Repairing and squaring connecting rods

|

|

||||||||||||||||||||||||||||||||||||||||||||||||

|

03—313 Repairing and squaring connecting rods

|

||||||||||||||||||||||||||||||||||||||||||||||||

|

|

||||||||||||||||||||||||||||||||||||||||||||||||

|

Data

|

||||||||||||||||||||||||||||||||||||||||||||||||

|

|

||||||||||||||||||||||||||||||||||||||||||||||||

|

||||||||||||||||||||||||||||||||||||||||||||||||

|

|

||||||||||||||||||||||||||||||||||||||||||||||||

|

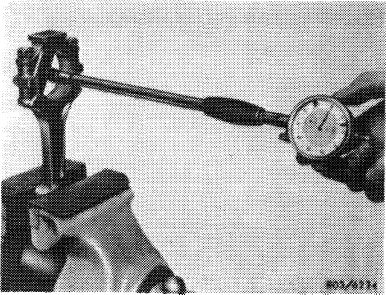

Permissible difference in parallel between axes: conrod bearing bore to conrod bushing bore in reference to a length of 100 mm

|

dia. 0.015

|

|||||||||||||||||||||||||||||||||||||||||||||||

|

|

||||||||||||||||||||||||||||||||||||||||||||||||

|

||||||||||||||||||||||||||||||||||||||||||||||||

|

|

||||||||||||||||||||||||||||||||||||||||||||||||

|

03.2-313/1 F3

|

||||||||||||||||||||||||||||||||||||||||||||||||

|

|

||||||||||||||||||||||||||||||||||||||||||||||||

|

|

|||

|

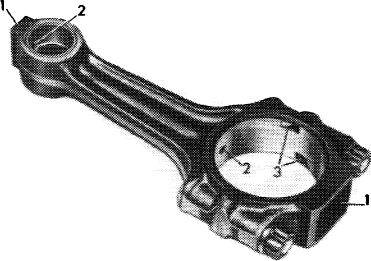

Note

Connecting rods, which are overheated (blue discoloration) due to bearing damage, may not be re-used.

The connecting rod and its cap are marked to fit together. The connecting rod stem must not show cross scoring and notches.

Connecting rods with a machined conrod bushing are delivered as replacement parts.

When renewing conrods pay attention to different weights of rods.

|

|

||

|

|

|||

|

Repairing

|

|

||

|

1 Check conrod bolts and replace if necessary (03-310).

|

|||

|

|

|||

|

2 Check conrod bolt bores.

|

|||

|

|

|||

|

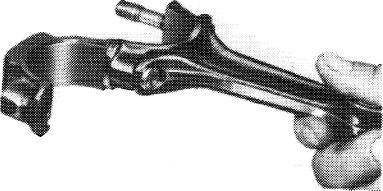

Place conrod cap on a conrod bolt. If the conrod cap moves down by its own weight, the connecting rod must be replaced.

|

|

||

|

|

|||

|

3 Mount connecting rod bearing cap and tighten to 40-50 Nm and 90-100° angle of rotation torque.

|

|

||

|

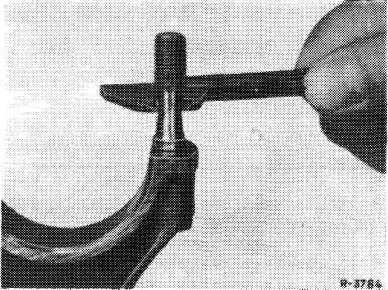

4 Measure conrod bearing basic bore. If a basic bore exceeds the value of 51.62 mm or shows conicity, hone bearing surface of bearing cap on a surface plate up to max. 0.02 mm.

|

|||

|

|

|||

|

03.2-313/2 F3

|

|||

|

|

|||

|

|

|||||

|

5 Press in new conrod bushing that oil bores match. Installation pressure 2500 Nm.

6 Mill or ream out conrod bushing.

7 Hone side bearing surfaces of connecting rod on a surface plate.

|

|

||||

|

|

|||||

|

Squaring

|

|||||

|

|

|||||

|

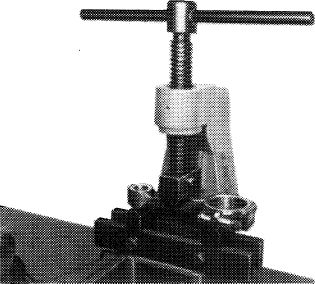

8 Square connecting rod with a conrod tester.

|

|||||

|

|

|||||

|

9 Align parallel of conrod bore to conrod bushing bore.

|

|

103-11174

|

|||

|

|

|||||

|

10 Correct stagger of conrod bore to conrod bushing bore.

|

|

-11173

|

|||

|

|

|||||

|

03.2-313/3 F3

|

|||||

|

|

|||||