Replacing ring gear

|

|

|||||||||||||||||||||||||||||||||||

|

03—430 Replacing ring gear

|

|||||||||||||||||||||||||||||||||||

|

|

|||||||||||||||||||||||||||||||||||

|

|||||||||||||||||||||||||||||||||||

|

|

|||||||||||||||||||||||||||||||||||

|

Temperature measuring chalk for 220°C

|

e.g. made by AW Faber-Castell

D-8504 Stein bei Niirnberg

Color no. 2815/220 (white) thermochrome

|

||||||||||||||||||||||||||||||||||

|

|

|||||||||||||||||||||||||||||||||||

|

Note

|

|||||||||||||||||||||||||||||||||||

|

|

|||||||||||||||||||||||||||||||||||

|

The ring gear is hardened. To protect hardened structure a max temperature of 250 °C should never be exceeded at any point when heating ring gear. Heating can be reliably done by means of a hot plate or a heating furnace only.

A flame may be used as an exception only. Flame should cover inside of ring gear only.

Following replacement of ring gear, no balancing of flywheel is required.

Only ring gears with chamfered teeth are supplied as spare parts.

These ring gears can also be installed on vehicles with manual transmission in place of ring gears without chamfer.

|

|||||||||||||||||||||||||||||||||||

|

|

|||||||||||||||||||||||||||||||||||

|

03.2-430/1 F 3

|

|||||||||||||||||||||||||||||||||||

|

|

|||||||||||||||||||||||||||||||||||

|

|

|||

|

Replacement

|

|

||

|

1 Drill into old ring gear and break up with a chisel, or heat quickly and then remove immediately.

2 Clean contact surface of ring gear on flywheel.

3 Uniformly heat new ring gear on a hot plate or in a heating furnace.

For this purpose, use temperature measuring chalk according to instructions.

4 Fit heated ring gear immediately on flywheel.

Attention!

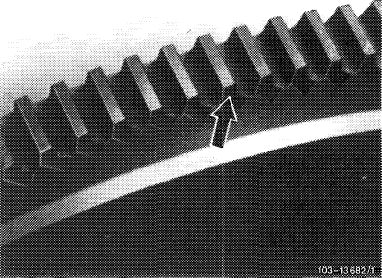

The tooth chamfer (arrow) should face starting motor.

|

|||

|

|

|||

|

03.2-430/2 F 3

|

|||

|

|

|||

Poprzedni

Machining flywheel

Nowsze