Removal and installation of oil pump

|

|

|||||||||||||||||||||||||||||||||||

|

18—210 Removal and installation of oil pump

|

|||||||||||||||||||||||||||||||||||

|

|

|||||||||||||||||||||||||||||||||||

|

|||||||||||||||||||||||||||||||||||

|

|

|||||||||||||||||||||||||||||||||||

|

Note

|

|

||||||||||||||||||||||||||||||||||

|

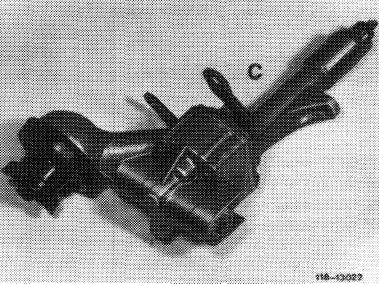

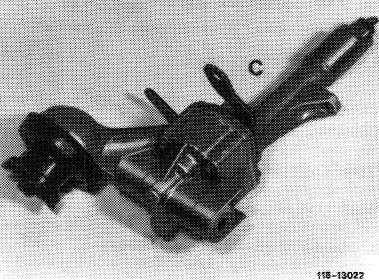

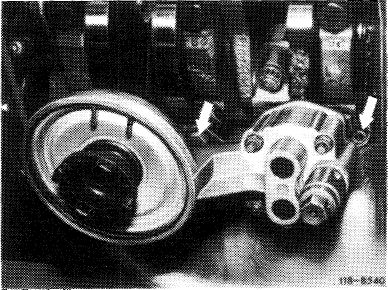

In the event of repairs or when installing an oil pump drive, part no. 110 050 02 06, install oil pump, part no. 110 180 27 01 (version C).

This oil pump has a strainer of 60 mm dia. and two screwed-on holders. Install pump only in combination with a 5-bar pressure relief valve in main oil duct (18-020).

|

|||||||||||||||||||||||||||||||||||

|

Version C

|

|||||||||||||||||||||||||||||||||||

|

|

|||||||||||||||||||||||||||||||||||

|

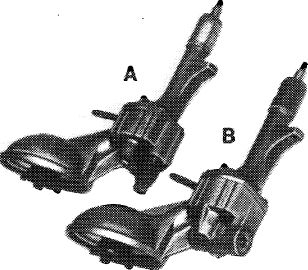

Oil pumps (version A and B) used up to now are provided with a strainer of 110 mm dia. and one screwed-on holder.

|

|||||||||||||||||||||||||||||||||||

|

|

|||||||||||||||||||||||||||||||||||

|

Version A and B

|

118-12585

|

||||||||||||||||||||||||||||||||||

|

|

|||||||||||||||||||||||||||||||||||

|

18.2-210/1 F3

|

|||||||||||||||||||||||||||||||||||

|

|

|||||||||||||||||||||||||||||||||||

|

|

||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|

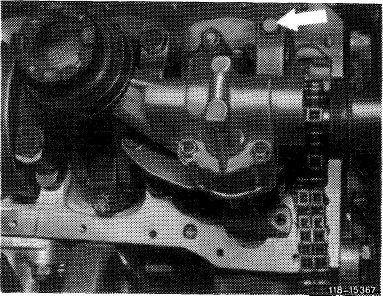

Standard installation oil pump version C

|

|

|||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|

||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|

|

||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|

All exchange engines starting unit no. 464130 are provided with oil pump version C with 60 mm dia. strainer.

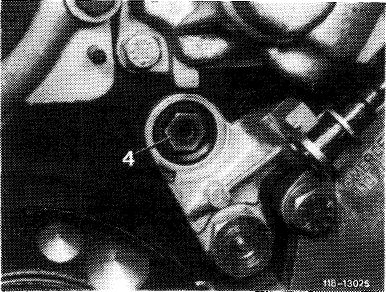

Install oil pump version C only in combination with a 5-bar pressure relief valve in main oil duct (4) (18-020).

Note: Standard installation for carburetor engines is oil pump 110 180 27 01 with a drive cam for fuel pump, and for injection engines oil pump 110 180 26 01 without drive cam.

As a spare part, only oil pump 110 180 27 01 with drive cam will be supplied.

For subsequent installation of oil pump 110 180 27 01 mount a crankshaft bearing bolt 108 011 00 71 with internal threads for additional holder (arrow) on 1st crankshaft bearing cap and tighten to 80 Nm.

|

|

|||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|

||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|

|

||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|

18.2-210/2 F3

|

||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|

|

||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|

|

||||||||||||||||||||||||||||||||||||||||||||||||

|

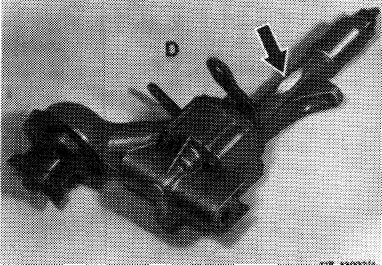

To save space, the oil pump has been modified by means of an additional weight on crankshaft. The pump has a recess (arrow) on housing shaft, to provide enough distance between crankshaft and oil pump.

When changing the oil pump, check whether a crankshaft with additional weight is installed. If yes, install only modified oil pump, part no. 110 180 33 01 for injection engines or 110 180 32 01 for carburetor engines with recess in housing shaft.

Standard application

|

|

|||||||||||||||||||||||||||||||||||||||||||||||

|

|

||||||||||||||||||||||||||||||||||||||||||||||||

|

Model

|

starting chassis end no.

|

|||||||||||||||||||||||||||||||||||||||||||||||

|

|

||||||||||||||||||||||||||||||||||||||||||||||||

|

||||||||||||||||||||||||||||||||||||||||||||||||

|

|

||||||||||||||||||||||||||||||||||||||||||||||||

|

Removal

|

|

|||||||||||||||||||||||||||||||||||||||||||||||

|

1 Remove fuel pump of carburetor engine.

2 Take off oil pan lower section.

3 Unscrew mounting bolt on crankcase and bearing cap.

4 Pull out oil pump.

|

||||||||||||||||||||||||||||||||||||||||||||||||

|

|

||||||||||||||||||||||||||||||||||||||||||||||||

|

Installation

|

||||||||||||||||||||||||||||||||||||||||||||||||

|

|

||||||||||||||||||||||||||||||||||||||||||||||||

|

5 For installation proceed vice versa.

|

||||||||||||||||||||||||||||||||||||||||||||||||

|

|

||||||||||||||||||||||||||||||||||||||||||||||||

|

6 Correct oil level and check engine for leaks.

|

||||||||||||||||||||||||||||||||||||||||||||||||

|

|

||||||||||||||||||||||||||||||||||||||||||||||||

|

18.2-210/3 F3

|

||||||||||||||||||||||||||||||||||||||||||||||||

|

|

||||||||||||||||||||||||||||||||||||||||||||||||