Magnetic fan clutch

|

|

|||||

|

20-330 Magnetic fan clutch

|

|||||

|

|

|||||

|

Function

|

E04- 6707

|

||||

|

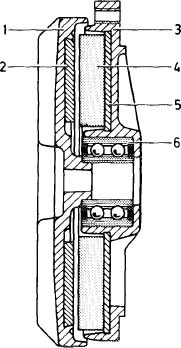

The main parts of a torque controlled magnetic fan clutch are the so-called hysteresis disc (2) made of a permanently magnetized material on the primary or drive side and a disc shaped permanent magnet (4) on the secondary side. Both clutch discs are divided into 8 magnetic segments with 4 each north and south poles, which are opposite each other alternately in a unloaded condition.

When under load both clutch discs will turn agains each other somewhat, so that the magnetic field characteristics receive a component even in circumferential direction and thus transmit a torque of up to 1.8 Nm.

|

|||||

|

|

|||||

|

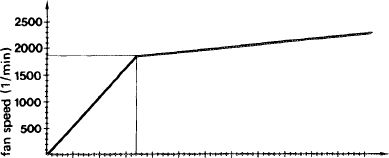

At an engine speed of about 1700/min the fan moment will be higher than the torque transmitted by the magnetic clutch. The clutch “tears off” and begins to slip.

The now existing difference in speed leads to a permanent demagnetization of the hysteresis disc by way of the secondary side permanent magnets. In this manner there is an additional eddy current, because of which the transmitted torque and thus the fan speed will increase slightly as the engine speed increases (as shown in the diagram).

The switching in and off of the fan cannot be heard.

|

1 Primary disc

2 Hysteresis disc

3 Secondary disc

|

4 Permanent magnet

5 Steel disc

6 Bevelled ball bearing

|

|||

|

|||||

|

|

|||||

|

1000 2000 3000

engine speed (1/min)

|

4000 5000 6000

1203-6809

|

||||

|

|

|||||

|

Checking magnetic fan clutch

|

|||||

|

|

|||||

|

To check, turn fan by hand with the engine stopped. There must be a springy, definitely noticeable resistance.

Fan clutches, which can be turned without resistance or produce a noise when turned, are defective and must be replaced.

|

|||||

|

|

|||||

|

20.2-330/1 F3

|

|||||

|

|

|||||

|

|

||

|

Handling magnetic fan clutches

|

||

|

|

||

|

Attention!

The magnetic fan clutch must be removed before performing any work on engine or front end, during which grinding or filing burrs could fall on the fan.

Protect fan clutches against falling or serious knocks.

The magnetic clutch is free of maintenance, cannot be repaired with normal workshop equipment and must never be disassembled. Replace a defective magnetic clutch.

|

||

|

|

||

|

20.2-330/2

|

||

|

|

||