Renewing and tensioning of V-belt

|

|

|||||||||||||||||||||||||||||||||||||||||||||||||||

|

13—340 Renewing and tensioning of V-belt

|

|||||||||||||||||||||||||||||||||||||||||||||||||||

|

|

|||||||||||||||||||||||||||||||||||||||||||||||||||

|

V-belt dimensions and adjusting values

|

|||||||||||||||||||||||||||||||||||||||||||||||||||

|

|

|||||||||||||||||||||||||||||||||||||||||||||||||||

|

|||||||||||||||||||||||||||||||||||||||||||||||||||

|

|

|||||||||||||||||||||||||||||||||||||||||||||||||||

|

l) Double V-belts may be installed in pairs and from one manufacturer only.

|

|||||||||||||||||||||||||||||||||||||||||||||||||||

|

|

|||||||||||||||||||||||||||||||||||||||||||||||||||

|

Conventional tool

|

|||||||||||||||||||||||||||||||||||||||||||||||||||

|

|

|||||||||||||||||||||||||||||||||||||||||||||||||||

|

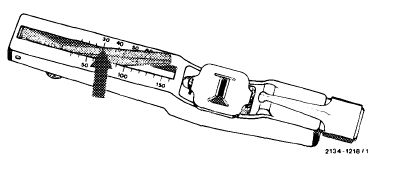

Measuring instrument (Krikit)

|

e.g. made by Gates GmbH

Gravener StraBe 191-193, D-4018 Langenfeld 2

e.g. made by Gates Rubber Company

999 S. Broadway, USA-80217 Denver/Colorado

|

||||||||||||||||||||||||||||||||||||||||||||||||||

|

|

|||||||||||||||||||||||||||||||||||||||||||||||||||

|

Note

|

|

||||||||||||||||||||||||||||||||||||||||||||||||||

|

The Krikit measuring instrument is recommended for testing V-belt tension.

|

|||||||||||||||||||||||||||||||||||||||||||||||||||

|

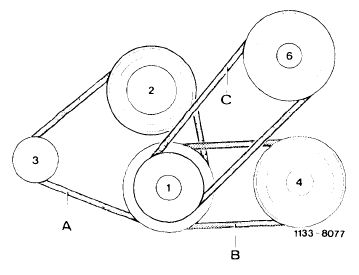

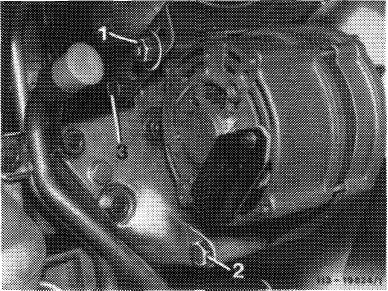

1 Crankshaft

2 Coolant pump

3 Alternator

|

4 Refrigerant compressor 6 Power steering pump

|

||||||||||||||||||||||||||||||||||||||||||||||||||

|

|

|||||||||||||||||||||||||||||||||||||||||||||||||||

|

Handling of measuring instrument

|

|

||||||||||||||||||||||||||||||||||||||||||||||||||

|

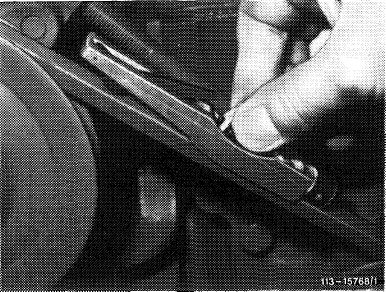

For testing V-belt tension the measuring instrument can be handled in various ways:

a) With thumb and forefinger against rubber loop, with the finger tips resting on pushbutton.

|

|||||||||||||||||||||||||||||||||||||||||||||||||||

|

|

|||||||||||||||||||||||||||||||||||||||||||||||||||

|

13.8-340/1 F 2

|

|||||||||||||||||||||||||||||||||||||||||||||||||||

|

|

|||||||||||||||||||||||||||||||||||||||||||||||||||

|

|

|||

|

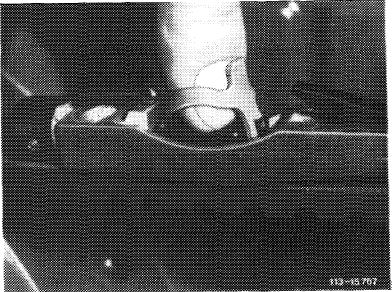

b) With forefinger from above in rubber loop.

|

|

||

|

|

|||

|

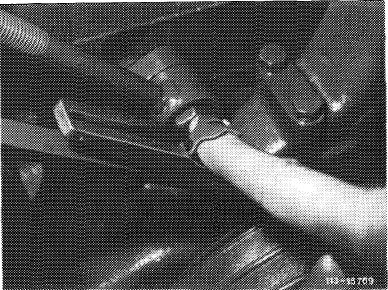

c) With forefinger laterally between rubber loop and pushbutton.

|

|

||

|

|

|||

|

Testing

|

|

||

|

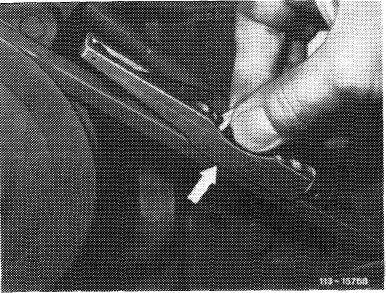

1 Lower indicator arm on measuring instrument.

2 Place measuring instrument on V-belt in center between pulleys. The lateral stop of the measuring instrument should rest laterally against V-belt (arrow).

