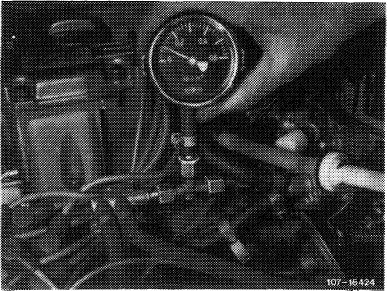

1 On fuel return valves with fuel pressure regulation (T) 1976, check function of pressure control.

For this purpose, connect pressure tester between return valve and carburetor. Run engine at idle and read regulated fuel pressure.

|

|||

|

|

|||

|

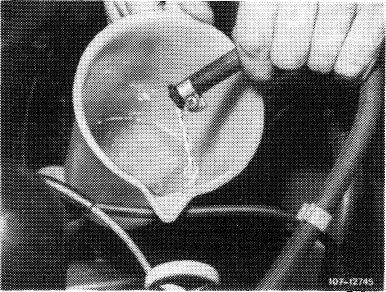

2 Pull off fuel return hose at connection for return line. Hold fuel return hose into a container. Run engine, fuel should now come out of return hose in the shape of a jet.

On vehicles with air conditioning system and automatic transmission, engage driving position or switch on air conditioning system.

|

|

||

|

|

|||

|

07.2.2 la-186/2

|

|||

|

|

|||

Nowsze