Removal and installation of pulley, vibration damper and balancing disc

|

|

|||||||||||||||||||||||||||||||||||||||||||||||||

|

03—340 Removal and installation of pulley, vibration damper and balancing disc

|

|||||||||||||||||||||||||||||||||||||||||||||||||

|

|

|||||||||||||||||||||||||||||||||||||||||||||||||

|

|||||||||||||||||||||||||||||||||||||||||||||||||

|

|

|||||||||||||||||||||||||||||||||||||||||||||||||

|

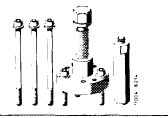

Torque wrench 150—500 IMm (15—50 kpm), 3/4″ square

|

|

001 589 31 21 00

|

|||||||||||||||||||||||||||||||||||||||||||||||

|

|

|||||||||||||||||||||||||||||||||||||||||||||||||

|

Detent

|

|

110 589 00 40 00 or

|

|||||||||||||||||||||||||||||||||||||||||||||||

|

|

|||||||||||||||||||||||||||||||||||||||||||||||||

|

Detent

|

|

116 589 01 40 00

|

|||||||||||||||||||||||||||||||||||||||||||||||

|

|

|||||||||||||||||||||||||||||||||||||||||||||||||

|

Puller for balancing disc

|

|

116 589 10 33 00

|

|||||||||||||||||||||||||||||||||||||||||||||||

|

|

|||||||||||||||||||||||||||||||||||||||||||||||||

|

Note

|

|

||||||||||||||||||||||||||||||||||||||||||||||||

|

The vibration damper can be replaced without balancing.

If the balancing disc is renewed, static balancing is required (03—344).

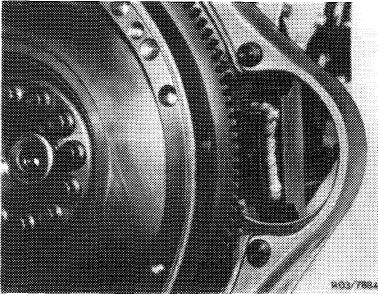

Since May 1974 a balancing disc with 3 cutouts for removing tensioning rail bearing bolt is installed.

|

|||||||||||||||||||||||||||||||||||||||||||||||||

|

|||||||||||||||||||||||||||||||||||||||||||||||||

|

|

|||||||||||||||||||||||||||||||||||||||||||||||||

|

03.2-340/1 F 3

|

|||||||||||||||||||||||||||||||||||||||||||||||||

|

|

|||||||||||||||||||||||||||||||||||||||||||||||||

|

|

|||

|

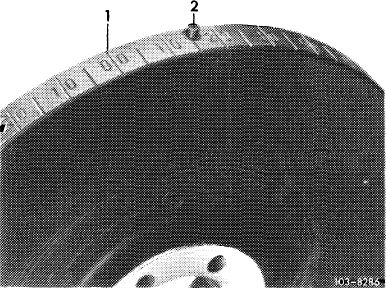

Attention!

For engines which have a “0/0” mark for BDC on the vibration damper besides TDC, the TDC mark in the vibration damper is next to the pin.

|

|

||

|

|

|||

|

Removal

|

|

||

|

1 Remove radiator and fan.

|

|||

|

2 Remove pulley and vibration damper.

|

|||

|

|

|||

|

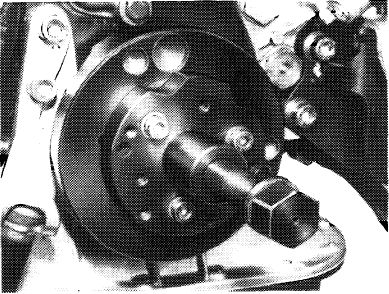

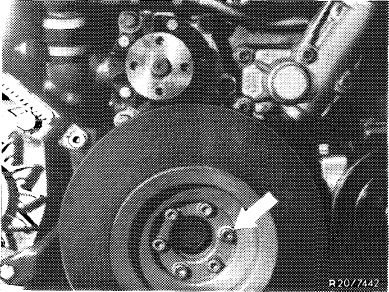

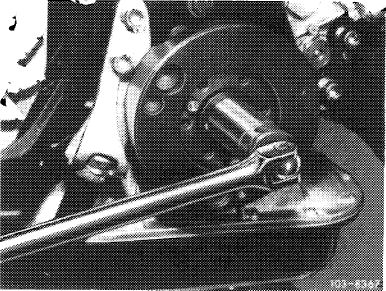

3 Counterhold crankshaft with holder.

|

|

||

|

|

|||

|

Holder 110 589 00 40 00

|

103-9243

|

||

|

|

|||

|

Also remove starter of engines with a manual transmission.

