Removal and installation of flywheel and driven plate

|

|

|||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|

03—410 Removal and installation of flywheel and driven plate

|

|||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|

|

|||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|

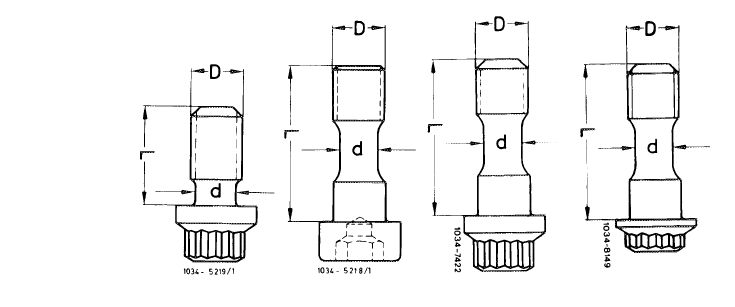

Necked down screws

|

for manual transmission

|

for automatic transmission

|

|||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|

|

|||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|

|||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|

|

|||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|

|||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|

|

|||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|

Initial torque

|

40 Nm

|

||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|

|

|||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|

Necked down screw for driven plate and flywheel

|

|||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|

|

|||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|

Torque angle

|

90-100°

|

||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|

|

|||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|

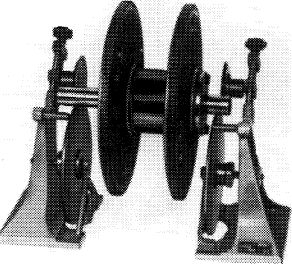

Special tool

|

|||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|

|

|||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|

Detent

|

|

116 589 01 40 00

|

|||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|

|

|||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|

03.2-410/1 F3

|

|||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|

|

|||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|

|

|||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|

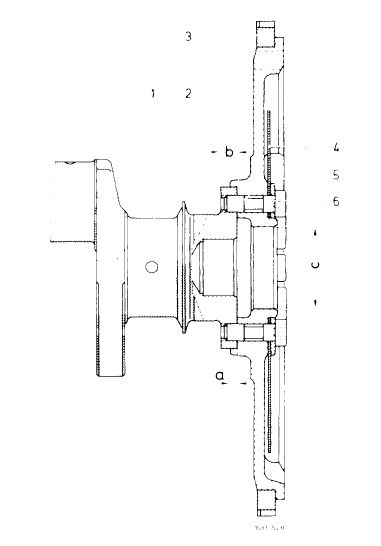

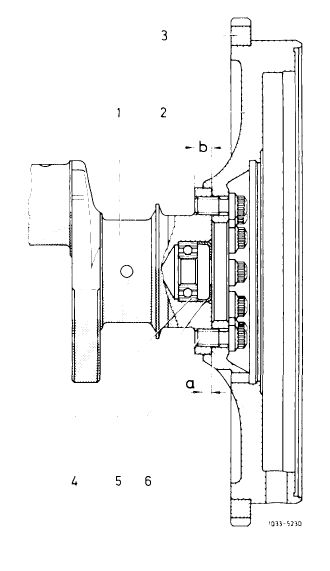

Note

Do not mix up flywheel for automatic transmission of 110 engine with flywheel for automatic transmission of 4-cylinder engines 115 and 615.

Engine 110 dimension a = 4.5 mm

Engine 115 and 615 dimension a = 6.5 mm

On exchange engines, the mounting bore in flywheel of 35 mm dia can be bored to 50.00—50.016 mm dia (50 H6) for transmission with hydraulic clutch (722.200/202).

