Removal and installation of oil pump

|

|

||||||||||||||||||||||||

|

18—210 Removal and installation of oil pump

|

||||||||||||||||||||||||

|

|

||||||||||||||||||||||||

|

Tightening torques

|

Nm

|

|||||||||||||||||||||||

|

|

||||||||||||||||||||||||

|

Oil drain plug to oil pan

|

35-45

|

|||||||||||||||||||||||

|

|

||||||||||||||||||||||||

|

M6

|

9-11

|

|||||||||||||||||||||||

|

|

||||||||||||||||||||||||

|

Oil pan upper half to cylinder crankcase

|

||||||||||||||||||||||||

|

|

||||||||||||||||||||||||

|

M8

|

20-25

|

|||||||||||||||||||||||

|

|

||||||||||||||||||||||||

|

Oil pan lower half to upper half

|

9-11

|

|||||||||||||||||||||||

|

|

||||||||||||||||||||||||

|

Engine carrier to engine mount front

|

70

|

|||||||||||||||||||||||

|

|

||||||||||||||||||||||||

|

to crankcase

|

20-25

|

|||||||||||||||||||||||

|

|

||||||||||||||||||||||||

|

Oil pump

|

||||||||||||||||||||||||

|

|

||||||||||||||||||||||||

|

||||||||||||||||||||||||

|

|

||||||||||||||||||||||||

|

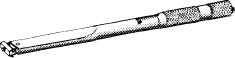

Torque wrench handle 20—100 Nm

|

11004-7035

|

001 589 35 21 00

|

||||||||||||||||||||||

|

Torque wrench handle 50—200 Nm

|

001 589 44 21 00

|

|||||||||||||||||||||||

|

|

||||||||||||||||||||||||

|

Changeover ratchet for torque wrench

|

|

001 589 42 09 00

|

||||||||||||||||||||||

|

|

||||||||||||||||||||||||

|

Allen wrench 5 mm, 300 mm long

|

|

116 589 02 07 00

|

||||||||||||||||||||||

|

Knock-out mandrel 9 mm dia.

Socket 27 mm, 1/2″ square for rotating engine

Knock-in tool for oil dipstick guide tube

Conventional tool

Engine hoist (Motordirigent) size 1.5

|

110 589 02 15 00 001 589 65 09 00

117 589 00 31 00

|

|||||||||||||||||||||||

|

e.g. made by Backer, D—5630 Remscheid Order No. 3178

|

||||||||||||||||||||||||

|

|

||||||||||||||||||||||||

|

18.8-210/1 F2

|

||||||||||||||||||||||||

|

|

||||||||||||||||||||||||

|

|

|||

|

Note

Since a connecting link might wipe against timing chain or oil pan, do not open double roller chain during repairs and connect again by means of a connecting link.

To renew double roller chain and tensioning unit, completely remove oil pan (01—310) and front cylinder housing cover (01—107).

|

|||

|

|

|||

|

Removal

|

|

||

|

1 Completely remove oil pan (01—310).

2 Unscrew fastening screw (56) of sprocket.

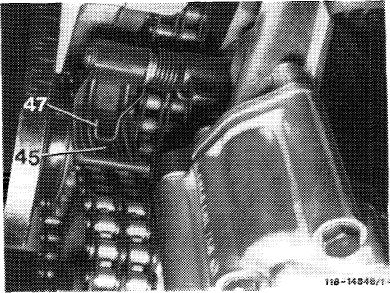

3 Remove torsion spring (47) from clamp (45) in rearward direction.

4 Turn clamp in upward direction.

|

|||

|

45 Clamp

47 Torsion spring

|

|||

|

|

|||

|

5 Remove sprocket by means of two screwdrivers.

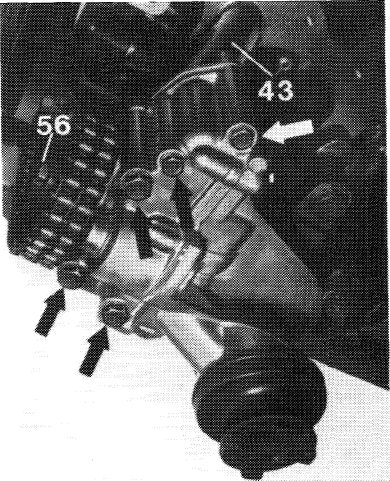

6 Unscrew hex. screws (arrows) on oil pump and remove oil pump.

7 Remove sprocket.

8 Pull flange member (43) out of cylinder crankcase.

|

|

||

|

43 Flange member 56 Fastening screw

|

|||

|

US -148&1

|

|||

|

|

|||

|

18.8-210/2 F 2

|

|||

|

|

|||

|

|

|||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|

Installation

|

|||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|

|

|||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|

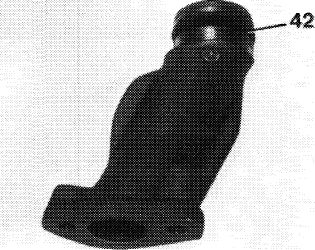

9 Renew O-ring (42) on flange member, if damaged.

10 Insert flange member.

11 Place sprocket into double roller chain.

12 Install oil pump and tighten fastening screws to 20—25 Nm on crankcase or 9—11 Nm on flange member.

42 O-ring

|

|

||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|

|

|||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|

13 Place sprocket on drive shaft and tighten fastening screw (56) to 30-35 Nm.

14 Set clamp on double roller chain and place torsion spring on clamp.

15 Completely install oil pan (01-310).

|

|||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|

|

|||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|

Layout of oil pump

|

|||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|

|

|||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|

|||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|

|

|||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|

|||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|

|

|||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||