Adjusting accelerating pump

|

|

||||

|

07.2—150 Adjusting accelerating pump

|

||||

|

|

||||

|

Testing and adjusting values

|

||||

|

|

||||

|

Begin of injection

|

immediately

|

|||

|

|

||||

|

Special tool

|

||||

|

|

||||

|

Clamp

|

|

000 589 40 37 00

|

||

|

|

||||

|

Note

|

||||

|

|

||||

|

Perfect functioning of accelerating pump as well as accurate adjustment of pump are absolutely necessary for perfect starting or bypass characteristics. Starting and bypass faults may be caused by a wrong direction of injection jet, the jet should not touch neither the pre-atomizer nor the edge of the Venturi. Unless otherwise specified, injection should begin immediately. If the injected quantity is too low, bypass faults may occur in stage I and from stage I — II (stage jump).

|

||||

|

|

||||

|

Testing, adjusting

|

|

|||

|

a) Begin of injection

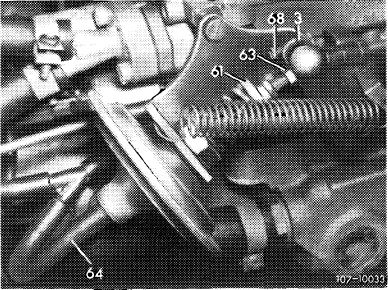

1 Keep engine running. Pinch vacuum hose (64), shut off engine.

2 Check whether throttle valve lever (3) is resting against idle speed adjusting screw (68) and adjust vacuum governor, if required.

|

||||

|

|

||||

|

07.2.2 la-150/1

|

||||

|

|

||||

|

|

|||

|

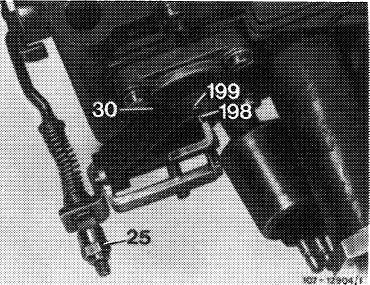

3 Set adjusting nut (25) in such a manner that the actuating lever (198) depresses the diaphragm pressure pin (199) by 1.0 mm.

Note: If no self-locking polystop adjusting nut (25) is installed, secure adjusting nut following adjustment by compressing (pinching) nut.

|

|

||

|

|

|||

|

b) Operation and direction of injection

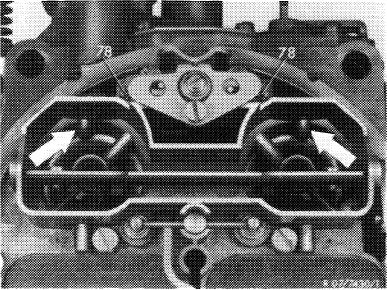

4 For this purpose, slowly actuate throttle valve lever, so that a uniform fuel jet will come out of both injection bores (arrows) immediately and on both sides.

Attention!

The fuel jet should not touch edge of Venturi and pre-atomizer, since this may result in starting and bypass faults. If required, remove carburetor cover and clean injection bores.

|

|

||

|

|

|||

|

07.2.2 la-150/2

|

|||

|

|

|||