|

|

||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|

Layout of flywheel and driven plate for automatic transmission

|

|||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|

|||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|

|

|||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|

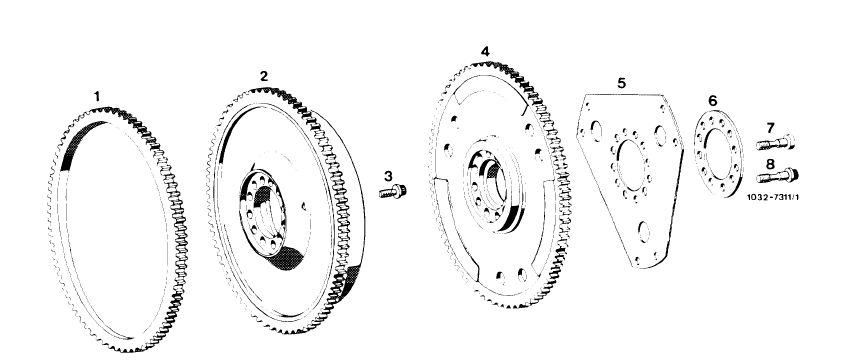

Layout flywheel for manual transmission

|

|

||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|

1 Crankshaft

2 Flywheel

3 Ring gear

4 Ball bearing

|

5 Closing ring

6 Necked down screw a = 5 mm

b = 10 mm

|

||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|

|

|||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|

03.2-410/2 F3

|

|||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|

|

|||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|

|

||||

|

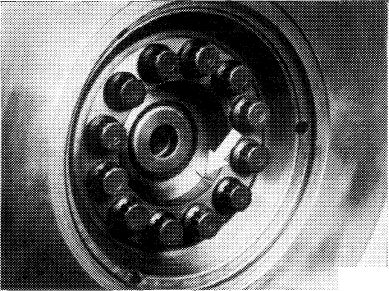

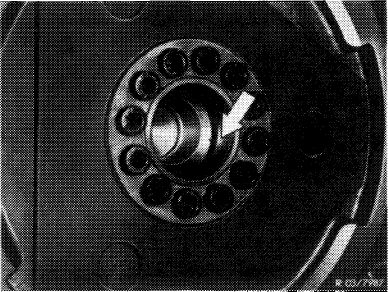

Removal

1 Loosen necked down screws, remove flywheel, driven plate and spacing washer.

Note: The flywheels and the crankshaft are marked together (arrow).

|

£03/7399′

|

|||

|

Flywheel manual transmission

|

||||

|

|

||||

|

Installation

|

|

103-J0648

|

||

|

Note: If a new flywheel is installed, unbalance should be the same as for old flywheel (03—440).

|

||||

|

|

||||

|

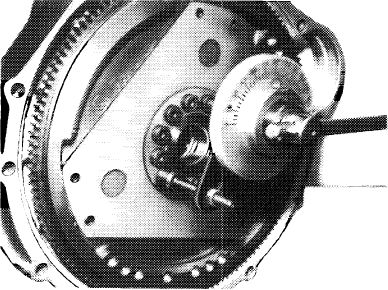

2 Measure necked down dia d of necked down screws.

When the minimum dia is attained, replace necked down screws.

Necked down screws 1st and 2nd version for automatic transmission can be replaced by 3rd version.

|

||||

|

|

||||

|

3 Position flywheel on crankshaft journal in such a manner that the markings (arrow) are in alignment.

|

|

|||

|

Flywheel automatic transmission

|

||||

|

|

||||

|

03.2-410/3 F2

|

||||

|

|

||||

|

|

||||

|

4 Screw-in necked down screws and pre-tighten to 30—40 Nm with torque wrench.

|

||||

|

|

||||

|

5 Complete angle of rotation torque 90—100° by means of angle of rotation wrench.

|

103-8518

|

|||

|

|

||||

|

||||

|

|

||||

|

1 Starter ring gear

2 Flywheel with starter ring gear for manual transmission

3 12 necked down screws

4 Flywheel with starter ring gear for automatic transmission

|

5 Driven plate

6 Spacing ring

7 12 necked down screws 1st version

8 12 necked down screws 2nd and 3rd version

|

|||

|

|

||||

|

03.2-410/4 F3

|

||||

|

|

||||

Nowsze