Removal and installation of intermediate wheel

|

|

||||||||||||||||||||||||||||||||||||||||||||

|

05—432 Removal and installation of intermediate wheel

|

||||||||||||||||||||||||||||||||||||||||||||

|

|

||||||||||||||||||||||||||||||||||||||||||||

|

||||||||||||||||||||||||||||||||||||||||||||

|

|

||||||||||||||||||||||||||||||||||||||||||||

|

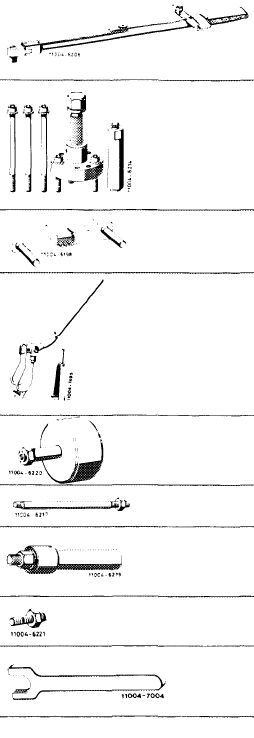

Torque wrench single-arm, 3/4″ square, 150-500 Nm

|

|

001 589 31 21 00

|

||||||||||||||||||||||||||||||||||||||||||

|

Balance disc extractor

|

116 589 10 33 00

|

|||||||||||||||||||||||||||||||||||||||||||

|

Holder

|

110 589 00 40 00

|

|||||||||||||||||||||||||||||||||||||||||||

|

Depressor for valve spring

|

110 589 04 61 00

|

|||||||||||||||||||||||||||||||||||||||||||

|

Impact extractor for bearing pin (basic unit)

|

116 580 20 33 00

|

|||||||||||||||||||||||||||||||||||||||||||

|

Threaded bolt M 8 x 150 long (for impact puller)

|

616 589 00 34 00

|

|||||||||||||||||||||||||||||||||||||||||||

|

Puller for bearing bolt (basic unit)