Attention!

On double belt drive, make sure that the measuring instrument rests on one V-belt only.

|

|||

|

|

|||

|

3 Exert a uniform, vertical pressure on V-belt upper surface by means of pushbutton, until click spring is audibly (or noticeably) disengaging.

Note: Upon disengagement of click spring, do not continue pushing on measuring instrument, since otherwise a wrong measuring value will be indicated.

|

|||

|

|

|||

|

13.8-340/2 F 2

|

|||

|

|

|||

|

|

|||

|

4 Carefully lift measuring instrument from V-belt. Avoid knocks against instrument and do not change position of indicator arm.

5 Read tensioning value at point of intersection of indicator arm and upper scale (KG scale, arrow).

The respective adjusting values refer to upper scale of measuring instrument.

|

|

||

|

|

|||

|

Replacement

|

|||

|

|

|||

|

Check condition of V-belt

Replace cracked, porous, burnt or worn V-belts.

Attention!

If one of the two V-belts of double belt drive for alternator and coolant pump fails due to wear, always replace both V-belts on principle.

Use only V-belts in pairs made by one and the same manufacturer.

V-belts are available as spare parts in sets only.

|

|||

|

|

|||

|

1 Move tensioning device or units into starting position.

2 Mount V-belt without using force.

3 Tension V-belt.

|

|||

|

|

|||

|

Tensioning

|

|

||

|

V-belt A Alternator — coolant pump

|

|||

|

1 Loosen nut (1) and screws (2 and 3).

|

|||

|

|

|||

|

13.8-340/3 F2

|

|||

|

|

|||

|

|

|||

|

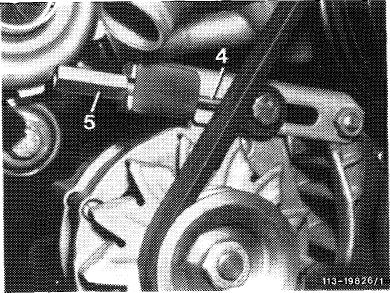

2 Tension V-belt by means of nut (5) of tensioning screw (4).

3 Tighten nut (1) and screws (2 and 3).

4 Continue turning nut (5) by approx. 1 /4 to 1 /2 turn (to tight seat).

|

|

||

|

|

|||

|

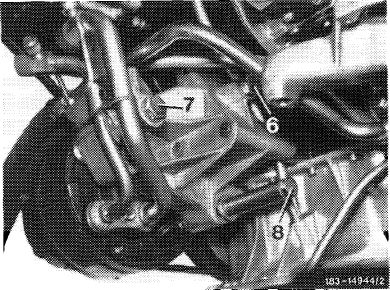

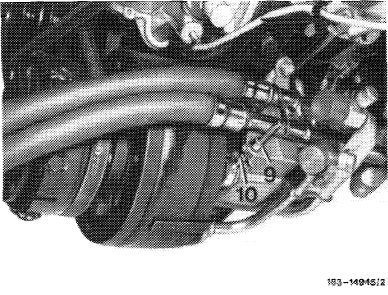

V-belt B Refrigerant compressor

|

|

||

|

1 Loosen screws (6, 7 and 8).

|

|||

|

|

|||

|

2 Tension V-belt by means of nut (9) of tensioning screw (10).

3 Tighten screws (6, 7 and 8).

|

|

||

|

|

|||

|

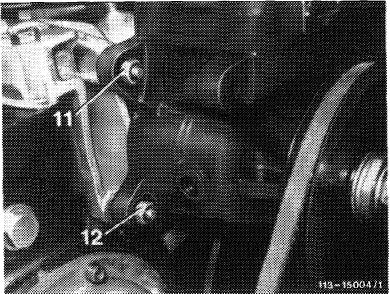

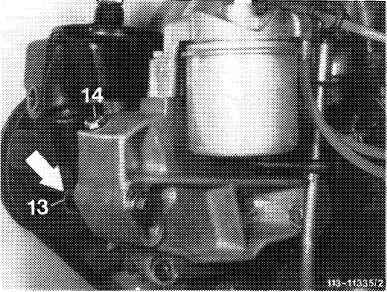

V-belt C Power steering pump

|

|

||

|

1 Loosen nuts (11, 12 and 13).

|

|||

|

|

|||

|

13.8-340/4- F2

|

|||

|

|

|||

|

|

|||

|

2 Tension V-belt by means of tensioning screw (14).

|

|

||

|

3 Tighten nuts (11, 12 and 13).

|

|||

|

|

|||

|

13.8-340/5 F 2

|

|||

|

|

|||