Replacing threaded bushing and valve adjusting screw

|

|

|||||||||||||||||||||||||||||||||||

|

05—212 Replacing threaded bushing and valve adjusting screw

|

|||||||||||||||||||||||||||||||||||

|

|

|||||||||||||||||||||||||||||||||||

|

Valve clearance

|

Cold engine (approx. 20 °C)

|

Warm engine (60 °C ± 15°C)

|

|||||||||||||||||||||||||||||||||

|

|

|||||||||||||||||||||||||||||||||||

|

Intake

|

0.101)

|

0.151)

|

|||||||||||||||||||||||||||||||||

|

|

|||||||||||||||||||||||||||||||||||

|

Exhaust

|

0.25

|

0.30

|

|||||||||||||||||||||||||||||||||

|

|

|||||||||||||||||||||||||||||||||||

|

0.05 mm more for consistent outside temperatures below —20 °C.

|

|||||||||||||||||||||||||||||||||||

|

|

|||||||||||||||||||||||||||||||||||

|

|||||||||||||||||||||||||||||||||||

|

|

|||||||||||||||||||||||||||||||||||

|

Depressor for valve spring

|

|

110 589 04 61 00

|

|||||||||||||||||||||||||||||||||

|

|

|||||||||||||||||||||||||||||||||||

|

cm

|

|||||||||||||||||||||||||||||||||||

|

Valve adjusting wrench 17 mm, 1/2″ square, for checking torque of adjusting screw

|

|

110 589 00 01 00

|

|||||||||||||||||||||||||||||||||

|

OS

|

|||||||||||||||||||||||||||||||||||

|

|

|||||||||||||||||||||||||||||||||||

|

Valve adjusting wrench 17 mm

|

11004-7003

|

110 589 01 01 00

|

|||||||||||||||||||||||||||||||||

|

|

|||||||||||||||||||||||||||||||||||

|

Contact grip to turn engine (part of compression recorder 001 589 46 21 00)

|

|

001 589 46 21 08

|

|||||||||||||||||||||||||||||||||

|

|

|||||||||||||||||||||||||||||||||||

|

05.2-212/1 F3

|

|||||||||||||||||||||||||||||||||||

|

|

|||||||||||||||||||||||||||||||||||

|

|

|||

|

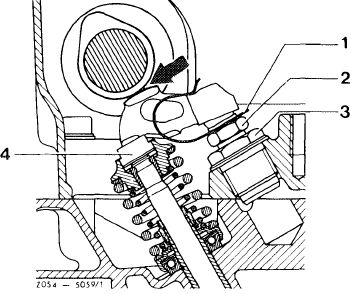

Note

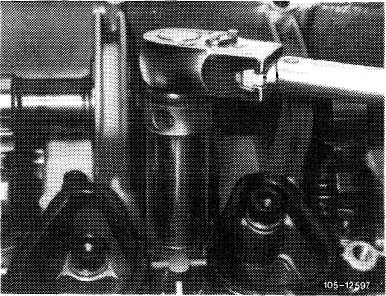

If torque of valve adjusting screw is less than 20 Nm (2 kpm), replace valve adjusting screw (2) or threaded bushing (3) with valve adjusting screw (2).

|

|

||

|

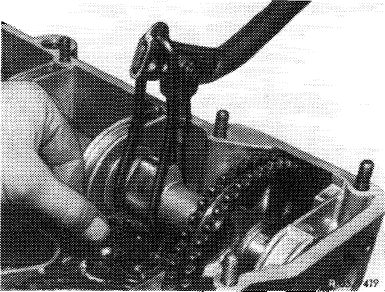

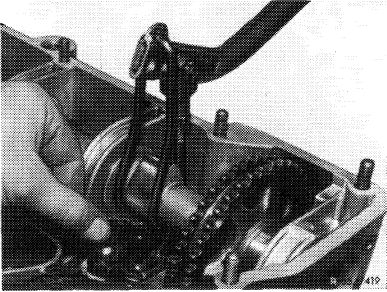

1 Spring clamp

2 Valve adjusting screw

3 Threaded bushing

4 Pressure pad

|

|||

|

|

|||

|

The torque can be checked with a valve adjusting wrench, part number 110 589 00 01 00 and a torque wrench (e. g. part number 000 589 27 21).

|

|

||

|

|

|||

|

Replacing

|

|

||

|

1 Remove rocker arms (05—230).

|

|||

|

|

|||

|

2 Unscrew threaded bushing with valve adjusting screw.

|

|

||

|

|

|||

|

05.2-212/2

|

|||

|

|

|||

|

|

|||

|

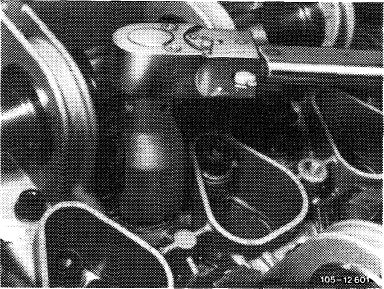

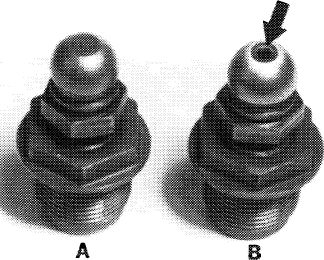

Attention!

Only use valve adjusting screws with an oil bore (arrow).

3 Coat threads of threaded bushing with valve adjusting screw with tallow, install and tighten threaded bushing to a torque of 80 Nm (8 kpm).

Attention!

Threaded bushing must be free of burrs when installing, since these would find their way into the oil circuit.

|

|

||

|

|

|||

|

105-12453

|

|||

|

|

|||

|

4 Install rocker arms (05-230).

|

|

||

|

|

|||

|

5 Adjust valve clearance (05—210).

|

V. 7

|

||

|

|

|||

|

05.2-212/3

|

|||

|

|

|||