|

115 589 20 33 00

|

|||||||||||||||||||||||||||||||||||||||||||

|

M 8 x 30 bolt for extractor

|

115 589 00 34 00

|

|||||||||||||||||||||||||||||||||||||||||||

|

Camshaft holding wrench

|

116 589 01 01 00

|

|||||||||||||||||||||||||||||||||||||||||||

|

|

||||||||||||||||||||||||||||||||||||||||||||

|

05.2-432/1 F3

|

||||||||||||||||||||||||||||||||||||||||||||

|

|

||||||||||||||||||||||||||||||||||||||||||||

|

|

||||||||||||||||||||||||||||||||||||

|

Valve adjusting wrench 17 mm

|

|

110 589 01 01 00

|

||||||||||||||||||||||||||||||||||

|

t1004 -7003

|

||||||||||||||||||||||||||||||||||||

|

|

||||||||||||||||||||||||||||||||||||

|

||||||||||||||||||||||||||||||||||||

|

|

||||||||||||||||||||||||||||||||||||

|

Removal

|

|

|||||||||||||||||||||||||||||||||||

|

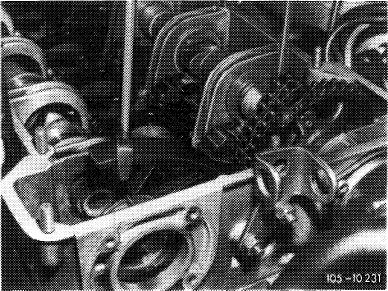

1 Remove radiator and fan.

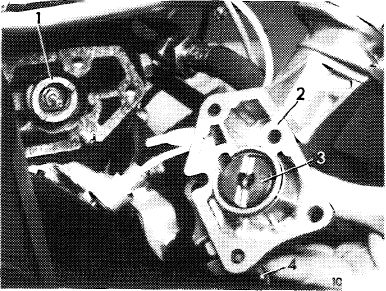

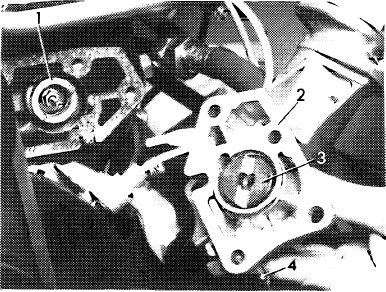

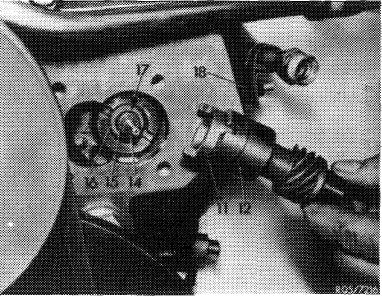

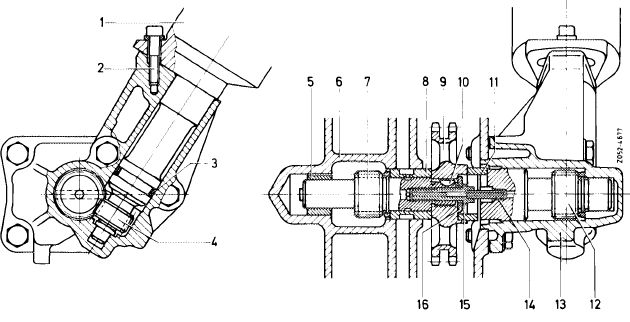

2 Remove oil pump drive helical gear shaft (4) (05-410).

|

||||||||||||||||||||||||||||||||||||

|

|

||||||||||||||||||||||||||||||||||||

|

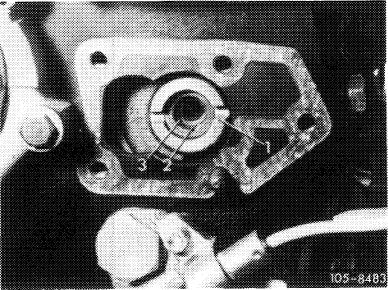

3 Remove distributor housing (2) with drive gear (3) for distributor drive (05—450).

|

■5 848′

|

|||||||||||||||||||||||||||||||||||

|

|

||||||||||||||||||||||||||||||||||||

|

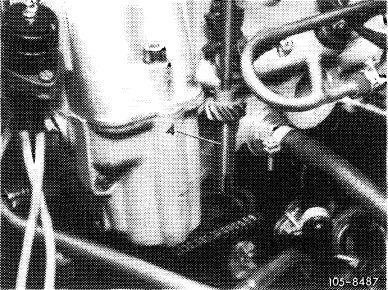

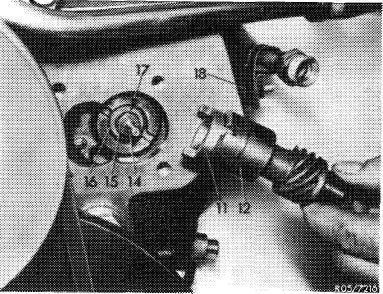

4 Remove bolt (15) with oil tube (14), lock washer (17) and washer (16).

5 Unscrew chain lock screw (18).

|

|

|||||||||||||||||||||||||||||||||||

|

|

||||||||||||||||||||||||||||||||||||

|

05.2-432/2 F3

|

||||||||||||||||||||||||||||||||||||

|

|

||||||||||||||||||||||||||||||||||||

|

|

|||

|

6 Remove tensioning rail (05—330).

|

|

||

|

|

|||

|

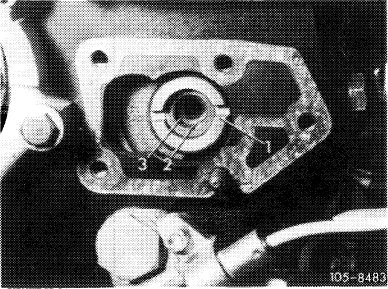

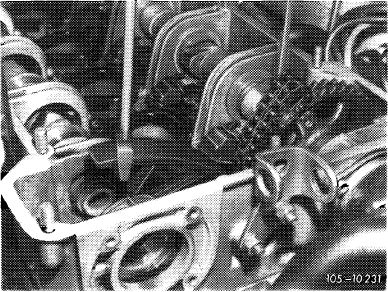

7 Turn intermediate wheel shaft (3) until woodruff key (2) is up.

8 Press back intermediate wheel shaft (3) until intermediate wheel (1) can be removed upward. Watch woodruff key.

|

|

||

|

Installation

|

|||

|

9 Guide intermediate wheel into chain case and install on intermediate wheel shaft.

|

|||

|

|

|||

|

|||

|

|

|||

|

10 Pull intermediate wheel shaft (3) forward carefully with a M 8 bolt and at the same time turn intermediate wheel (1) until woodruff key (2) slides into groove of intermediate wheel.

|

|

||

|

|

|||

|

05.2-432/3

|

|||

|

|

|||

|

|

|||

|

11 Install bolt (15) with oil tube (14), lock washer (17) and washer (16), and torque to 25 Nm.

Install chain lock screw (18).

|

|

||

|

|

|||

|

12 Install distributor housing with drive gear for distributor drive (05—450).

|

105-8481

|

||

|

|

|||

|

13 Install tensioning rail (05-330).

|

|

||

|

|

|||

|

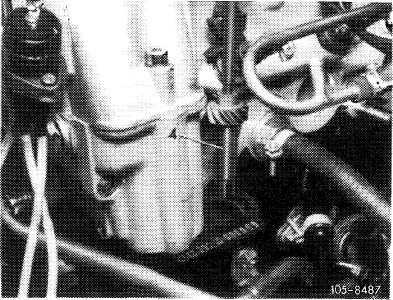

14 Install helical gear shaft for oil pump drive (05-410).

15 Install radiator and fan.

|

|

||

|

|

|||

|

05.2-432/4 F3

|

|||

|

|

|||