|

|

||

|

Holder 116 589 01 40 00

|

|||

|

|

|||

|

03.2-340/2

|

|||

|

|

|||

|

|

|||

|

4 Remove bolt in crankshaft.

|

|

||

|

|

|||

|

5 Mark balance disc and crankshaft together with a punch mark.

|

|

||

|

|

|||

|

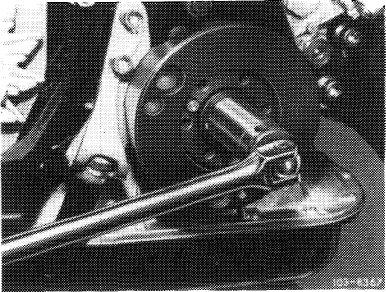

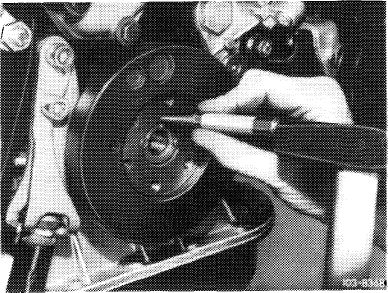

6 Pull off balance disc with an extractor.

|

103-8363

|

||

|

|

|||

|

Installation

|

|||

|

|

|||

|

7 Install balance disc on crankshaft that bores for dowel pins align.

Note: The balance disc is located on the crankshaft by two offset dowel pins.

|

|||

|

|

|||

|

03.2-340/3

|

|||

|

|

|||

|

|

|||||||||||||||||||||||||||||||

|

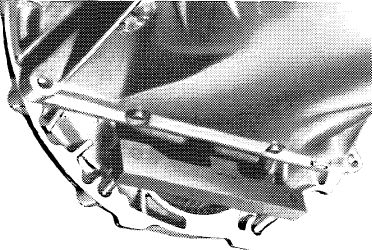

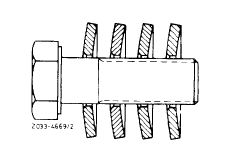

8 Pull balancing disc on crankshaft with screw M 18 x 1.5 x 45 and a cup spring.

9 Knock-in both set pins.

|

|

||||||||||||||||||||||||||||||

|

|

|||||||||||||||||||||||||||||||

|

10 Mount four cup springs with convex face facing screw head.

11 Tighten screw on crankshaft to 400 Nm

while applying counterhold to crankshaft by means of detent.

Note: Damaged threads M 18 x 1.5 in crankshaft journal at the front can be repaired by inserting a helicoil insert 0130 0184027.

12 Install vibration damper, pulley, viscofan and

radiator.

|

|

||||||||||||||||||||||||||||||

|

|

|||||||||||||||||||||||||||||||

|

Note: Take association of pulley on crankshaft for various engines 110 from the following list.

|

|||||||||||||||||||||||||||||||

|

|

|||||||||||||||||||||||||||||||

|

|

||||||||||||||||||||||||||||||

|

|

|||||||||||||||||||||||||||||||

|

03.2 340/4 F 3

|

|||||||||||||||||||||||||||||||

|

|

|||||||||||||||||||||||||||||||

|

|

||||||

|

Pulley

|

Engine

|

|

||||

|

|

||||||

|

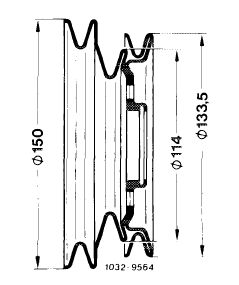

110 466 01 15

|

110.921*

|

|||||

|

110.931* 110.922 version 1 110.032 version 1 110.981* 110.991* 110.982 110.992 110.983 110.993 with special version power steering or air conditioning

|

||||||

|

|

||||||

|

110466 01 15

|

||||||

|

|

||||||

|

Pulley

|

Engine

110.922 version 2 110.932 version 2

110.923 version 1*

110.924 version 1* 110.984 version 1* 110.985 110.986

110.987 versioni* 110.994

|

|

||||

|

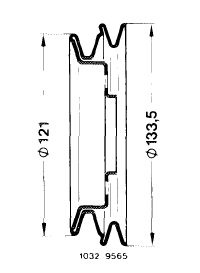

123 032 00 04

|

||||||

|

* with 55 Ah alternator

|

||||||

|

|

||||||

|

123 032 00 04

|

||||||

|

|

||||||

|

Pulley

|

Engine

|

|

||||

|

|

||||||

|

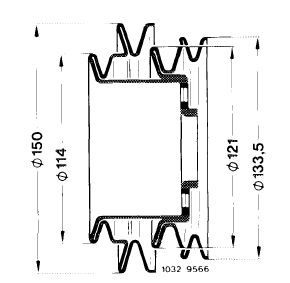

123 032 01 04

|

110.922*

|

|||||

|

110.932* 110.923* 110.924* 110.984* 110.985* 110.986* 110.987* 110.994* * with special version air conditioning or emission control

