Removal and installation of idle speed shutoff valves

|

|

||||||

|

07.2—104 Removal and installation of idle speed shutoff valves

|

||||||

|

|

||||||

|

Tightening torques

|

Nm

|

(kpm)

|

||||

|

|

||||||

|

with new insulating flange

|

10

|

(1.0)

|

||||

|

|

||||||

|

Carburetor fastening nuts

|

||||||

|

|

||||||

|

with insulating flange used up to now

|

8

|

(0.8)

|

||||

|

|

||||||

|

Special tool

|

||||||

|

|

||||||

|

Torque wrench 4—16 Nm (40—60 kpcm)

|

|

000 589 67 21 00

|

||||

|

I

|

||||||

|

|

||||||

|

Removal

|

|

|||||

|

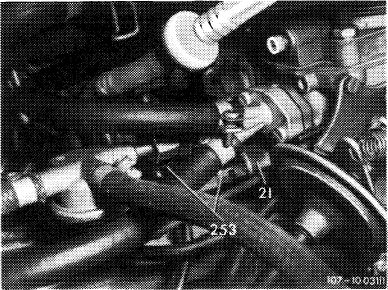

1 Remove carburetor (07.2-194).

|

||||||

|

2 Unscrew idle speed shutoff valves.

|

||||||

|

Installation

|

||||||

|

4 For installation proceed vice versa.

|

||||||

|

|

||||||

|

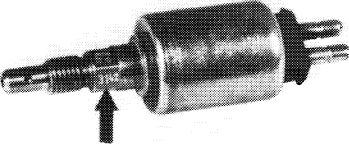

Starting August 1973 the shutoff voltage of the installed idle speed shutoff valves has been increased to 3.0 volts (formerly 0.5 volt). This will prevent afterrunning of engine. Subsequent installation is generally possible.

Identification: production code number 3 142 (arrow).

|

|

|||||

|

|

||||||

|

3 = Production year 1973 142 = Production day (consecutive calendar day)

|

¥)7-9\O7

|

|||||

|

|

||||||

|

07.2.2 la-104/1

|

||||||

|

|

||||||

Nowsze