Removal and installation of injection nozzles

|

|

|||||

|

07.1—230 Removal and installation of injection nozzles

|

|||||

|

|

|||||

|

Job no. of flat rates or standard texts and flat rates data 07—6810 or 6830.

|

|||||

|

|

|||||

|

Tightening torques

|

Nm

|

||||

|

|

|||||

|

Injection nozzles

|

70-80

|

||||

|

|

|||||

|

Injection lines

|

25

|

||||

|

|

|||||

|

Special tools

|

|||||

|

|

|||||

|

Box wrench socket open, 17 mm, 1/2″ drive for injection lines

|

|

000 589 68 03 00

|

|||

|

|

|||||

|

Socket for injection nozzle 27 mm, 1/2″ drive

|

|

001 589 65 09 00

|

|||

|

|

|||||

|

Conventional tools

|

|||||

|

|

|||||

|

Torque wrench 1/2″ drive, 40-130 Nm

|

|||||

|

|

|||||

|

Torque wrench 1/2″ drive, 15—65 Nm

|

|||||

|

|

|||||

|

Removal

|

|||||

|

|

|||||

|

1 Unscrew injection lines.

2 Detach leak-off fuel hoses and plug of 5th injection nozzle.

3 Unscrew injection nozzles using socket. If precombustion chamber collar comes undone, tighten all collars (05-117).

4 Withdraw nozzle plate (53).

5 Sight-check precombustion chamber. Direct flashlight into chamber and examine whether ball pin is in satisfactory condition.

|

|

||||

|

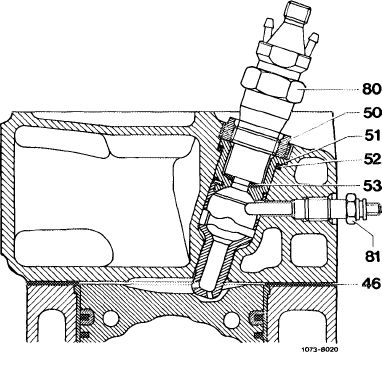

46 Cylinder head gasket 53 Nozzle plate

50 Collar 80 Injection nozzle

51 Precombustion chamber 81 Pin-type glow plug

52 Sealing ring

|

|||||

|

|

|||||

|

Installation

|

|||||

|

|

|||||

|

6 Install in reverse order, using new nozzle plates. Note tightening torques.

|

|||||

|

|

|||||

|

07.1.8-230/1 F3

|

|||||

|

|

|||||