|

||||||

|

|

||||||

|

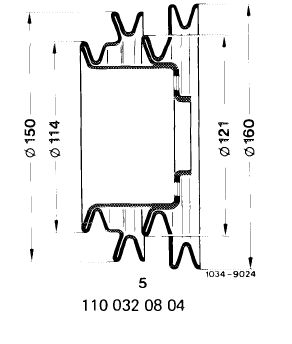

Pulley 110 032 08 041)

Introduction into series C^)August 1978

starting engine end no. starting chassis end no.

|

123 032 01 04

|

|||||

|

||||||

|

110.984-12-043 370 110.985-12-044 308

Introduction into seriesCA

|

123.033-12-043 906 123.053-12-010 554

|

|||||

|

starting engine end no. starting chassis end no.

123.0072) 110.984 -“”0-023 276 123.033 019 600

|

||||||

|

-12-076 809

|

123.053

|

|||||

|

110.985-12-075 271 116.024-157 385

1) Together with 65 Ah alternator

2) (s) only

|

||||||

|

|

||||||

|

03.2-340/5 F 3

|

||||||

|

|

||||||

|

|

|||||||

|

Pulley 110 032 09 04* (formerly 123 032 00 04)

Introduction into series March 1980

starting engine end no. starting chassis end no.

1log23-10-014 965 123.030-029 250 -12-018 195 123.050-003 705

|

|

||||||

|

|

o

CO

|

||||||

|

eg

|

|||||||

|

|

|||||||

|

110.924

|

-10-000 356 -12-001 102

|

126.021-001 320

|

|||||

|

|

|||||||

|

110984 -10-023 276 123.033-073 349 -12-076 809 123.053-019 600

110.985 -12-075 271 126.024/025-157 385

110.987 ~1 °-°00 675 126.022/023-004 070 -12-003 696

* together with 65 Ah alternator

|

|

||||||

|

1034 9208

|

|||||||

|

|

|||||||

|

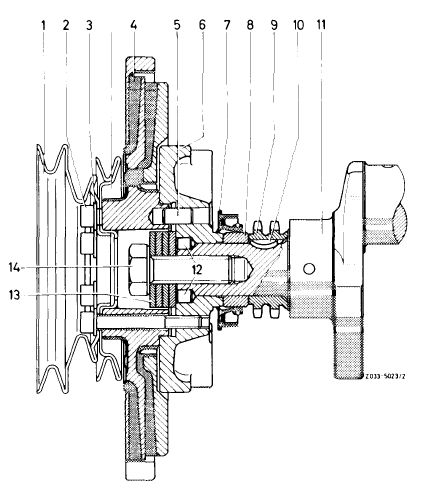

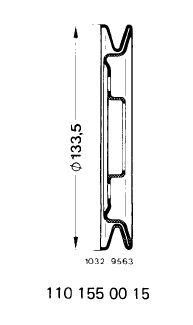

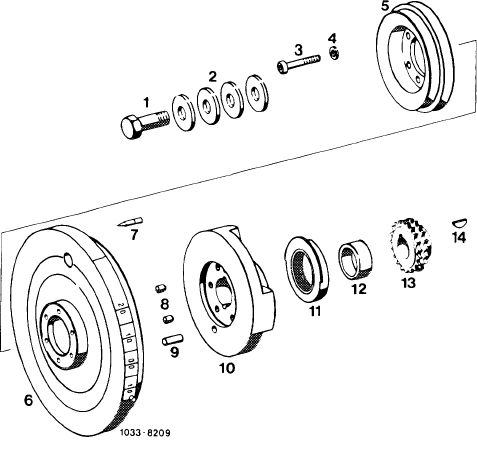

Pulleys, vibration damper and balancing disc

|

|||||||

|

|

|||||||

|

1 Screw M 18 x 1.5 x 45

2 Cup springs

3 6 screws M 8 x 65

4 6 washers 8.4

5 Pulley

6 Vibration damper 254 mm dia

7 Adjustment indicator

8 2 set pins 8×8

9 Cyl. pin 10h8x 18

10 Balancing disc

11 Radial sealing ring 1 2 Spacing ring

13 Crankshaft gear

14 Woodruff key

|

|

||||||

|

|

|||||||

|

03.2-340/6 F2

|

|||||||

|

|

|||||||